Efficient and energy-saving rubber dispersing and dissolving apparatus

A high-efficiency, energy-saving, dissolving device technology, applied in feeding device, control/regulating process, chemical/physical/physical-chemical stationary reactor, etc. Problems such as heating coils, lubricating oil failure, and unfavorable lubricating oil production efficiency can shorten the sol time, have a high degree of automation, and save the glue cutting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

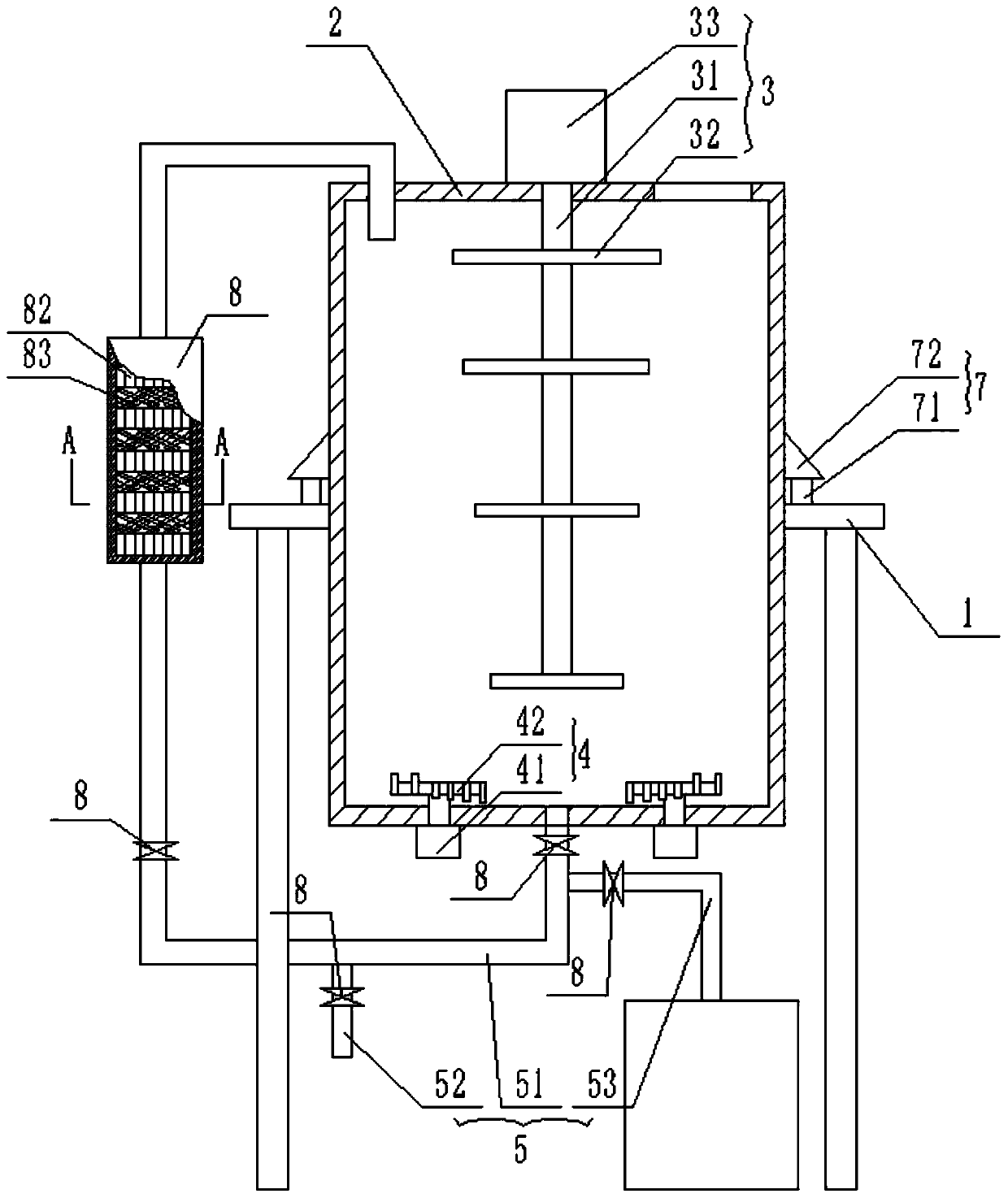

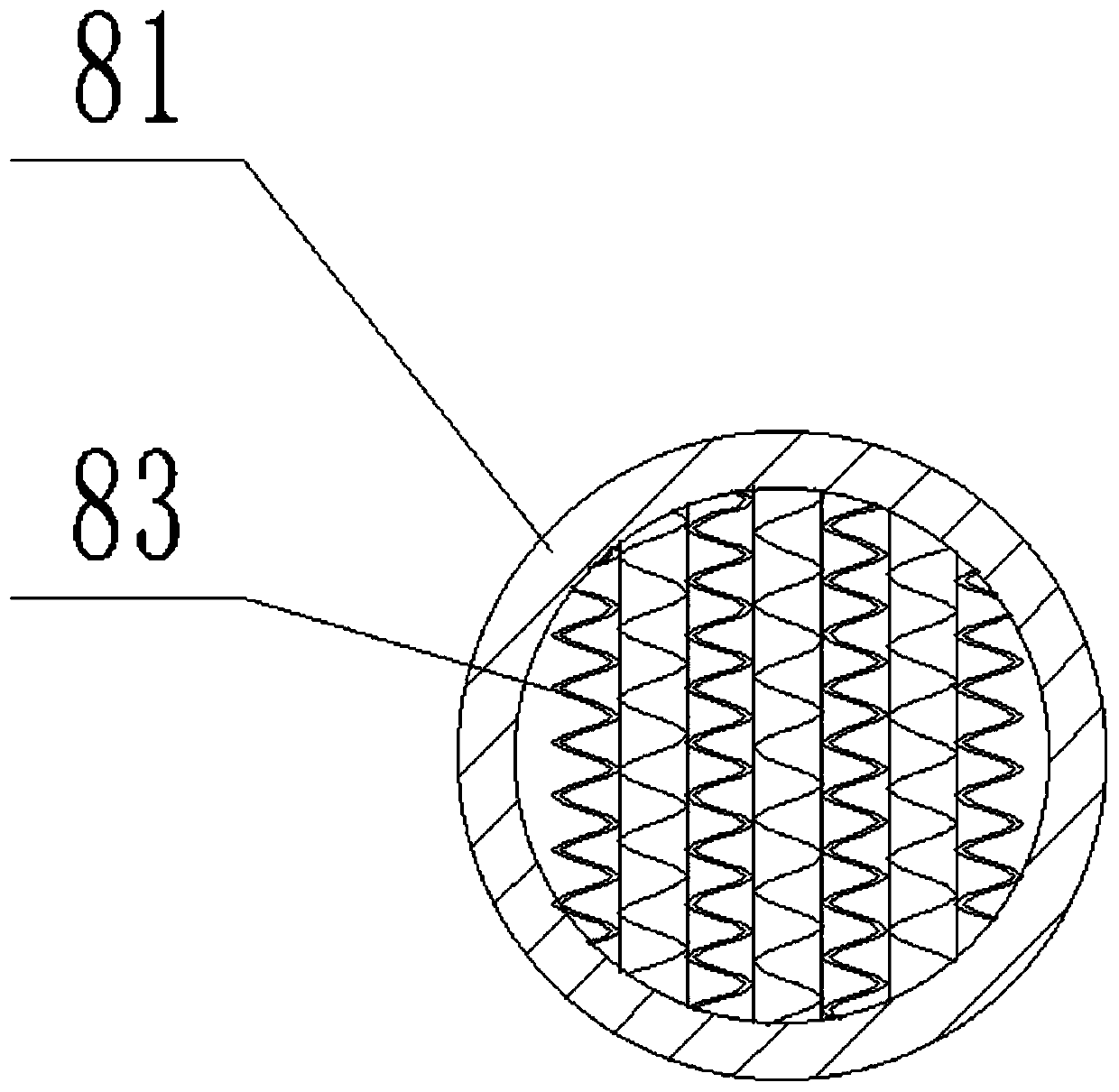

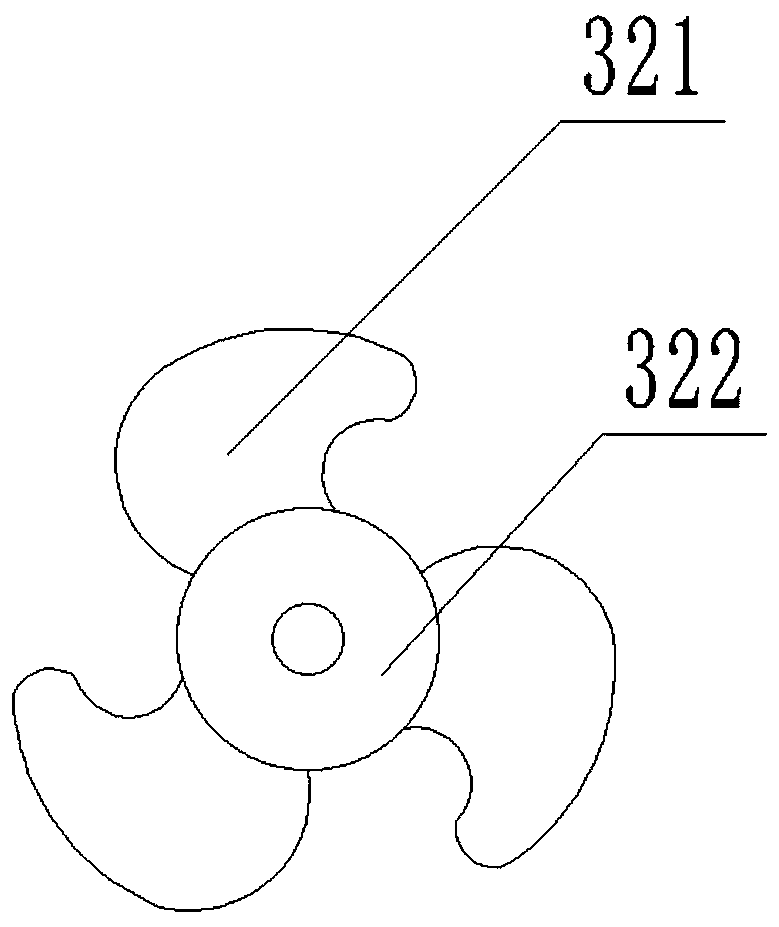

[0019] Such as Figure 1-3 As shown in , a high-efficiency and energy-saving rubber dispersing and dissolving device includes a support frame 1) and a reaction kettle 2 arranged on the support frame 1, a stirring shaft 31 vertically arranged in the reaction kettle 2, and the stirring shaft 31 is provided with a plurality of stirring paddles 32, and the stirring paddles 32 include a stirring plate 321 fixedly sleeved on the stirring shaft 31 and at least three stirring blades 322, and a plurality of the stirring blades 322 are evenly arranged on the stirring shaft 31. On the circumferential surface of the disc 321, the size of the plurality of stirring paddles 32 decreases sequentially from top to bottom, the upper end of the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com