Preparation method for micro magnet-carried TiO2 catalyst

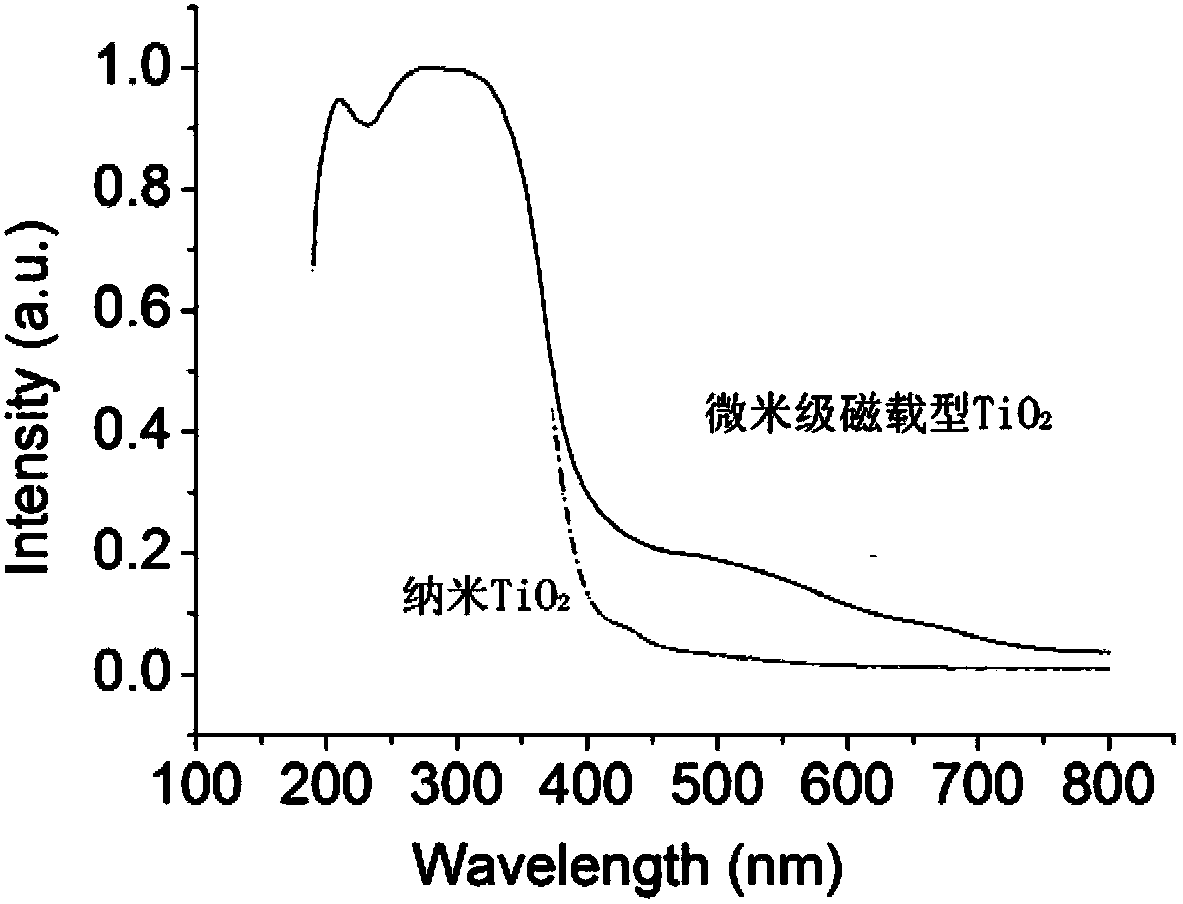

A micron-scale catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult to meet the requirements of photocatalytic degradation reactions, narrow excitation wavelength range, low sunlight response, etc., to achieve The effect of improving the utilization rate of sunlight, shortening the sol time, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

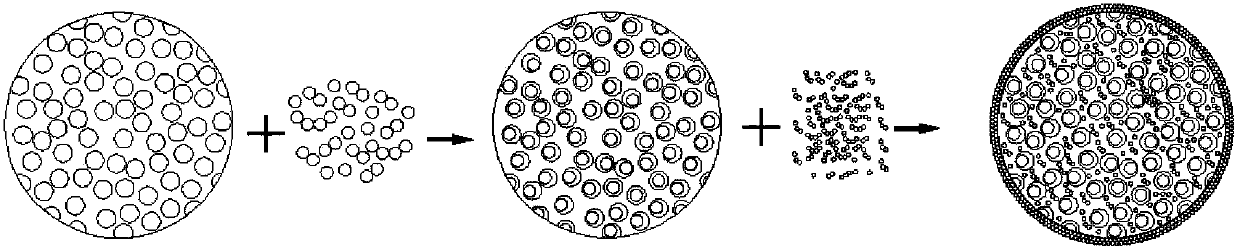

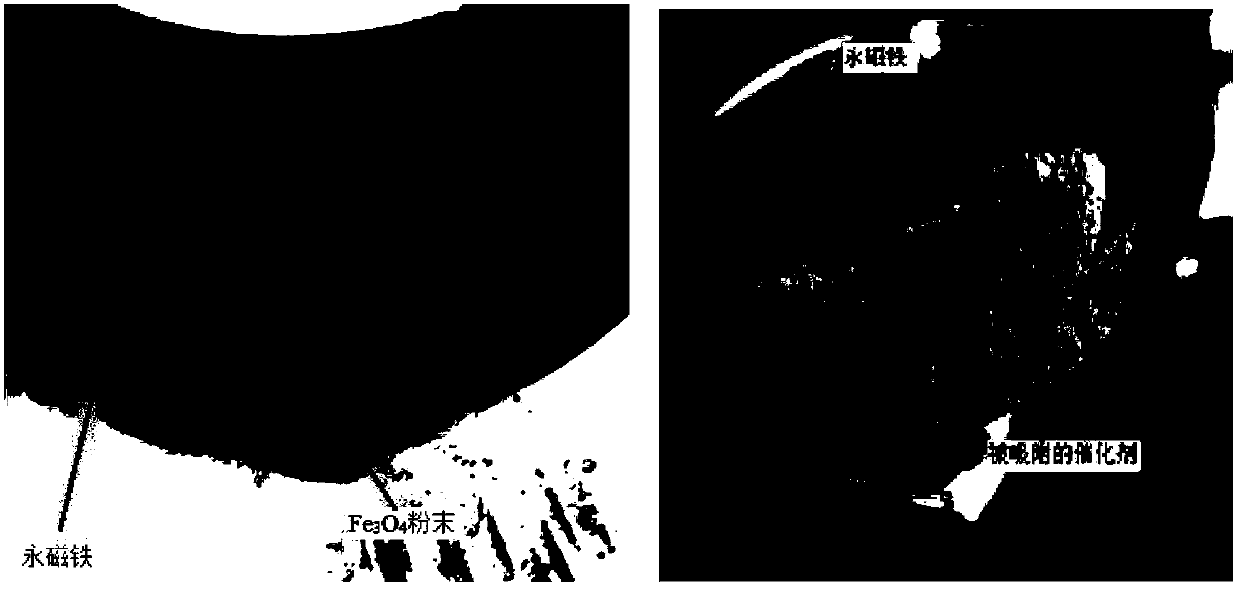

[0035] Example 1 Micron-scale magnetically supported TiO 2 Catalyst preparation

[0036] Process 1: Fe 3 o 4 Preparation of micron-sized magnetic cores with 85% loading

[0037] 37.5g FeSO 4 ·7H 2 O was dissolved in 500ml distilled water to prepare 0.27mol / L FeSO 4 Solution, sealed and preserved, prepared and used now; 32g Fe 2 (SO 4 ) 3 Dissolve in 500ml of distilled water to prepare 0.16mol / L Fe 2 (SO 4 ) 3 The solution is ready for immediate use; prepare a 2mol / L NaOH solution for later use. At a temperature of 15°C-35°C, mix 0.2g of activated MCM-41 mesoporous molecular sieve with 20ml of 0.27mol / L FeSO 4 Put the solution in a beaker, disperse it by ultrasonic for 5 minutes, and record it as component A; measure 50ml of 0.16mol / L Fe 2 (SO 4 ) 3 Solution, denoted as B component. Place component A in an ultrasonic disperser, turn on mechanical stirring and ultrasound, quickly add component B to component A and mix evenly to form component C; add 2 mol / L NaOH ...

Embodiment 2

[0041] Example 2 Micron-scale magnetically supported TiO 2 Catalyst preparation

[0042] Process 1: Fe 3 o 4 Preparation of micron-sized magnetic cores with 55% loading

[0043] 37.5g FeSO 4 ·7H 2 O was dissolved in 500ml distilled water to prepare 0.27mol / L FeSO 4 Solution, sealed and preserved, prepared and used now; 32g Fe 2 (SO 4 ) 3 Dissolve in 500ml of distilled water to prepare 0.16mol / L Fe 2 (SO 4 ) 3 The solution is ready for immediate use; prepare a 2mol / L NaOH solution for later use. At a temperature of 15°C-35°C, mix 1g of activated MCM-41 mesoporous molecular sieve with 20ml of 0.27mol / L FeSO 4 Put the solution in a beaker, disperse it by ultrasonic for 5 minutes, and record it as component A; measure 50ml of 0.16mol / L Fe 2 (SO 4 ) 3 Solution, denoted as B component. Place component A in an ultrasonic disperser, turn on mechanical stirring and ultrasound, quickly add component B to component A and mix evenly to form component C; add 2 mol / L NaOH so...

Embodiment 3

[0047] Example 3 Micron-scale magnetically supported TiO 2 Catalyst preparation

[0048] Process 1: Fe 3 o 4 Preparation of micron-sized magnetic cores with 20% loading

[0049] 37.5g FeSO 4 ·7H 2 O was dissolved in 500ml distilled water to prepare 0.27mol / L FeSO 4 Solution, sealed and preserved, prepared and used now; 32g Fe 2 (SO 4 ) 3 Dissolve in 500ml of distilled water to prepare 0.16mol / L Fe 2 (SO 4 ) 3 The solution is ready for immediate use; prepare a 2mol / L NaOH solution for later use. At a temperature of 15°C-35°C, mix 5g of activated MCM-41 mesoporous molecular sieve with 20ml of 0.27mol / L FeSO 4 Put the solution in a beaker, disperse it by ultrasonic for 5 minutes, and record it as component A; measure 50ml of 0.16mol / L Fe 2 (SO 4 ) 3 Solution, denoted as B component. Place component A in an ultrasonic disperser, turn on mechanical stirring and ultrasound, quickly add component B to component A and mix evenly to form component C; add 2 mol / L NaOH so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com