A converter transformer coil structure with formed angle ring and its manufacturing method

A technology of a converter transformer and a manufacturing method, applied in the directions of transformer/inductor coil/winding/connection, coil manufacturing, coil, etc., which can solve the problems of heat dissipation efficiency reduction, obstruction of insulating oil flow, oil seepage and oil leakage, and coil insulation Problems such as performance degradation and assembly size can prevent the appearance from bulging, eliminate hidden dangers of oil flow and oil leakage, and have a good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following in conjunction with the accompanying drawings, embodiments of the present invention are described in detail.

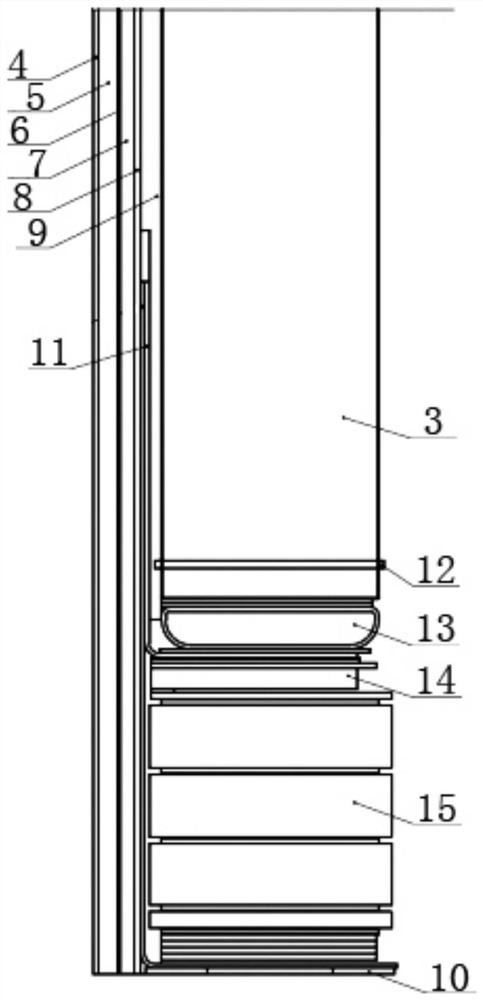

[0022] as Figure 1 Shown, is a local cross-sectional view of the coil structure of an embodiment of the present invention ( Figure 1 The center left side is the inner diameter side of the coil, and the right side is the outside diameter side of the coil). A converter transformer coil structure with a formed angle ring, comprising: coil body 3, coil body 3 is provided with a coil oil path gasket 12, the lower end of the coil body 3, provided with an electrostatic ring 13. The inner diameter side of the coil body 3 is set sequentially: the first layer of cardboard 4, the first layer of bracing 5, the second layer of cardboard 6, the second layer of bracing 7, cardboard tube 8, forming angle ring 11, the main brace 9. The main brace 9 is arranged closely to the inner diameter of the coil body 3, mainly playing the role of an axial oil channel.

[0023] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com