Bag dust remover

A technology of bag dust collector and dust bag, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of numerous components, complex structure, and high manufacturing cost of bag dust collectors, so as to simplify the structure and reduce the manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

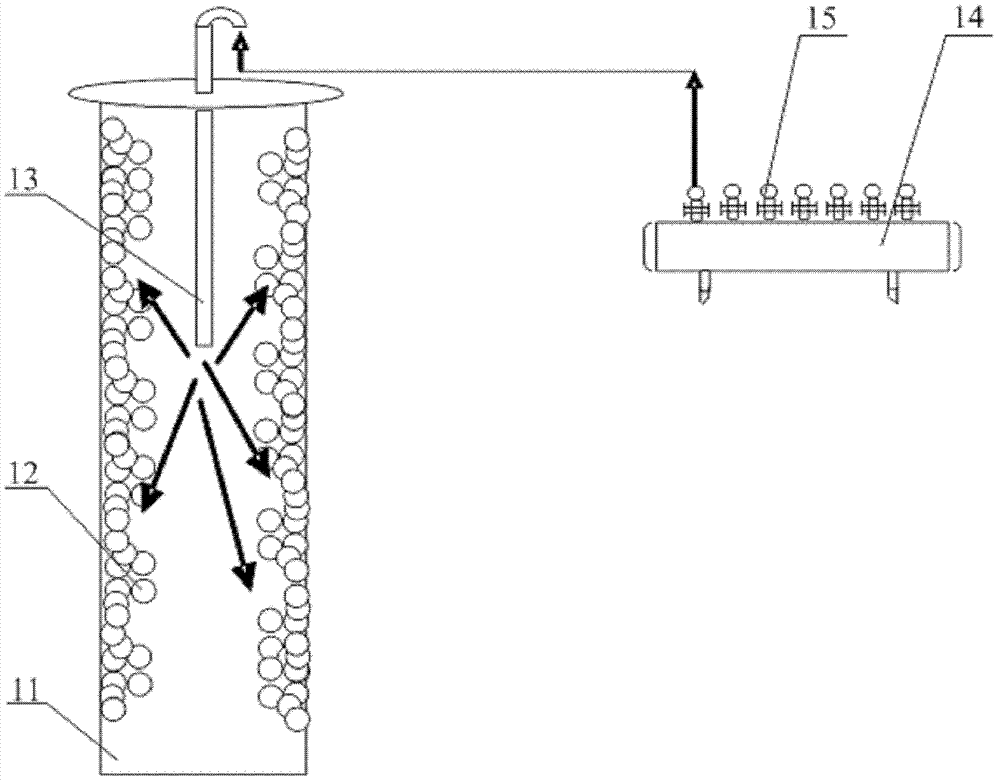

Embodiment Construction

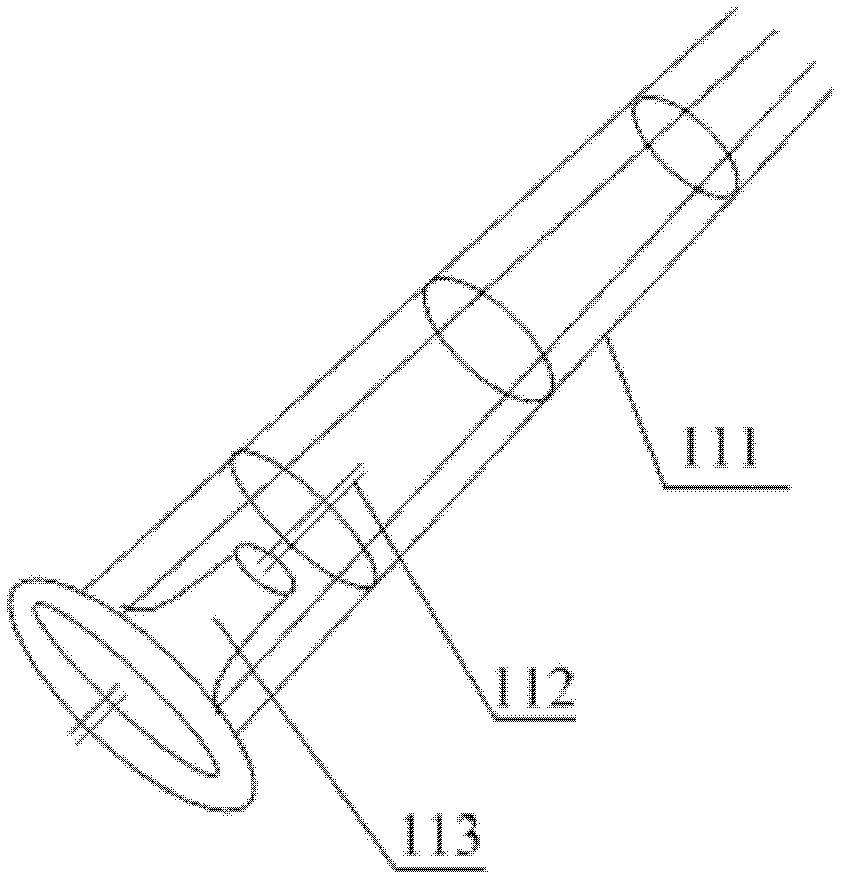

[0036] For the sake of reference and clarity, the technical terms appearing in the embodiments of the present invention are now explained as follows:

[0037] PVC dust bag: a dust bag made of PVC (Polyvinylchloride, polyvinyl chloride) material.

[0038] Cylinder poppet valve: a switch valve that uses a cylinder as the power source for opening and closing.

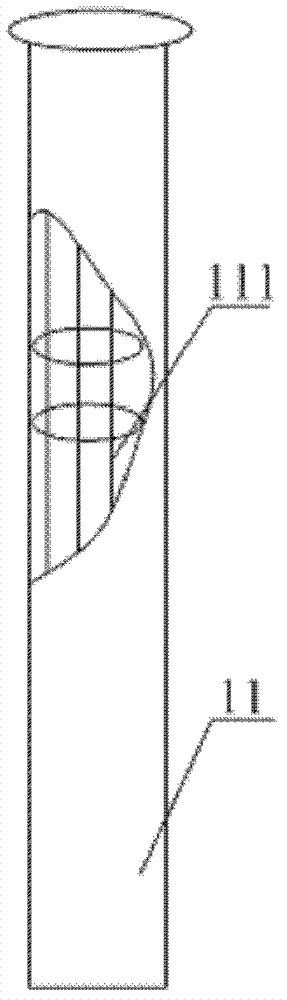

[0039] The invention provides a bag filter, which is improved on the basis of the existing bag filter, and alternately works through different dust removal areas in the box, thereby realizing the alternate work of the dust bags in the box. The sudden contraction or propping up of the dust removal bag during the alternate working process can shake off the dust on the dust removal bag and realize dust removal. The bag filter provided by the invention simplifies the existing bag filter and reduces the manufacturing cost of the bag filter.

[0040] The following will clearly and completely describe the technical solutions in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com