Preparation method of micron-order load type TiO2 catalyst

A micron-scale, supported technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult to meet the requirements of photocatalytic degradation reactions, difficult to separate particles, low quantum yield, etc., to achieve The effects of delaying the hydrolysis-polycondensation reaction, simplifying the preparation process, and improving the firmness of the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

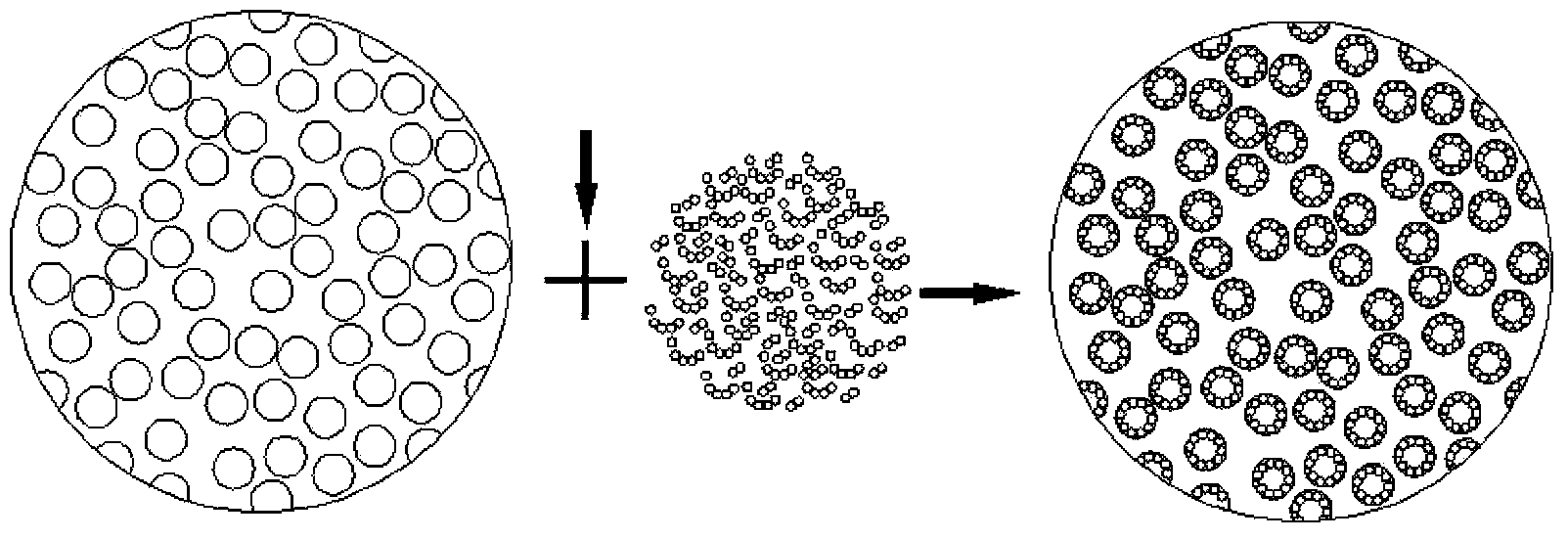

[0025] Such as figure 1 As shown, the micron-scale supported TiO of the present invention 2 The preparation method of catalyst comprises the following steps:

[0026] (1) Activation pretreatment of the carrier

[0027] Using micron-sized MCM-41 mesoporous molecular sieve as micron-sized supported TiO 2 Catalyst carrier, the MCM-41 mesoporous molecular sieve is placed in a muffle furnace, and the heat treatment and activation of the MCM-41 mesoporous molecular sieve is carried out by using a heat treatment crystallization forming step temperature rise and heat preservation method. The activation step is: heating up to within 1h-2h 200°C-250°C, constant temperature for 1h-2h; then heat up to 350°C-400°C within 1h-2h, constant temperature for 1h-2h; finally heat up to 550°C-600°C within 1h-2h, constant temperature for 4h-6h ;

[0028] (2) Preparation of butyl titanate hydrolysis buffer

[0029] Add 8.52 mL of concentrated hydrochloric acid with a mass fraction of 36% to 38% ...

Embodiment 1

[0037] Example 1 Loading capacity 20% micron-sized loaded TiO 2 Catalyst preparation

[0038] Mix 10mL butyl titanate and 10mL absolute ethanol to form A solution and place it in a pear-shaped separating funnel, take 2.1ml distilled water and 5ml hydrolysis buffer and mix thoroughly to form C component and place it in a pear-shaped separating funnel , then weigh 9.40g of activated MCM-41 molecular sieve and 100ml of butyl titanate hydrolysis buffer, mix them in a beaker, disperse ultrasonically for 20min to form component B, put it on a magnetic stirrer, start stirring, and add dropwise to component B For component A, add component C dropwise after 2 minutes. The dropping speed of component A is about 60-90 drops / min. At the initial stage of dropping, first add component A dropwise, and after 2 minutes, start to add component C dropwise, and the dropping rate of component C is 20-30 drops / min. Use ultrasonic waves to treat the butyl titanate hydrolysis system intermittently...

Embodiment 2

[0039] Example 2 Loading capacity 30% micron-sized loaded TiO 2 Catalyst preparation

[0040] Mix 10mL butyl titanate and 10mL absolute ethanol to form A solution and place it in a pear-shaped separating funnel, take 2.1ml distilled water and 5ml hydrolysis buffer and mix thoroughly to form C component and place it in a pear-shaped separating funnel , then weigh 5.48g of activated MCM-41 molecular sieves and 50ml of butyl titanate hydrolysis buffer, mix them in a beaker, and disperse ultrasonically for 15 minutes to form component B. Put it on a magnetic stirrer, start stirring, and add dropwise to component B For component A, add component C dropwise after 2 minutes. The dropping speed of component A is about 60-90 drops / min. At the initial stage of dropping, first add component A dropwise, and after 2 minutes, start to add component C dropwise, and the dropping rate of component C is 20-30 drops / min. Use ultrasonic waves to treat the butyl titanate hydrolysis system inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com