A quick-detachable oiling device for copper cloth

An oil injection device and quick-release technology, which is applied in the direction of lubricating oil control valve, engine lubrication, lubricating parts, etc., can solve the problem that the gap between the copper cloth and the boring row becomes larger, the service life of the copper cloth becomes shorter, and the increase Economic cost and other issues, to achieve the effect of increasing the quality of boring, improving the service life and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

[0018] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

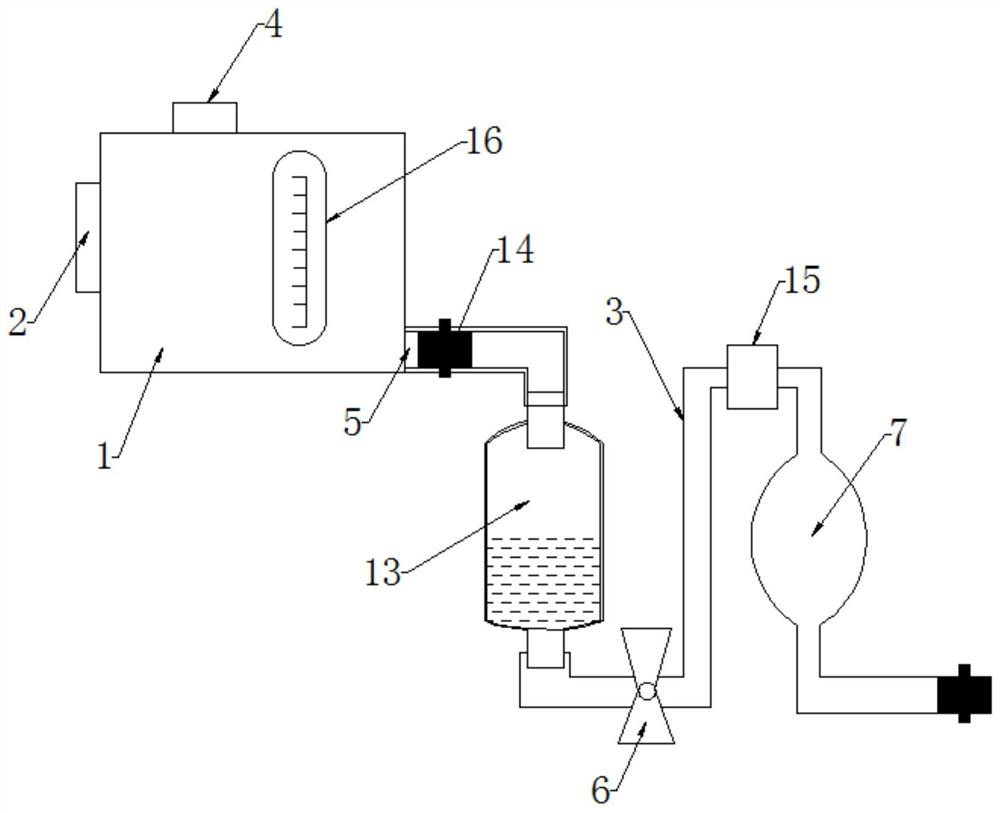

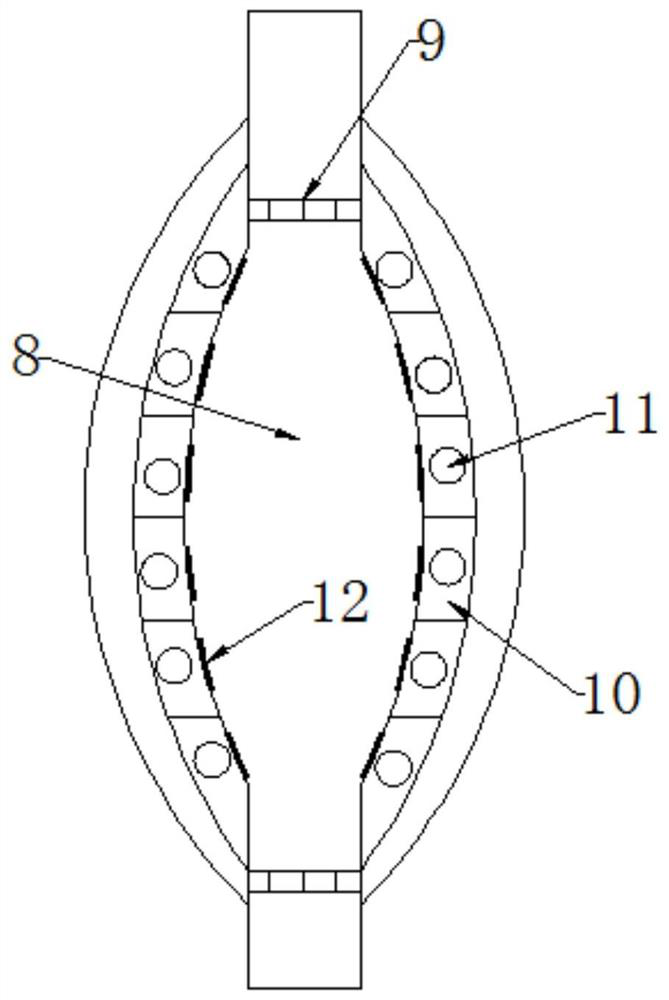

[0019] Such as figure 1 , 2 As shown, the present invention is a quick-release oiling device for copper cloth, including a fuel tank 1, a fixed magnetic sheet 2 and a transparent oiling pipeline 3; the oil tank is connected to the copper cloth through a fixed magnetic sheet; The upper end of the fuel tank is provided with an oil filling port 4, and the lower end of the fuel tank is provided with an oil outlet 5, and the oil outlet is connected to the oil injection port of the copper cloth through the oil injection pipeline, and the ball valve 6 and the oil quantity Adjustment parts.

[0020] The oil volume regulator is an oil volume adjustment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com