Vertical rice tool device of rice milling machine

A rice milling machine and rice knife technology, applied in the field of rice milling machines, can solve the problems of increasing the spacing of rice milling chambers, large longitudinal surfaces, and high energy consumption, and achieve the effects of increasing friction, reducing costs, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

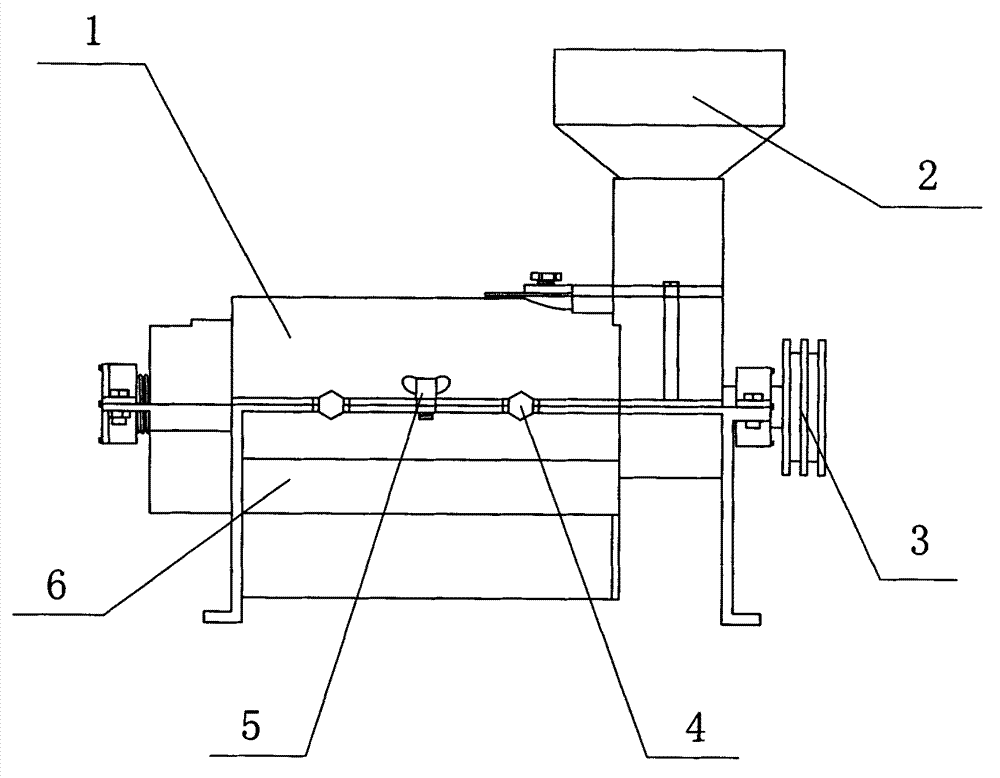

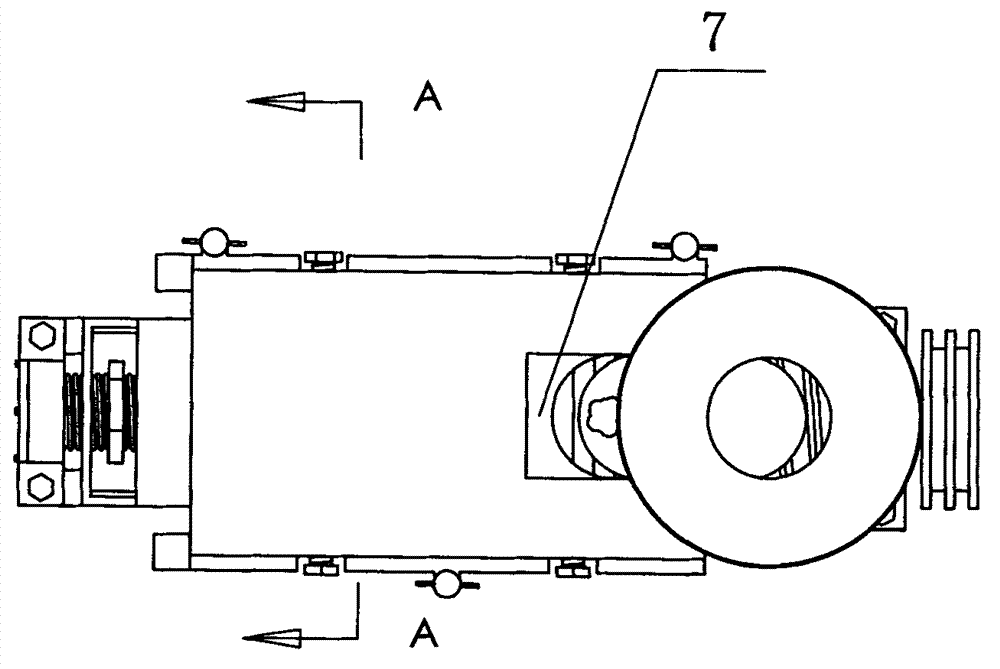

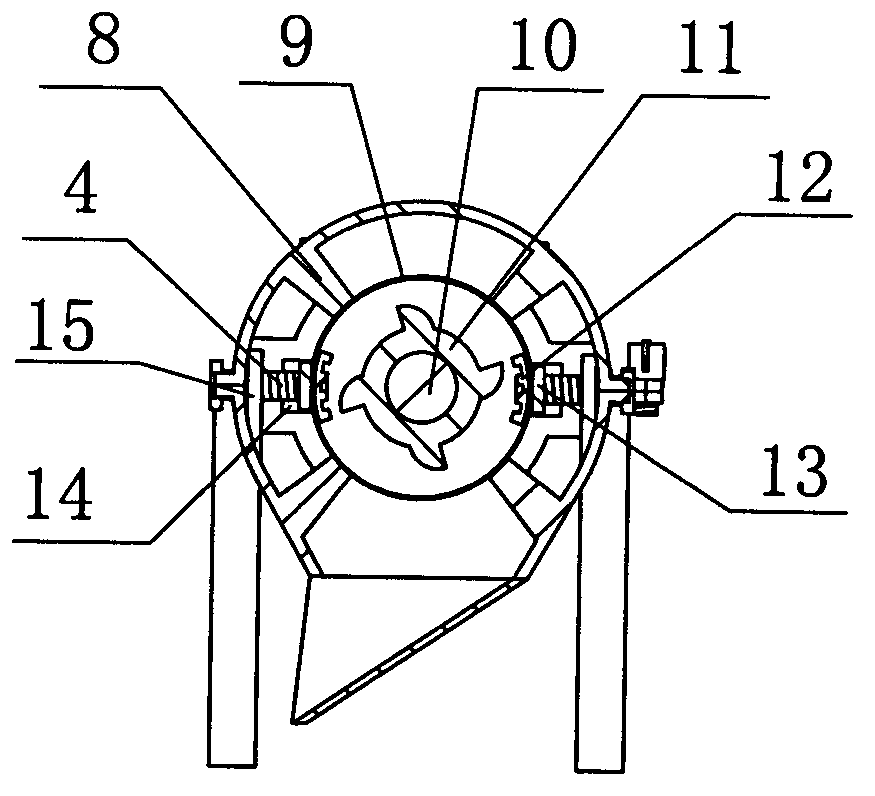

[0022] Embodiment 1: refer to Figure 1 to Figure 10 As shown, a vertical rice cutter device of a rice milling machine includes an upper casing, a lower frame, a rice cutter board, a rice cutter attached board, a rice sieve, and a grain feeding funnel, wherein the inside of the rice cutter board 12 Be provided with 3-8 convex edge rice knives 16 and rice knife groove 17, rice knife plate 12 is contained in the rice milling room both sides, perpendicular to the diameter of the rice milling room, every convex edge rice knife 16 on the rice knife plate 12 Equivalent to a rice knife of the original rice machine, the mixture of grain, rice and bran can be continuously contacted, rubbed and squeezed with a plurality of convex rice 16 in the rice milling room, and the chaff can be peeled off with light pressure. The brown rice is whitened, the rice is made into strips, the temperature rise of the rice is low, the power of the ratio is small, the energy consumption is low, and the ser...

Embodiment 2

[0023] Embodiment 2: refer to Figure 11 , Figure 12 As shown, a vertical rice cutter device of a rice milling machine has the same overall structure as that in Embodiment 1, except that the rice cutter plate 12 is provided with a toothed rice cutter 20 with 3-10 rows of teeth.

Embodiment 3

[0024] Embodiment 3: refer to Figure 13 , Figure 14 As shown, a vertical rice cutter device of a rice milling machine has the same overall structure as that of Embodiment 1, except that the rice cutter plate 12 is provided with a mesh-shaped rice cutter 21 with a mesh groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com