LED (Light-Emitting Diode) lamp with ducted convection radiating channel

A heat dissipation channel and LED lamp technology, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of insufficient heat dissipation, large radiator size, and power failure, etc., to achieve Enhance the ability of air convection heat dissipation, increase the heat dissipation area, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

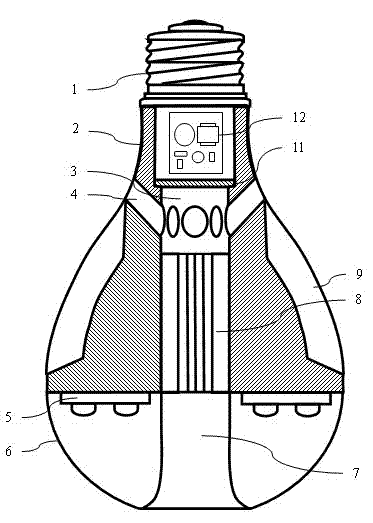

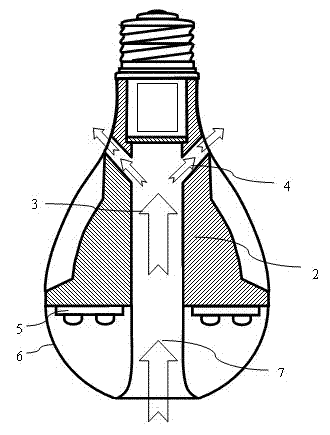

[0015] like figure 1 As shown, the present invention has an LED lamp with a ducted convective heat dissipation channel, including a lamp cap 1, a heat dissipation lamp body 2, an LED light source 5, a light distribution lampshade 6, a partition 11 and a driving circuit 12; the heat dissipation lamp body 2 is hollow and annular , the upper end is connected with the lamp cap 1; the heat dissipation lamp body 2, the lamp cap 1 and the partition 11 form a cavity, the driving circuit 12 is located in this cavity, one end is connected with the lamp cap 1, and the other end is connected with the LED light source 5; the LED light source 5 is distributed in a ring At the bottom of the heat dissipation lamp holder 2, it is covered and sealed by the light distribution lampshade 6.

[0016] The heat dissipation lamp holder 2 is made of metal, plastic, etc., and is provided with an inner hole 3 and a plurality of ventilation holes 4 connected with the inner hole 3; the ventilation holes 4 ...

Embodiment 2

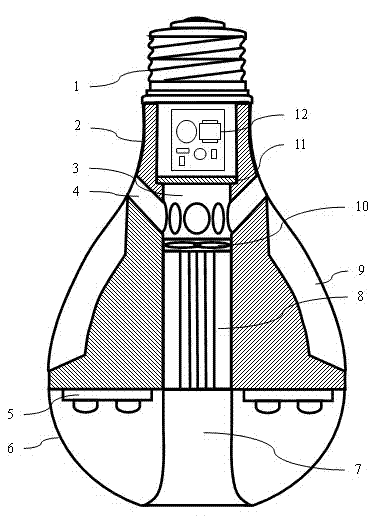

[0021] like image 3 As shown, the difference between the structure of this embodiment and that of Embodiment 1 is that a fan 10 is installed on the top of the inner cooling fin 8 of the inner hole 3 , and the fan 10 is connected to a driving circuit 12 . The fan 10 can greatly accelerate the air flow in the duct, thereby accelerating heat dissipation without increasing the volume of the LED lamp. In this embodiment, the cooperative design of the fan 10 and the duct can realize an LED lamp with small size and high power.

[0022] like Figure 4 As shown, the present invention arranges the outer heat dissipation fins 9 on the heat dissipation lamp body 2, and also arranges the inner heat dissipation fins 8 along the hole wall in the inner hole 3, which increases the heat dissipation area and helps the fixed fan 10 at the same time. . The light distribution lampshade 6 adopts a ring-shaped curved surface design, and uses frosted, film-coated and other uniform light design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com