Ultra-micro small-particle size aerosol generating equipment capable of accurately controlling concentration

An aerosol generation and precise control technology, applied in the directions of dissolution, liquid injection device, mixer, etc., can solve the problems of restricting the development of scientific research, different sizes, and harsh liquid requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

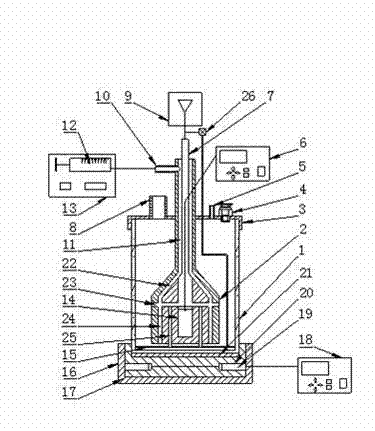

[0039] When using an ultra-fine particle size aerosol generating device that can accurately control the concentration of the present invention and cooperate with a fixed volume airtight cabin to complete the gas environment experiment research of the ultra-fine particle size aerosol that can accurately control the concentration, all items must be prepared in advance. The detection instrument, according to the required ultra-fine particle size range, selects the glass chamber 1 that is suitable for the height, installs and seals the upper cap body 3, and connects the pipeline from the aerosol output pipe 8 to a fixed-volume airtight cabin. The required atomized liquid is injected into the syringe 12 and connected to the main liquid inlet port 10, the syringe 12 is placed on the precision syringe pump 13, the flow rate of the atomized liquid is pre-programmed on the precision syringe pump 13, and the compressed air is adjusted. Intake air flow rate, adjust the electric temperatur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap