Ceramic pot

A ceramic pot and ferromagnetic technology, applied in the field of ceramic pots, can solve the problems of low efficiency and unenvironmental protection of ceramic pots, and achieve the effects of satisfying cooking needs, improving utilization rate, and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

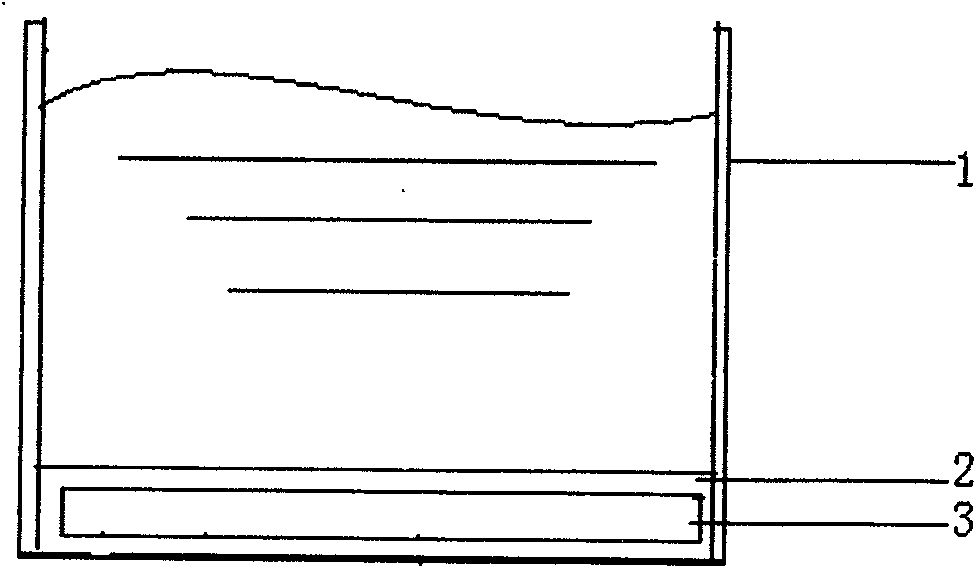

[0013] exist figure 1 In the method, the bottom (2) of the ceramic pot (1) is embedded with a circular ferromagnetic sheet (3), and the area of the circular ferromagnetic sheet (3) is the same as the area of the bottom of the ceramic pot (1).

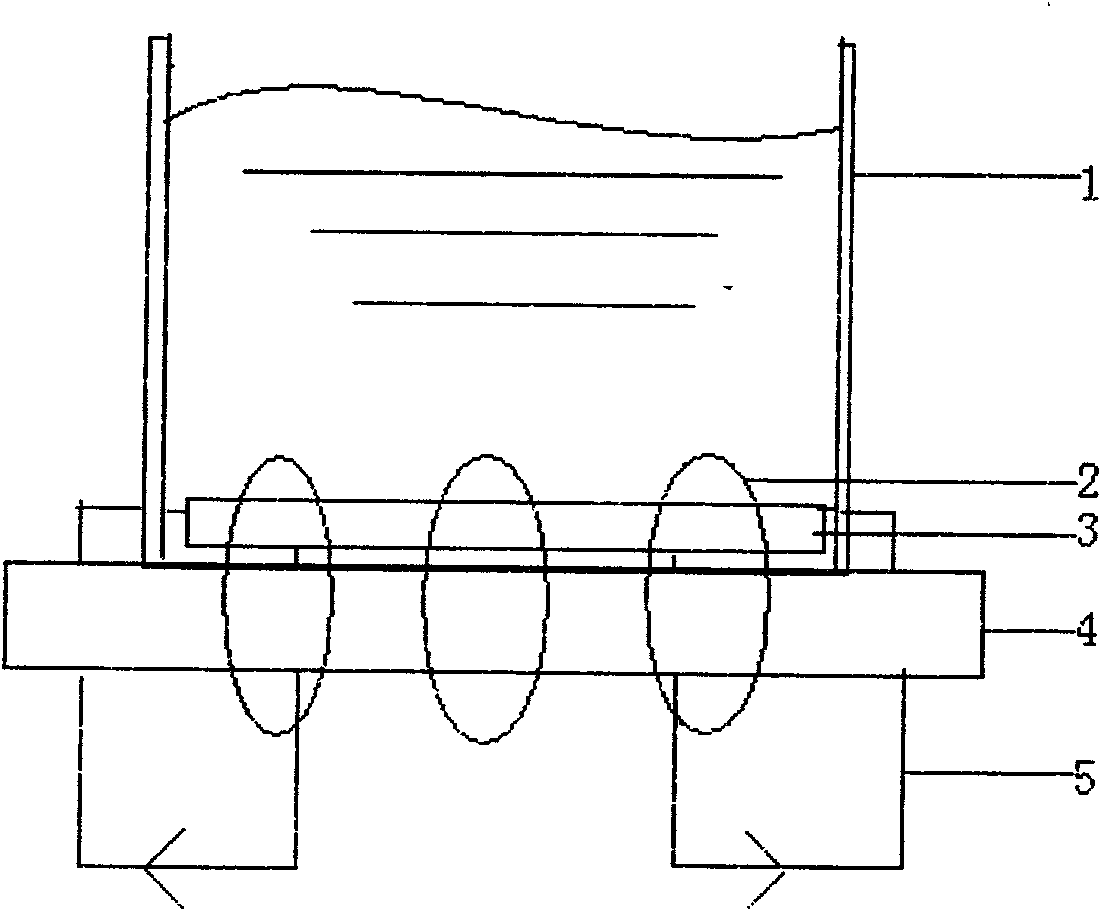

[0014] exist figure 2 , the ceramic pot (1) is placed on the induction cooker heating panel (4). After the induction cooker starts working, the ferromagnetic sheet (3) at the bottom of the ceramic pot cuts the alternating magnetic ring (5) under the action of the alternating magnetic ring (5) of the induction cooker to generate eddy currents (2) on the ferromagnetic sheet (3), The eddy current (2) causes the iron atoms on the ferromagnetic sheet (3) to move irregularly at high speed, and the atoms collide and rub against each other to generate heat energy. After the ferromagnetic sheet (3) generates heat at high speed by itself, eddy currents (2) are generated on the ceramic pot (1) sheet (3) through heat conduction, and the eddy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com