Low-eradiation coated glass available for heat treatment and sandwich glass products thereof

A low-emissivity coating and glass technology, which is applied in the field of single silver-coated laminated glass, low-emission coated glass and its laminated glass products, can solve problems such as not suitable for oxygen atom diffusion, achieve qualified thermal stability, improve mechanical stability, The effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0040] Sodium calcium silicate float white glass or green glass with a thickness of 2.1 mm is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for deposition, and the background vacuum is high. at 9×10 -4 Pa. According to the different film structures shown in Table 2, they were sequentially deposited on the glass. Si 3 N 4 Using SiAl alloy target in Ar / N 2 Intermediate frequency reactive sputtering deposition in a mixed atmosphere with a flow ratio of 1 / 1, ZnSnOx using Zn50Sn50 alloy target in Ar / O 2 Intermediate frequency reactive sputtering in a mixed atmosphere with a flow ratio of 1 / 1, ZnO is a Zn98Al2 alloy target in Ar / O 2 Intermediate frequency reactive sputtering deposition in a mixed atmosphere with a flow ratio of 2 / 3, Ag and Ti were deposited by DC sputtering in an Ar atmosphere, ZrO 2 Using Zr metal target in Ar / O 2 Intermediate frequency reactive sputtering deposition in a mixed atmosphere wi...

Embodiment 6~9

[0052] Sodium calcium silicate float white glass or green glass with a thickness of 2.1 mm is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for deposition, and the background vacuum is high. at 9×10 -4 Pa. According to the different film structures shown in Table 4, deposit sequentially on the glass: ZnSnOx, ZnO, Ag, Ti, ZnO, ZrO 2 and SiO 2 layer. Among them, ZnSnOx adopts Zn50Sn50 alloy target in Ar / O 2 Intermediate frequency reactive sputtering in a mixed atmosphere with a flow ratio of 1 / 1, ZnO is a Zn98Al2 alloy target in Ar / O 2 Intermediate frequency reactive sputtering deposition in a mixed atmosphere with a flow ratio of 2 / 3, Ag and Ti were deposited by DC sputtering in an Ar atmosphere, ZrO 2 Using Zr metal target in Ar / O 2 Intermediate Frequency Reactive Sputtering Deposition in a Mixed Atmosphere with a Flow Ratio of 3 / 1, SiO 2 Using SiAl alloy target in Ar / O 2 Intermediate frequency sputter...

Embodiment 10~12

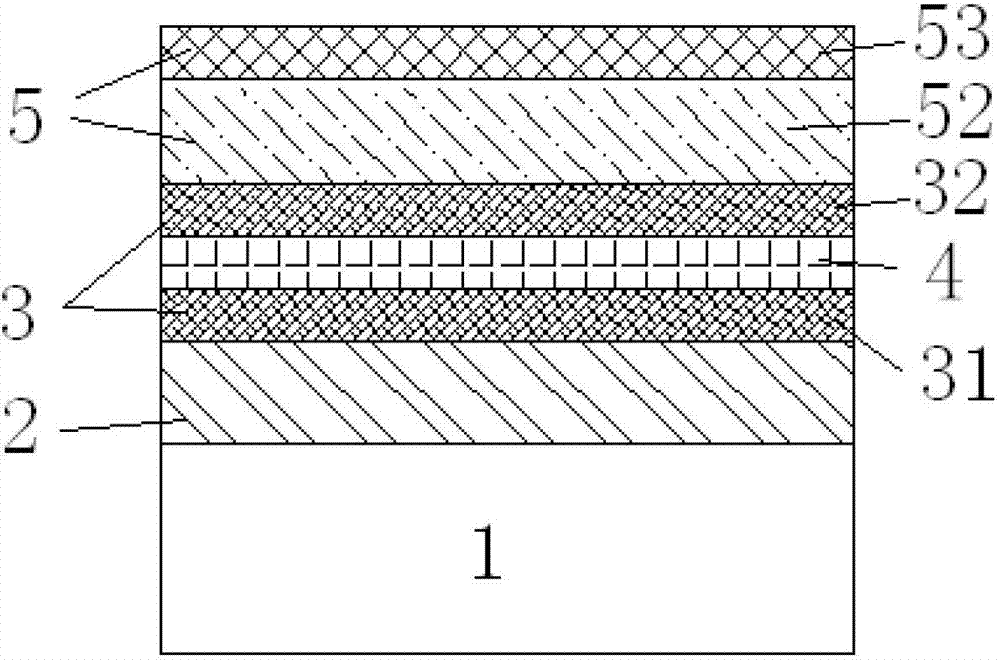

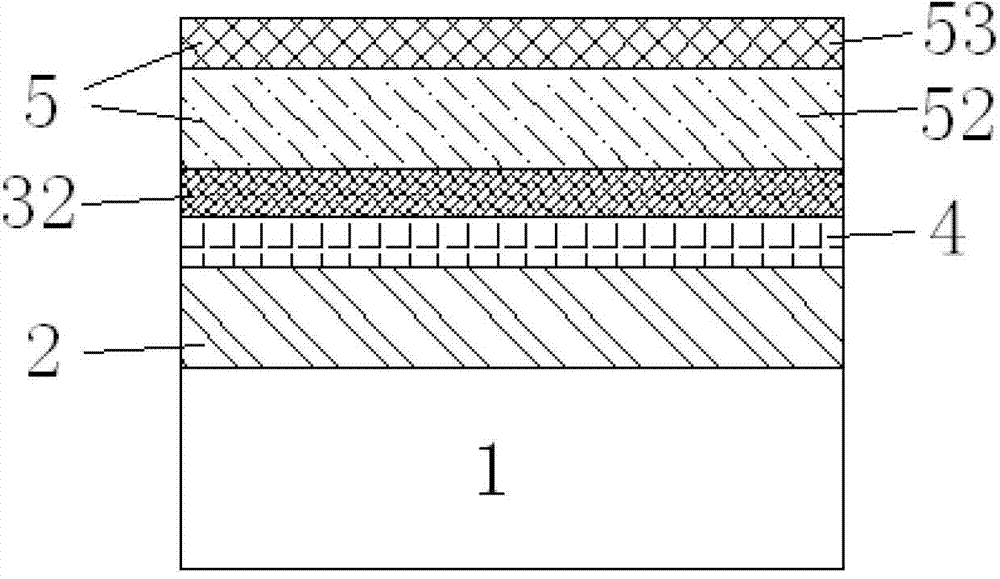

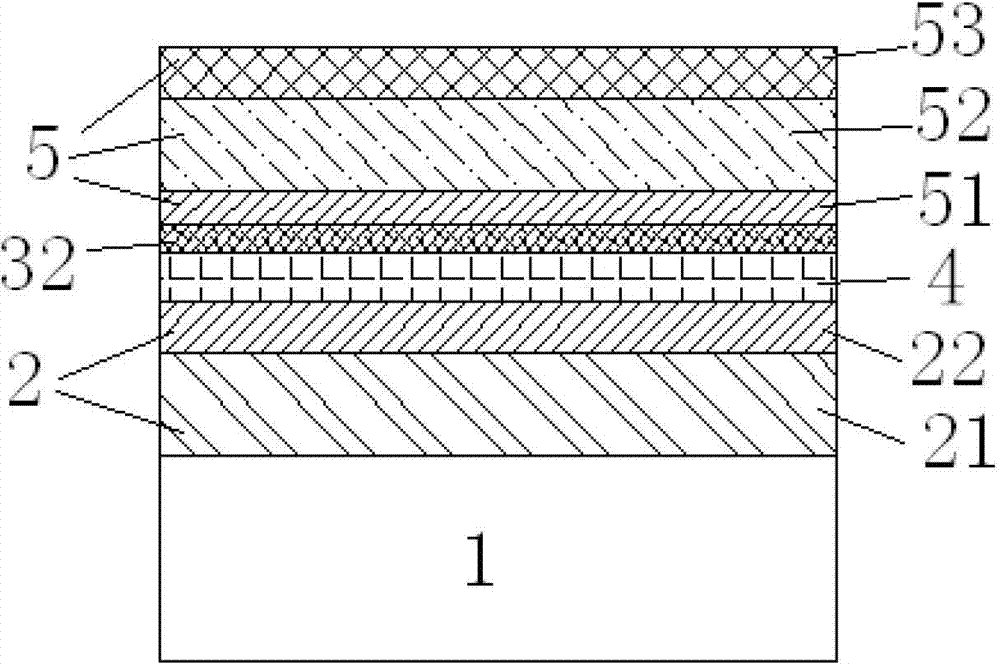

[0058] Sodium calcium silicate float white glass or green glass with a thickness of 2.1 mm is used as the coating substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for coating deposition. The background vacuum degrees higher than 9×10 -4 Pa, as shown in table 5, deposited film layer structure is embodiment 3 in table 2, then will be deposited with the white glass of embodiment 3 film layer structure and the white glass of 2.1 millimeters of thickness or green glass matching sheet baking It is bent and formed, and a piece of colorless PVB film with a thickness of 0.76 mm is sandwiched in the middle, and the sheets are combined in an autoclave under high pressure to finally make a laminated glass product. The structural diagram is as follows Figure 4 and Figure 5 shown.

[0059] Table 5 Embodiment 10~12 structure and its main technical indicators

[0060]

[0061]

[0062] Wherein, whether the coated glass is used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com