Online sliver separating device for high moisture content cut tobaccos and separating method of online sliver separating device

A technology of high water content and separation device, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems affecting the effect of wind selection and rejection of stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

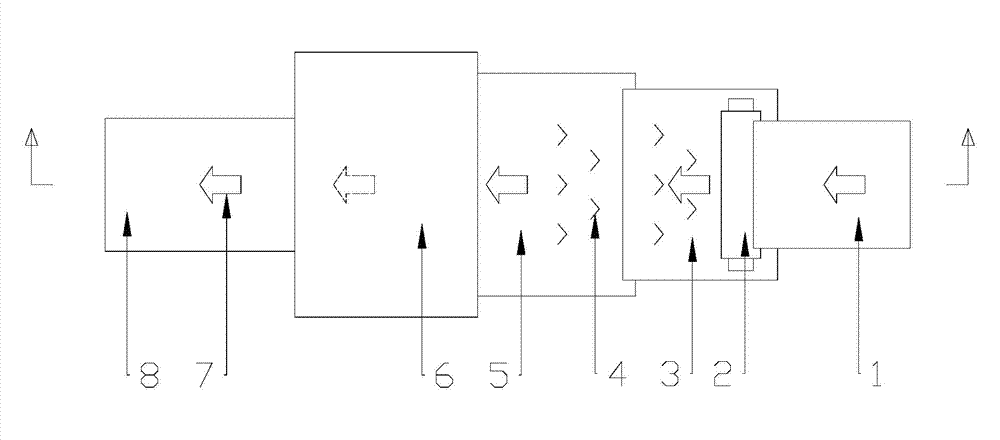

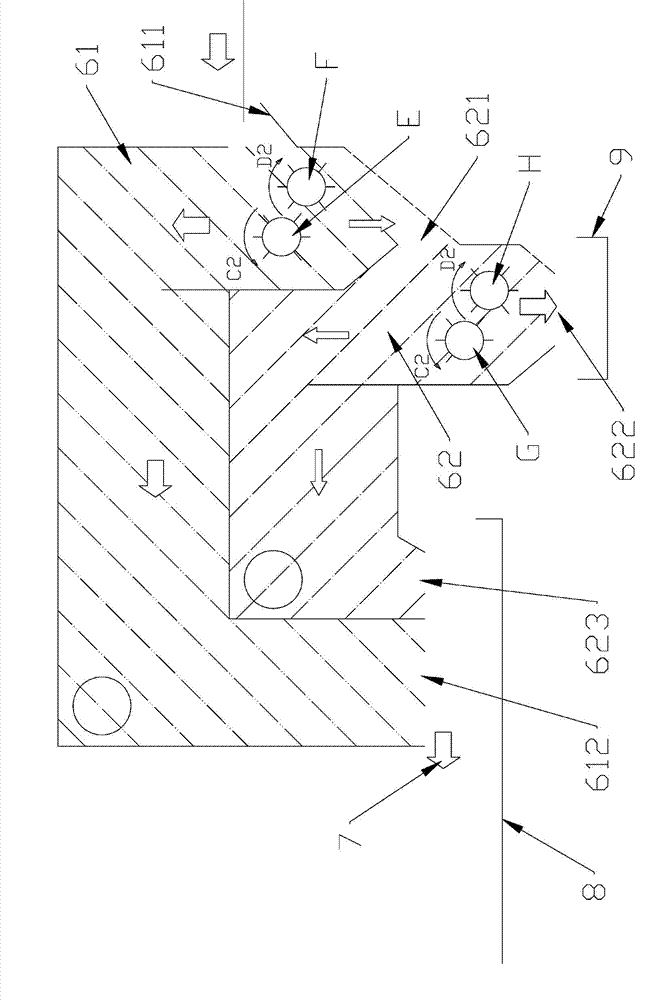

[0021] Such as figure 1 An online stem separation device for shredded tobacco with high moisture content is shown, the device is sequentially provided with a feeding vibrating tank 1, a shredded tobacco opener 2, a high-frequency vibrating tank 3, and a feeding vibrating tank along the conveying direction 7 of the shredded tobacco 5. Two-stage wind separator 6 and discharge vibrating tank 8. The high-frequency vibrating tank 3, or the feeding vibrating tank 5 and the high-frequency vibrating tank 3 are provided with a plurality of shredded tobacco dispersion guide plates 4. The shredded tobacco dispersing guide plate 4 plays the role of enlarging the shredded tobacco breadth, thinning the shredded tobacco layer, and making the shredded tobacco conveying process be in the effect of fluffy state.

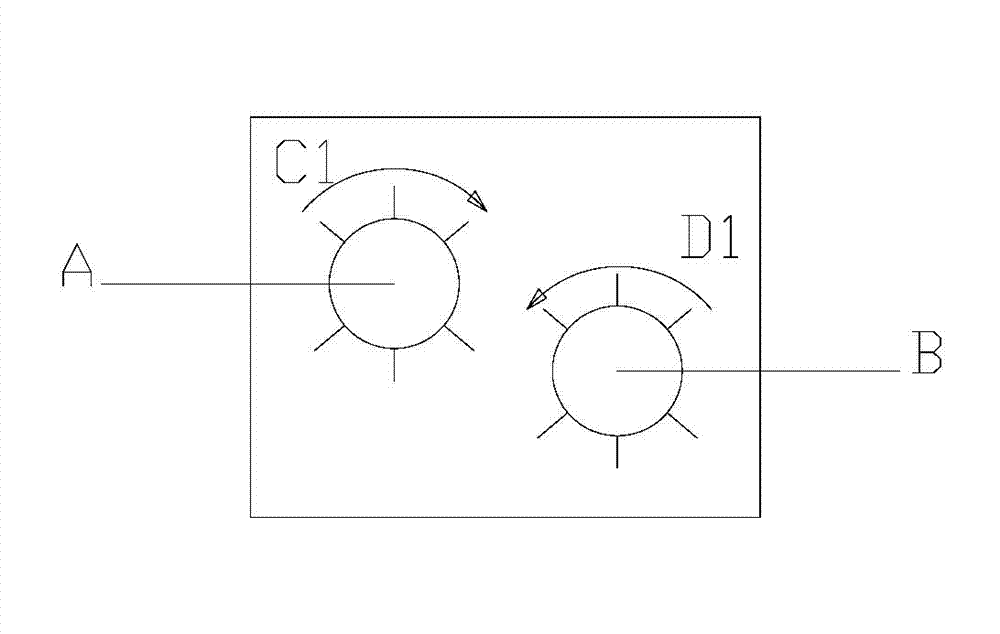

[0022] The two-stage wind separator 6 is composed of first and second selectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com