Caterpillar multi-sucker wall-climbing robot

A technology of a wall-climbing robot and multiple suction cups is applied in the field of wall-climbing robots, which can solve the problems of no independent suction cups, reduced energy utilization efficiency, and reduced vacuum degree of a public vacuum source, etc., and achieves the effect of improving the wall-climbing speed and saving electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

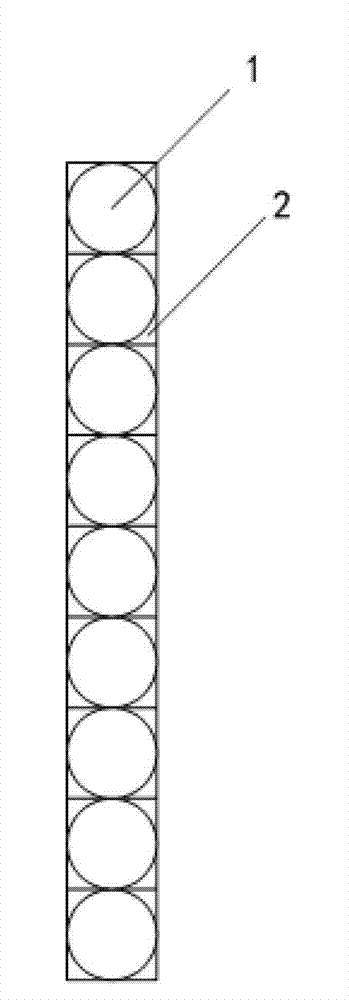

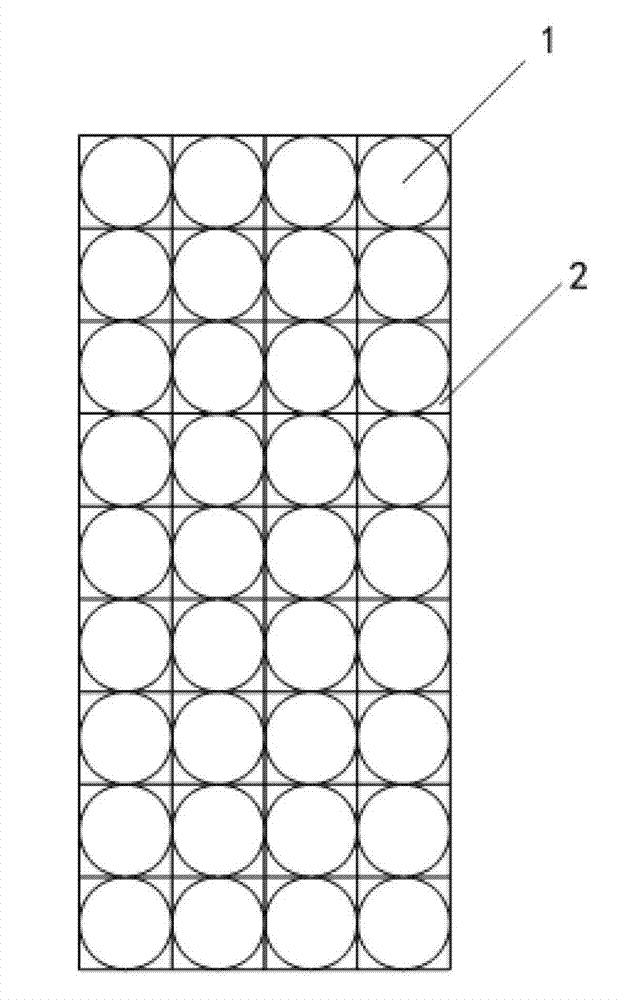

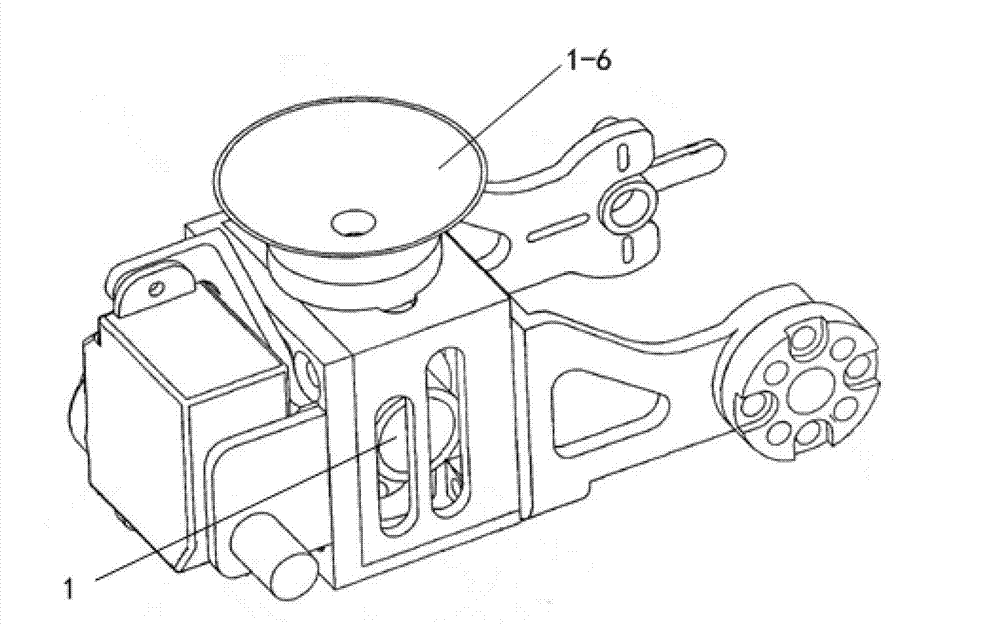

[0032] Such as Figure 1-3 , a crawler-type wall-climbing robot with multiple suction cups, comprising: crawlers; it also includes: a normally closed electromagnetic vacuum chuck 1 suitable for being in a state to be adsorbed when powered on, and in an adsorbed state when powered off; The vacuum chucks 1 are evenly distributed on the track 2; it also includes a sucker control circuit, which is suitable for controlling the power-off of each electromagnetic vacuum chuck 1 that is in a suspended state and in contact with the curtain wall when the track 2 is rolling, and at the same time controls the contact Or the electromagnetic vacuum chuck that is about to leave the curtain wall is energized 1 .

[0033] The uniform distribution of the electromagnetic vacuum chuck 1 on the crawler belt 2 can be uniform distribution in the horizontal direction, or a uniform distribution in a matrix; or a crawler belt 2 composed of several adsorption joints with the same structure, and each adso...

Embodiment 2

[0048] See Figure 1-6 , on the basis of embodiment 1, the crawling method of the wall-climbing robot includes:

[0049] ① Initially, the sucker control circuit of the wall-climbing robot controls the electromagnetic coil 1-3 of the electromagnetic vacuum chuck 1 to be in a power-off state;

[0050] ② When the first sensor 3-1A located at the bottom of the front end of the wall-climbing robot detects that an electromagnetic vacuum chuck 1 on the crawler belt 2 is close to the curtain wall surface, the sucker control circuit controls the movement of the electromagnetic vacuum chuck 1 The electromagnetic coil 1-3 is energized, that is, the electromagnetic coil 1-3 attracts the piston 1-2 and drives the rubber sucker 1-6 to be in a state to be adsorbed, that is, the electromagnetic vacuum chuck 1 is in a state to be adsorbed; when the After the first sensor 3-1A detects that the electromagnetic vacuum chuck 1 is completely attached to the curtain wall, the chuck control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com