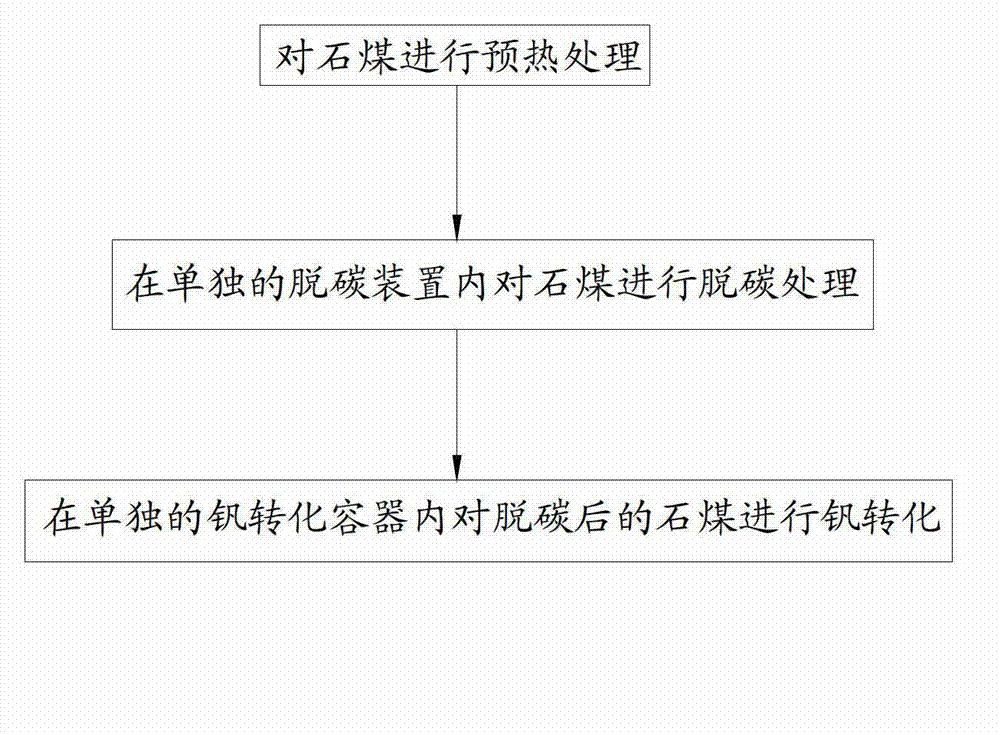

Roasting process for extracting vanadium from stone coal

A roasting process, stone coal technology, applied in the field of roasting process for extracting vanadium from stone coal, can solve the problems of poor effect, influence on oxidation effect, high oxygen consumption, etc., and achieve the effect of avoiding mutual restriction, good roasting effect and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

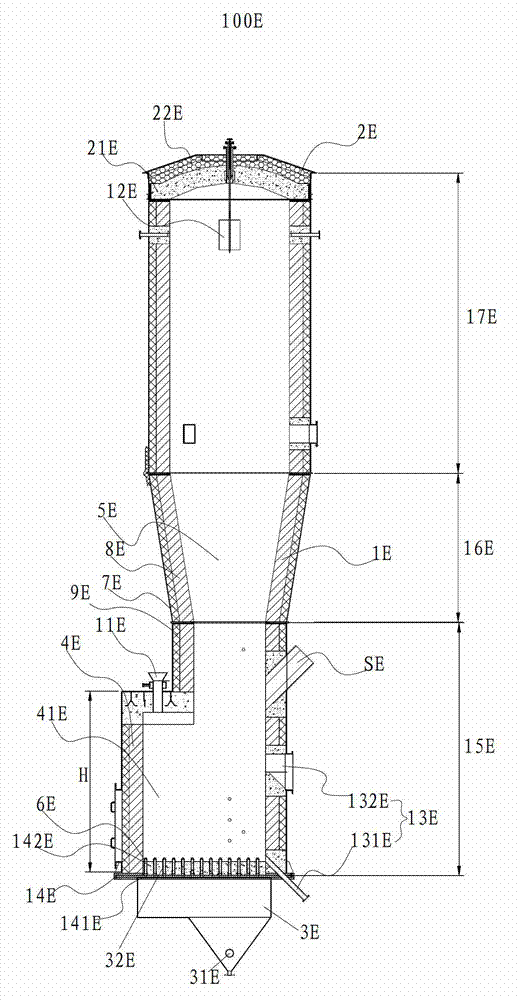

[0031] In this embodiment, the decarburization device is a fluidized fluidized fluidized furnace, and the vanadium conversion device is a rotary kiln 200 . Wherein the rotary kiln 200 is connected with the fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized fluidized furnace" is used to transform the stone coal roasted and decarburized in the fluidized fluidized fluidized fluidized fluidized fluidized fluidized f...

no. 2 example

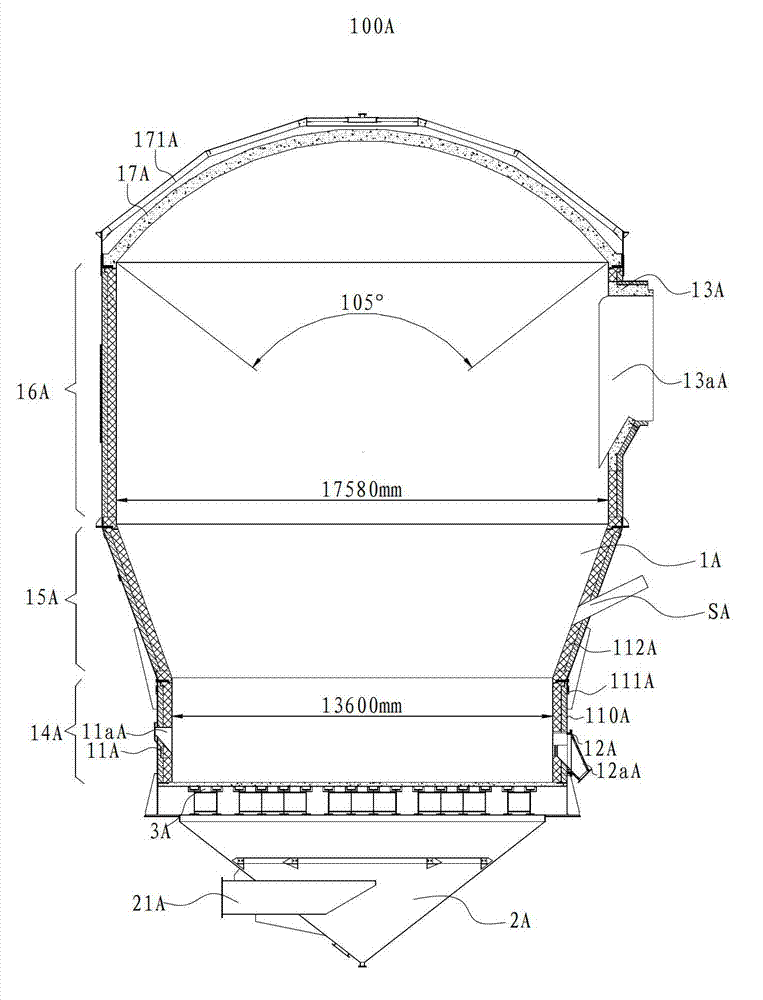

[0073] In this embodiment, both the decarburization unit and the vanadium conversion unit are fluidized fluidized fluidized furnaces.

[0074] Optionally, the decarbonization unit for decarbonization of stone coal has the same structure as the vanadium conversion unit for vanadium conversion. That is to say, the decarburization unit and the vanadium conversion unit can both be as described above figure 2 The example shown in the fluidized fluidized fluidized boiling furnace. Of course, the decarburization unit and the vanadium conversion unit can both be as above-mentioned image 3 The example shown in the fluidized fluidized fluidized boiling furnace.

[0075] Optionally, the decarburization unit for stone coal decarbonization has a different structure than the vanadium conversion unit for vanadium conversion. It can be understood here that the decarburization device can be as above figure 2 The fluidized fluidized fluidized fluidized furnace of the embodiment shown in,...

no. 3 example

[0078] In this embodiment, the decarbonization device is a stone coal combustion chamber 300, and the vanadium conversion device is a rotary kiln 200, wherein the rotary kiln 200 is such as Figure 4 The rotary kiln shown in.

[0079] like Figure 5 As shown, the stone coal combustion chamber 300 has a stone coal feed port 301 and a stone coal discharge port 302 for adding stone coal, and the stone coal combustion chamber 300 is provided with a combustion chamber for injecting fuel and air into the stone coal combustion chamber 300. chamber nozzle 400. Add stone coal from the stone coal feeding port 301 , and inject fuel and air into the stone coal combustion chamber 300 from the combustion chamber nozzle 400 , so that the stone coal undergoes decarbonization reaction in the stone coal combustion chamber 300 . Specifically, such as Figure 5 As shown, the fuel is fed into the coal combustion chamber 300 through the combustion chamber nozzle 400 , and at the same time, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com