Gear shift support

A shift lever, shift arm technology, applied in the direction of elements with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of reduced operating comfort, complicated structure of shift hoses and selector hoses, etc. problem, to achieve the effect of convenient vehicle layout, simple structure and flexible rod-to-rod ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

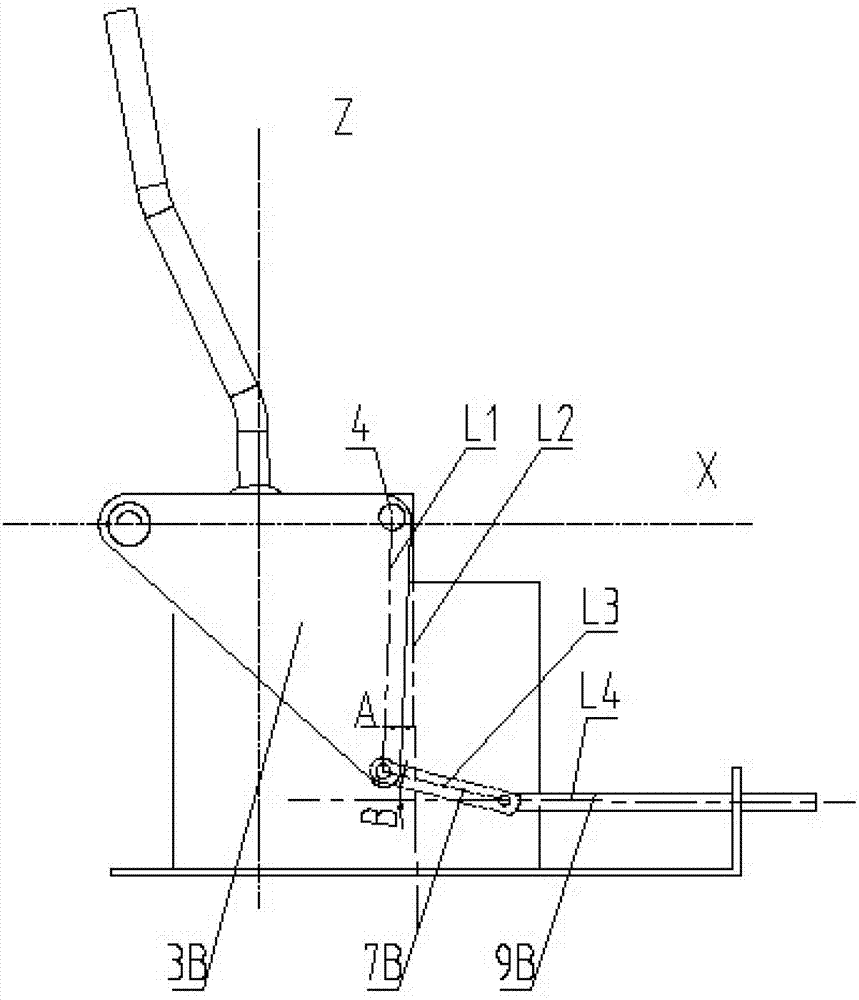

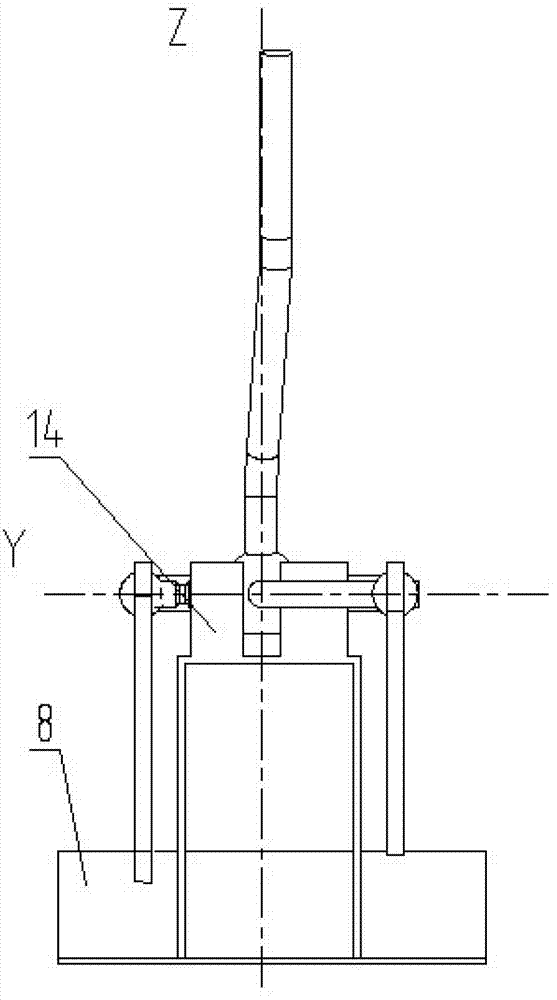

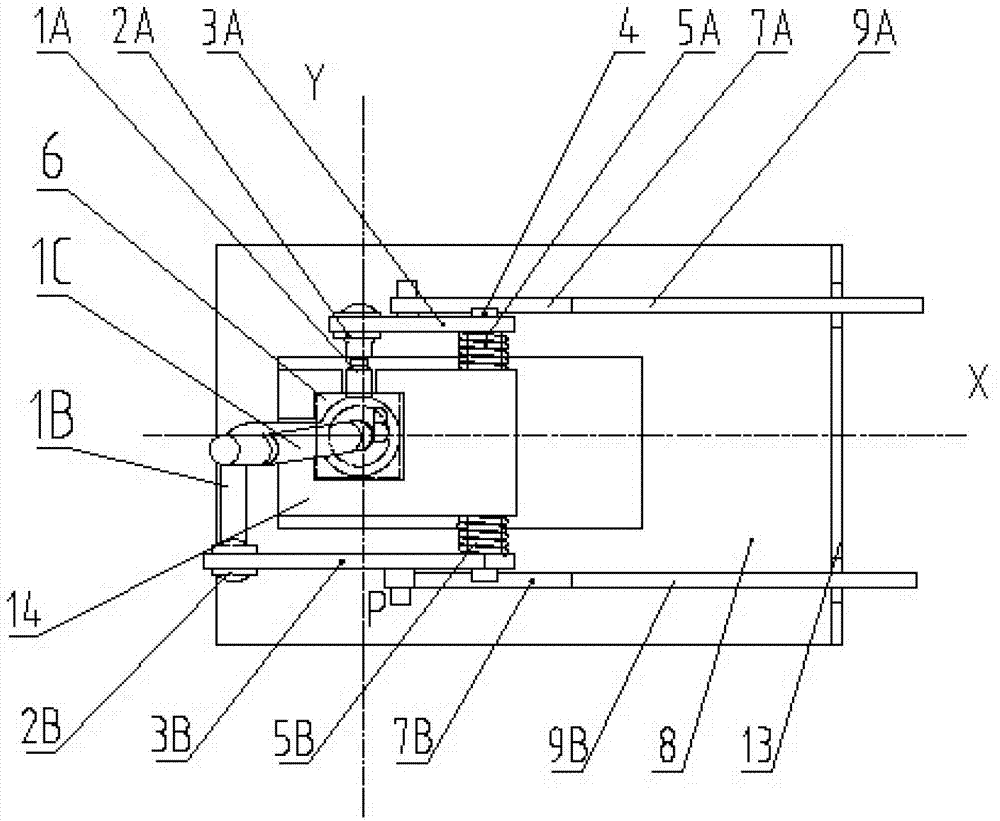

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0024] Such as Figure 1 to Figure 4 As shown, a shift support includes a support body 8, a raised rotating bush installation part 14 is arranged on the support body 8, a rotating bush 6 is arranged inside the rotating bush installation part 14, and the rotating bush 6 is provided with a shift lever assembly.

[0025] The shift rod assembly includes a shift rod 1C and a selector arm 1A and a shift arm 1B connected to the shift rod 1C. The gear selection arm 1A protrudes from the rotating bush installation part 14 along the Y direction, and the shift arm 1B extends out of the rotating bush installation part 14 along the X direction, and then extends in the -Y direction after being bent at 90°. X, Y, Z directions such as Figure 1 to Figure 3 defined in .

[0026] The rear end of the rotating bush installation part 14 opposite to the shift arm 1B is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com