Method for preparing micron-sized TiO2/AC catalyst

A micron-scale catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult to meet the requirements of photocatalytic degradation reaction, difficult to separate particles, low quantum yield, etc. Achieve the effects of delaying hydrolysis-polycondensation reaction, simplifying the preparation process, and high load firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

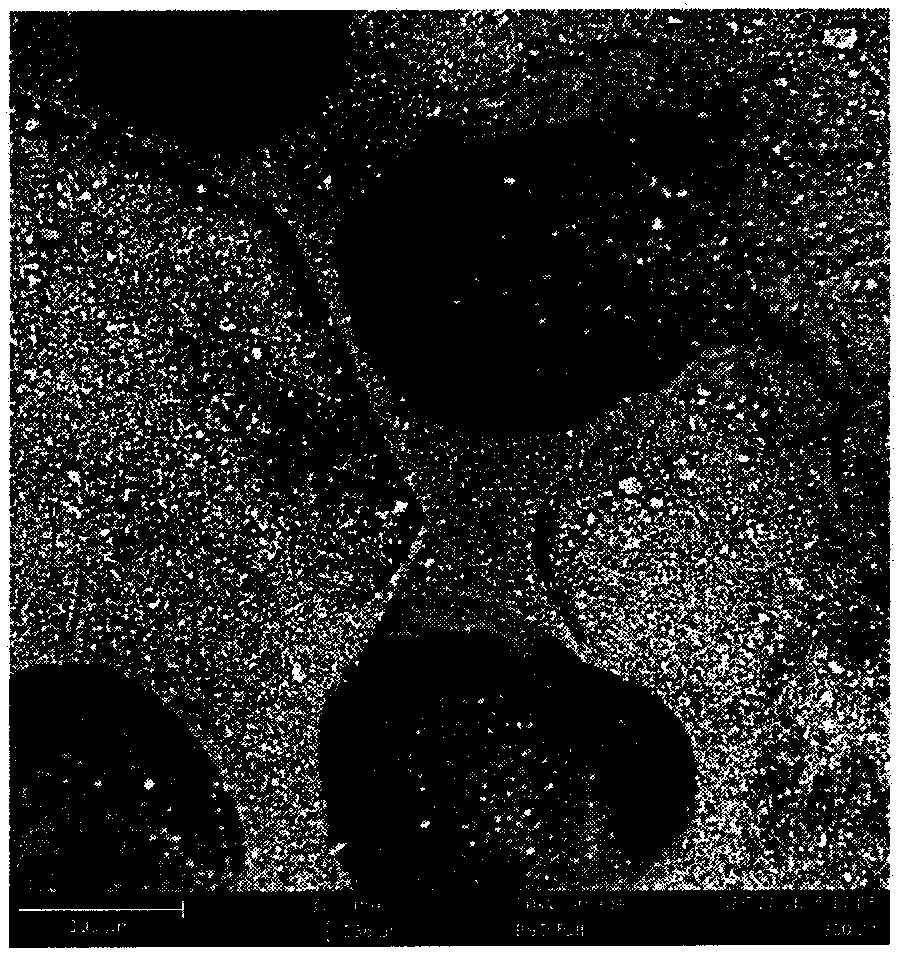

[0019] Such as figure 1 Said, the micron TiO of the present invention 2 The preparation method of catalyst comprises the following steps:

[0020] (1) Pretreatment of activated carbon

[0021] Take a certain amount of granular activated carbon and put it into 80°C pure water, stir and heat it for 30min, after filtering, put it into 30% nitric acid solution, mix it well for 30min, let it stand for 24h, filter and wash it with pure water until it becomes neutral, and bake it at 80°C Dry. After the activated carbon is cooled, it is pulverized with a sample preparation pulverizer for 2 minutes, ball milled at a ball milling speed of 270 r / min for 135 minutes, and placed in a desiccator for later use.

[0022] (2) Micron TiO 2 / AC catalyst preparation process

[0023] Preparation raw materials: activated carbon, butyl phthalate, absolute ethanol, glacial acetic acid, hydrochloric acid, pure water

[0024] Fully mix 10ml of butyl phthalate and 10ml of absolute ethanol in a sep...

Embodiment 1

[0027] Example 1 The calcination temperature is 300°C Micron TiO 2 / AC catalyst preparation.

[0028] Dissolve 10 mL of tetrabutyl titanate in 10 mL of absolute ethanol, stir for 10 minutes, and record it as liquid A; dissolve 1.5 mL of pure water, 1 mL of glacial acetic acid, and 1 mL of 0.1 mol / L hydrochloric acid-ethanol mixture in 6.5 mL of absolute ethanol , stirred for 10 min, and recorded as liquid B; poured 5.48 g of ball-milled activated carbon into 20 mL of 0.1 mol / L hydrochloric acid ethanol, stirred for 30 min, and recorded as liquid C. Place liquid C on a magnetic stirrer and stir vigorously. At the same time, liquid A and liquid B are added dropwise to liquid C at a speed of 60 drops / min and 15 drops / min respectively. After adding liquid A for 2 minutes, add liquid B dropwise. During the dropwise addition, the butyl phthalate hydrolysis system was ultrasonically treated to form a sol. Continue to stir for 2 hours after the dropwise addition, and age for 24 hour...

Embodiment 2

[0029] Example 2 The calcination temperature is 400°C Micron TiO 2 / AC catalyst preparation.

[0030] Dissolve 10 mL of tetrabutyl titanate in 10 mL of absolute ethanol, stir for 10 minutes, and record it as liquid A; dissolve 1.5 mL of pure water, 1 mL of glacial acetic acid, and 1 mL of 0.1 mol / L hydrochloric acid-ethanol mixture in 6.5 mL of absolute ethanol , stirred for 10 min, and recorded as liquid B; poured 5.48 g of ball-milled activated carbon into 20 mL of 0.1 mol / L hydrochloric acid ethanol, stirred for 30 min, and recorded as liquid C. Place liquid C on a magnetic stirrer and stir vigorously. At the same time, liquid A and liquid B are added dropwise to liquid C at a speed of 60 drops / min and 15 drops / min respectively. After adding liquid A for 2 minutes, add liquid B dropwise. During the dropwise addition, the butyl phthalate hydrolysis system was ultrasonically treated to form a sol. Continue to stir for 2 hours after the dropwise addition, and age for 24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com