Method for diagnosing failure of wind-powered rotary support based on wavelet analysis

A technology of slewing bearings and wavelet analysis, which is applied to the fault diagnosis of low-speed and heavy-duty slewing bearings, and in the field of fault diagnosis of wind power slewing bearings based on wavelet analysis, which can solve problems such as acceleration and achieve the effect of solving inaccurate fault identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

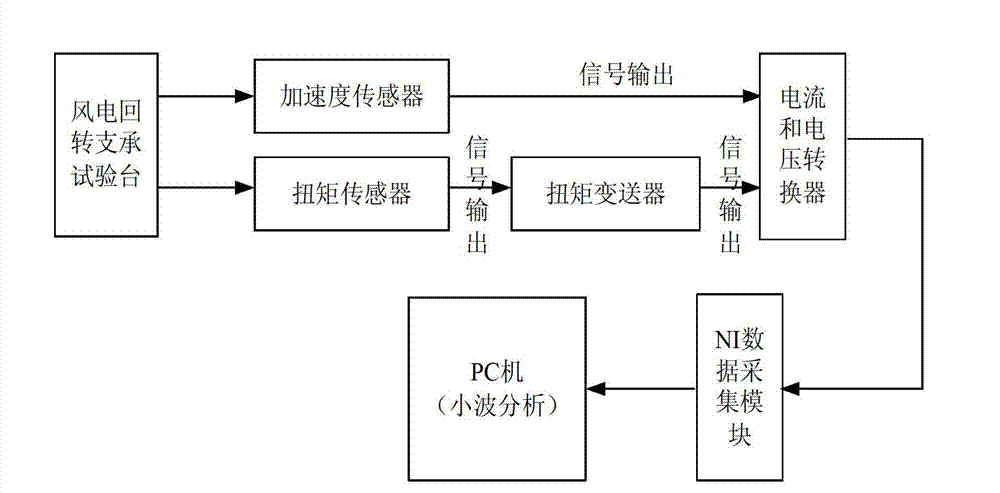

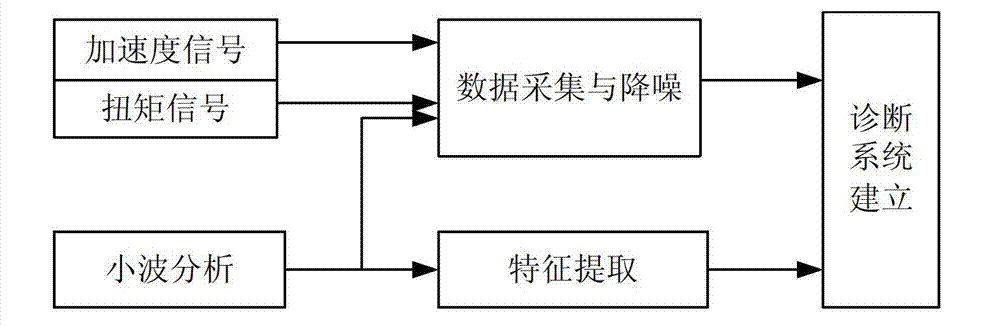

[0064] A method for fault diagnosis of wind power slewing bearings based on wavelet analysis, comprising the following steps:

[0065] a) Acceleration signals and torque signals of early wind power slewing bearing faults are extracted through acceleration sensors and torque sensors;

[0066] b) Transmit the torque signal through the transmitter, and convert the transmitted torque signal and acceleration signal through the current and voltage conversion board;

[0067] c) Enter the NI data acquisition module, select the appropriate wavelet basis function, and use the wavelet analysis method to decompose the fault signal in multiple scales;

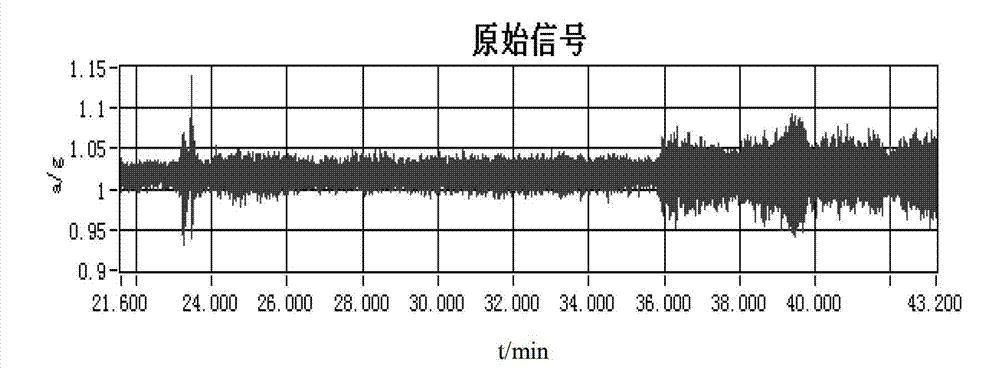

[0068] d) Extract the fine features of the fault signal from the decomposed and reconstructed waveforms and their spectrograms at various scales;

[0069] e) To determine the type of failure or the time of failure.

[0070] The selection of an appropriate wavelet basis function described in step c includes the following steps:

[0071] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com