Method for milling hardened gear surface of spiral bevel gear

A technology of milling and bevel gear, applied in the field of gear processing, can solve the problems of high processing cost and low efficiency, and achieve the effect of changing the high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

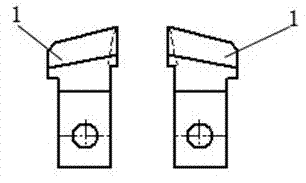

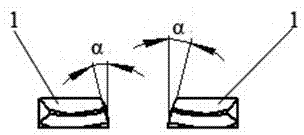

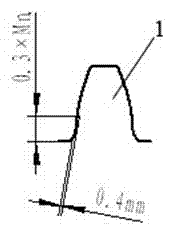

[0018] see figure 1 , figure 2 , image 3 and Figure 4 , described a kind of helical bevel gear hard tooth surface milling method, its steps are as follows:

[0019] The first step is to process the spiral bevel gear blank 2, which is carried out on the spiral bevel gear milling machine. The spiral bevel gear blank will be made with 20CrMnTi or 20CrMnMo, the meshing coloring and the length direction of the meshing surface should be controlled to account for 50% ± 10%. The surface height direction accounts for 70% ± 10%, and the tooth thickness reserves 0.2 ~ 0.3mm allowance;

[0020] The second step is to increase the angle of relief on the tip of the milling cutter head, and it is carried out on the spiral bevel gear milling machine to process the effective angle of relief for the tooth root of the spiral bevel gear blank (see image 3 );

[0021] The third st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com