Non-connection reinforcing steel bar construction method

A construction method and steel bar technology, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of high connection costs, etc., and achieve the effects of reducing construction costs, using the technology conveniently, and saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

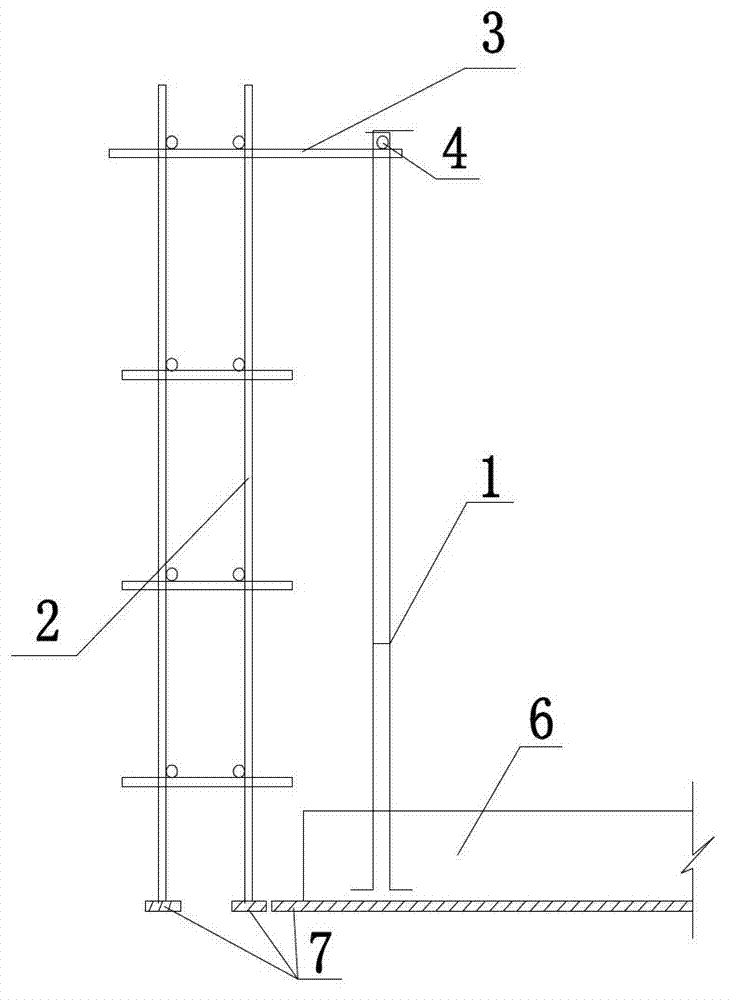

[0017] (1) After completing the construction of the basement foundation cushion 7, set up double-row scaffolding 2 around the outside of the basement foundation in the foundation steel bar binding process; 3. The plurality of steel bar hangers 3 protrude 600mm toward the inner side of the basement foundation; the distance between adjacent steel bar hangers 3 is 1900mm. (3) connect the steel bar hangers 3 on the same side with a longitudinal hanging rod 4 at the front end 50 mm away from a plurality of steel bar hangers 3; The other end is hung on the vertical hanging rod 4 that has been set up, so that the foundation of the basement and the vertical steel bar 1 of the basement can be buried once without connection.

[0018] This method is used to connect in place at one time, and compared with the traditional method, the cost of vertical steel bar connection is saved by 46,000 yuan.

Embodiment 2

[0020] (1) After completing the construction of the basement foundation cushion 7, set up double-row scaffolding 2 around the outside of the basement foundation in the foundation steel bar binding process; 3. The plurality of steel bar hangers 3 protrude 700mm toward the inner side of the basement foundation; the distance between adjacent steel bar hangers 3 is 2000mm. (3) Connect the steel bar hangers 3 on the same side with a longitudinal hanging rod 4 at a distance of 55mm from the front ends of a plurality of steel bar hangers 3; The other end is hung on the vertical hanging rod 4 that has been set up, so that the foundation of the basement and the vertical steel bar 1 of the basement can be buried once without connection.

[0021] This method is used to connect in place at one time, and compared with the traditional method, the cost of vertical steel bar connection is saved by 53,000 yuan.

Embodiment 3

[0023] (1) After completing the construction of the basement foundation cushion 7, set up double-row scaffolding 2 around the outside of the basement foundation in the foundation steel bar binding process; 3. The plurality of steel bar hangers 3 protrude 650mm toward the inner side of the basement foundation; the distance between adjacent steel bar hangers 3 is 1950mm. (3) Connect the steel bar hangers 3 on the same side with a longitudinal hanging rod 4 at a distance of 45mm from the front ends of the multiple steel bar hangers 3; The other end is hung on the vertical hanging rod 4 that has been set up, so that the foundation of the basement and the vertical steel bar 1 of the basement can be buried once without connection.

[0024] This method is used to connect in place at one time, and compared with the traditional method, the cost of vertical steel bar connection is saved by 75,000 yuan.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap