3D pattern plastic shell processing technology

A technology of plastic casing and processing technology, which is applied in the field of 3D pattern plastic casing processing technology, and can solve problems such as poor 3D visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

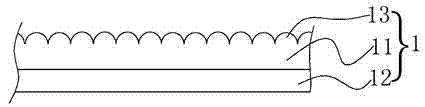

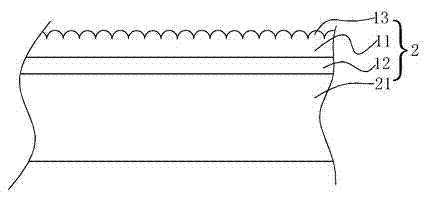

[0019] figure 1 A 3D pattern sheet according to one embodiment of the present invention is schematically shown.

[0020] The 3D pattern sheet 1 used in this kind of 3D pattern plastic casing processing technology includes a resin film layer 11 and a 3D-treated pattern layer 12. The resin film layer 11 of the 3D pattern sheet 1 is made of PVC resin, PET resin or PP resin. become. There is a grating 13 on the outer side of the resin film layer 11, and the grating 13 is formed by UV offset printing, extrusion molding or heat pressing. The grating 13 density of the resin film layer 11 of the 3D pattern sheet 1 is 70 lines, 75 lines, 90 lines, 100 lines, 161 lines or 200 lines. The pattern layer 12 is printed on the inside of the resin film layer 11 .

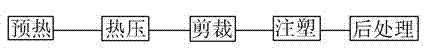

[0021] The 3D pattern plastic shell processing technology includes preheating, hot pressing, cutting, inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com