Plate element, and friction clutch device and brake device provided with plate element

A component and plate-like technology, which is applied in the fields of friction clutch devices and braking devices, can solve the problems of insufficiency of functional fluid media, inability to fully exert the cooling function and dust removal function of plate-like components and clutch friction plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

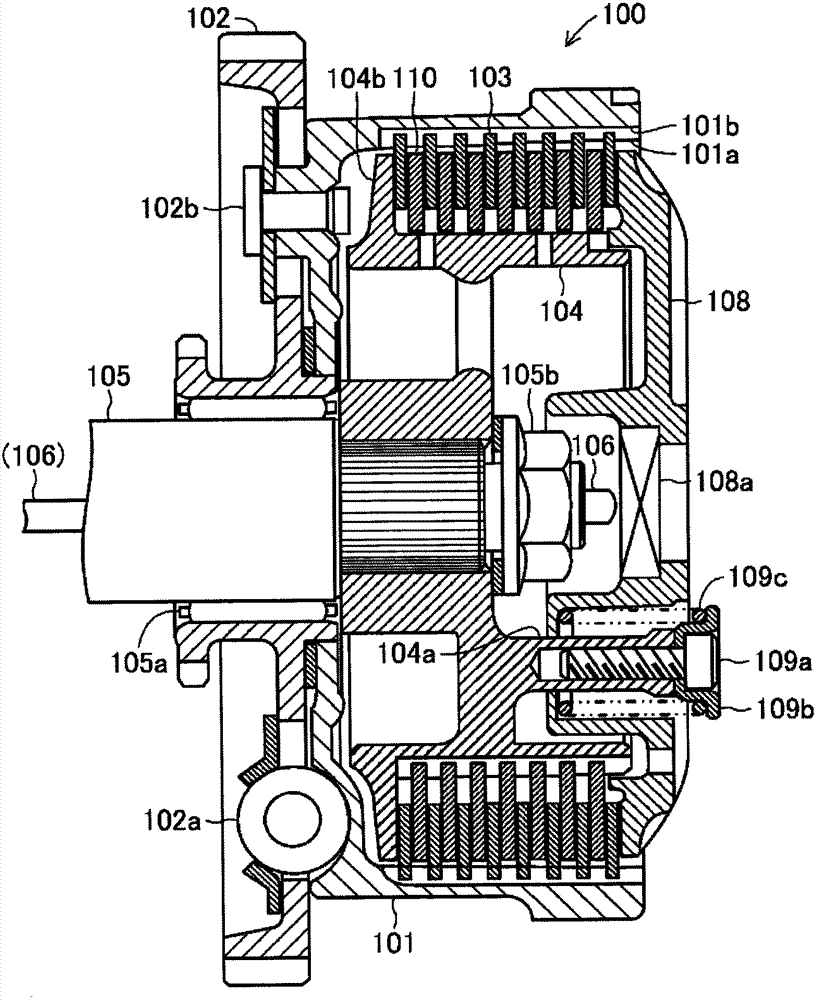

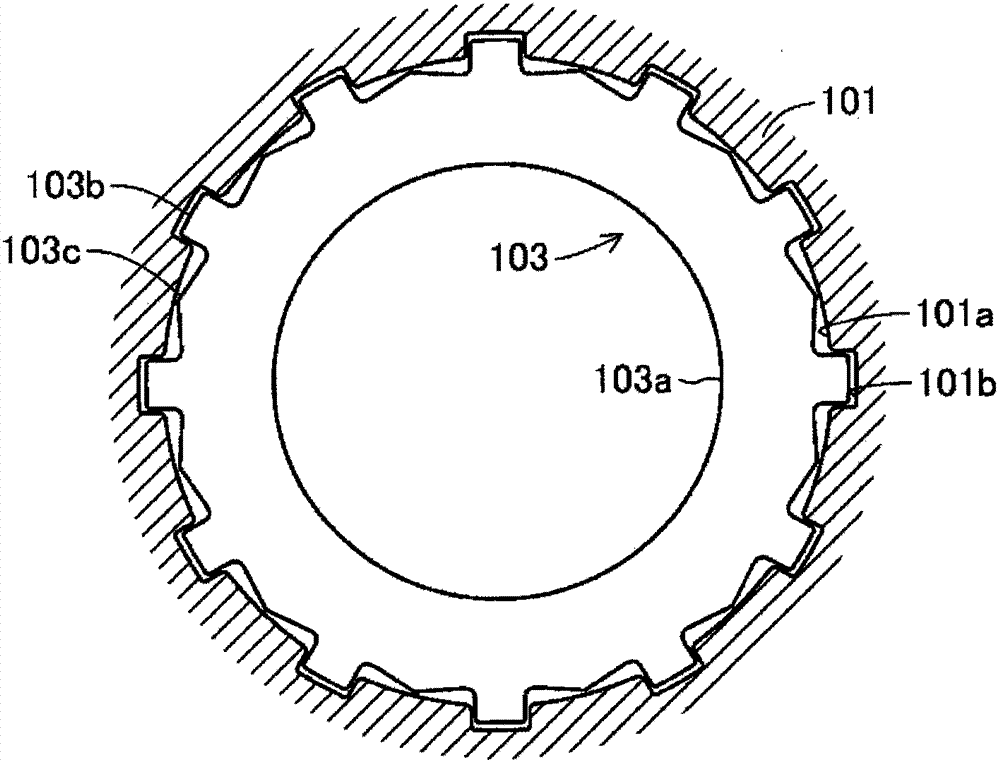

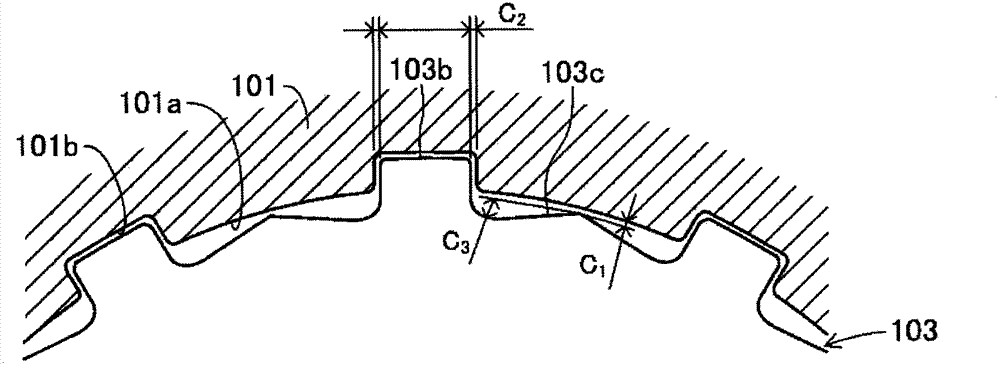

[0034] Hereinafter, embodiments of the plate-shaped assembly and the friction clutch device having the plate-shaped assembly according to the present invention will be described with reference to the drawings. figure 1 It is a cross-sectional view showing the overall configuration of a friction clutch device 100 having a clutch plate 103 as a clutch plate-shaped assembly of the present invention. In addition, in each drawing referred to in this specification, in order to facilitate understanding of this invention, some components are exaggerated and they are schematically shown. Therefore, there may be differences in dimensions, ratios, and the like between the constituent elements. The friction clutch device 100 is used to transmit the driving force of the engine (not shown in the figure) of the prime mover of the two-wheeled motor vehicle (motorcycle) to the wheel (not shown in the figure) of the driven member or to disconnect the driving force. A mechanical device disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com