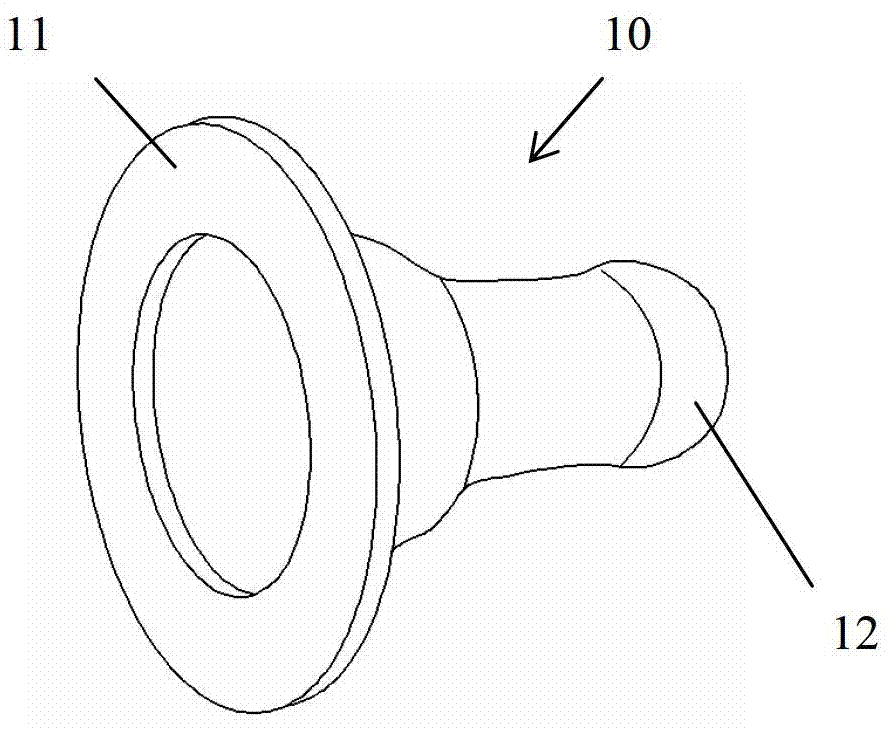

Nipple feeding mechanism and automatic nipple finishing equipment

A technology for automatic sorting and pacifiers, which is applied in packaging and other directions, can solve the problems of pacifiers without automatic sorting and irregular shapes, etc., and achieve the effect of automatic sorting and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

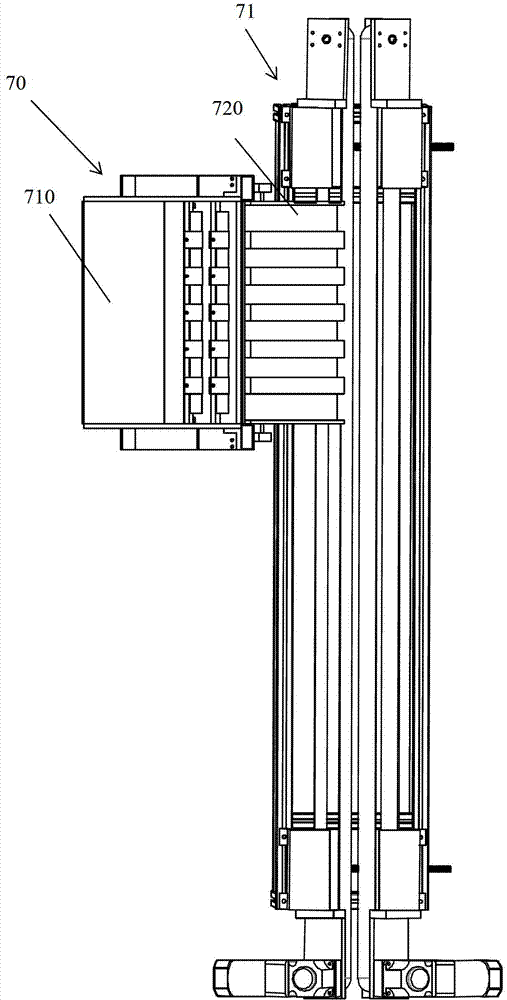

[0026] Such as figure 2 As shown, the automatic pacifier sorting device of the present invention includes a pacifier feeding mechanism 70 and a pacifier finishing mechanism 71 .

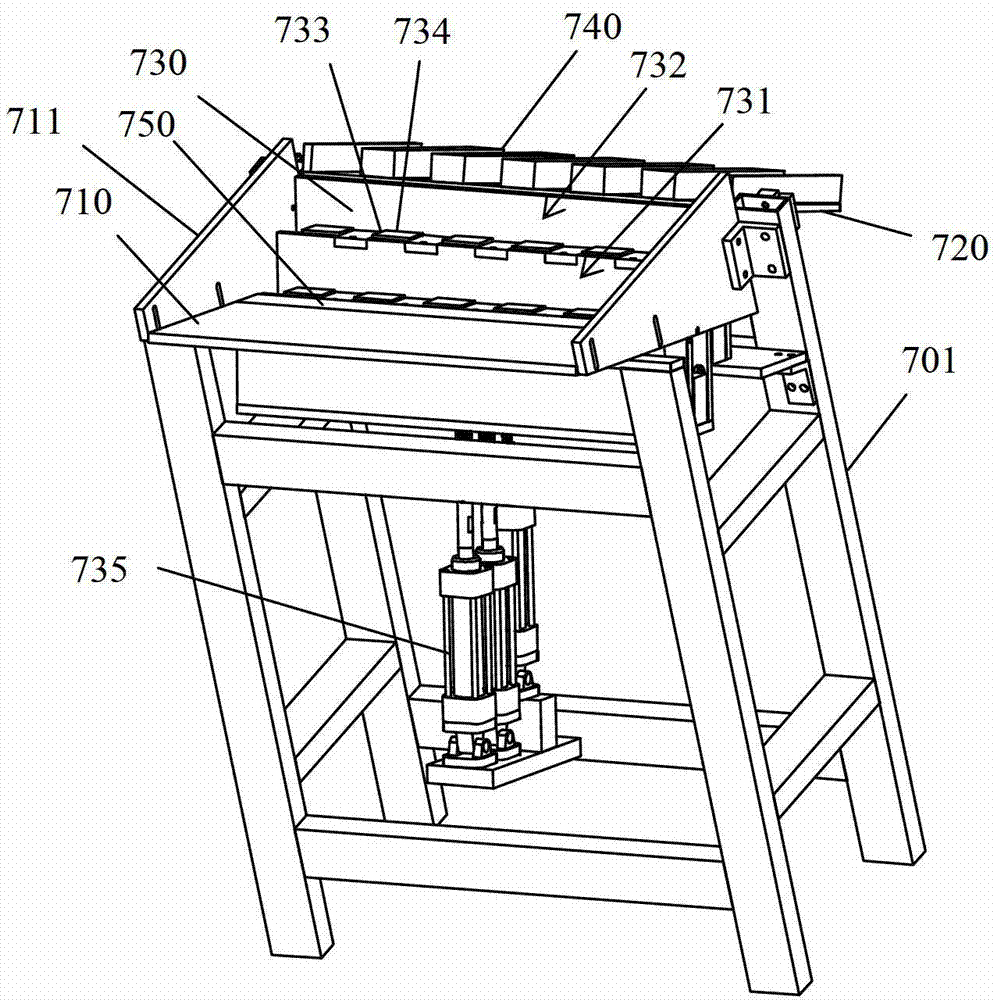

[0027] Another example image 3 , 4 As shown, wherein, the feeding mechanism 70 includes a frame 701, and a first vibration ramp plate 710, a second vibration ramp plate 720, a ladder 730 and a bar stopper 740 on the frame 701 are provided.

[0028] Wherein, the bottom end of the first vibration ramp plate 710 extends to the bottom of the step 730 , and side baffles 711 are provided on both sides of the first vibration ramp plate 710 . The upper end of the second vibration ramp plate 702 is connected to the top of the step 730 .

[0029] Wherein, the ladder 730 is a two-stage ladder, and the width of the surface of the ladder is slightly larger than the size of a pacifier, which can just accommodate a pacifier. Push block holes 733 are evenly spaced on the step surface of each step (namely the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com