A special-shaped prefabricated beam for bridges

A prefabricated beam and special-shaped technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as difficult quality control, heavy beams, slow production progress, etc., to avoid hidden dangers in grouting quality, low equipment requirements, and molds The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

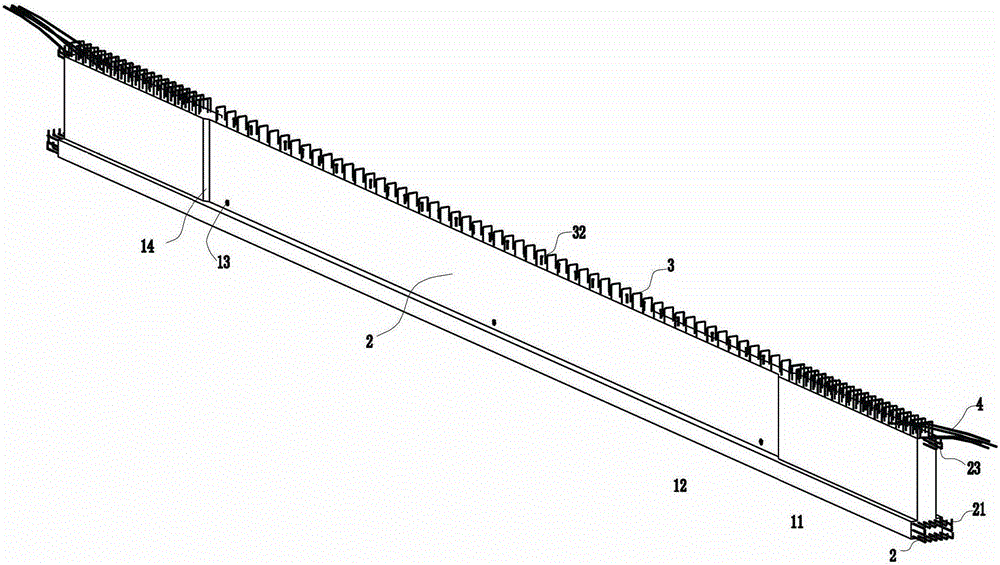

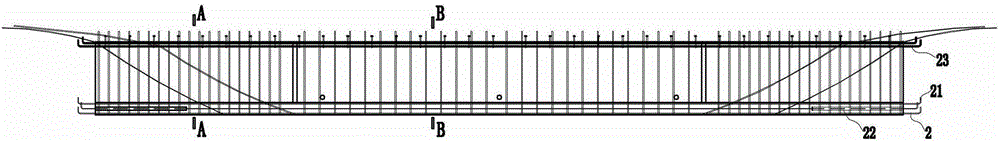

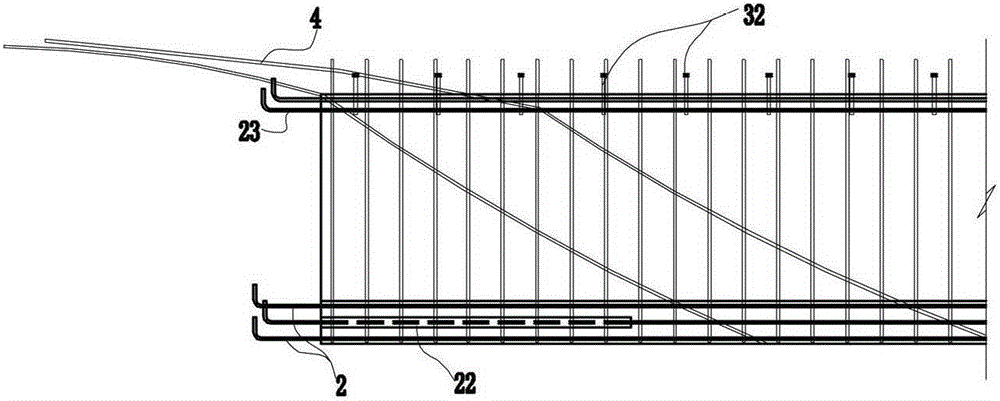

[0025] see Figure 1 to Figure 5 According to an embodiment of a special-shaped prefabricated beam used for bridges provided by the present invention, it includes an inverted T-shaped beam body 1 and a prestressed steel strand 2 embedded in the lower part of the beam body 1 as the main reinforcement, and the beam body 1 includes a web 11 and a lower flange 12, the web 11 is provided with stirrups 3, the part of the stirrups 3 protrudes from the upper surface of the beam body 1, and the lower part of the web 11 of the beam body 1 Through-holes 13 passing through the main ribs of the transverse partition are arranged at a certain distance in the longitudinal direction. The lower flange 12 in the prefabricated beam of the present invention mainly bears the pressure after the prestressed tendons are stretched, and at the same time bears the pressure under the action of negative bending moment at the end of the beam after being laminated into a continuous beam, so its width is larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com