LED project lamp using lamp shell support as mounting interface support structure

A technology for LED floodlights and installation interfaces, which is applied to components of lighting devices, cooling/heating devices of lighting devices, light sources, etc., and can solve the problems of high manufacturing cost, non-common use, and small batches of LED lighting products , to achieve the effect of facilitating standardized large-scale production, high versatility and interchangeability, low cost and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

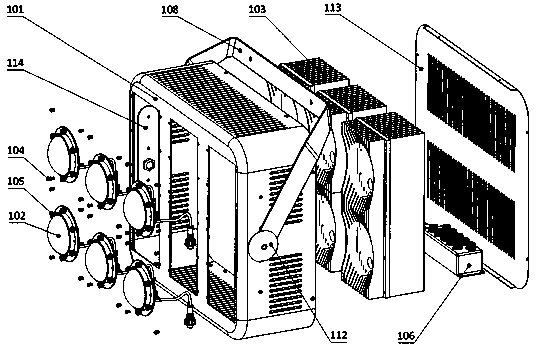

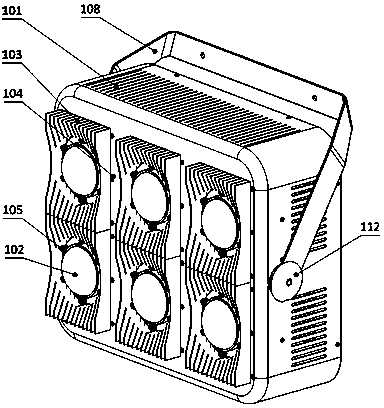

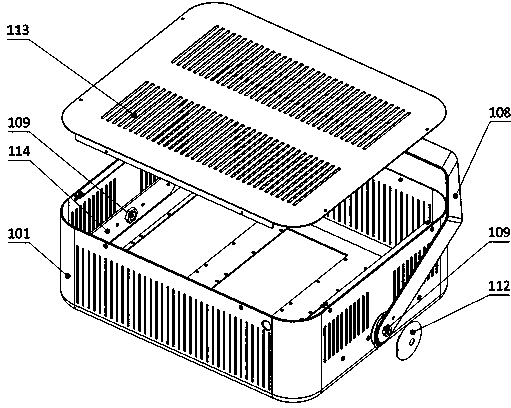

[0060] An LED flood light using a lamp housing bracket as an installation interface bracket structure, such as figure 1 , figure 2 and image 3 As shown, it includes a lamp housing bracket 101 and an LED bulb 102. The lamp housing bracket 101 is a rectangular box with an opening on one side. The lamp housing bracket 101 is provided with an extruded double-sided radiator 103. The lamp housing bracket 101 is opposite to the opening. There are openings on the surface for installing the extruded double-sided radiator 103. The lamp housing bracket 101 is provided with ventilation holes on the other surfaces except the opening and the side with the opening. The lamp housing bracket 101 is arranged on the two sides. The fixing components on the side are installed and fixed; the extruded double-sided heat sink 103 is provided with an installation interface for installing the LED bulb 102 . The fixing assembly includes a lamp fixing bracket 108 and a reinforcing plate 114, the reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com