Blue-phase liquid crystal composite and manufacturing method of blue-phase liquid crystal composite

A blue-phase liquid crystal and composite material technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of complex process, difficult production, narrow viewing angle, etc., and achieve the effect of fast electric field response, good electro-optical performance, and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

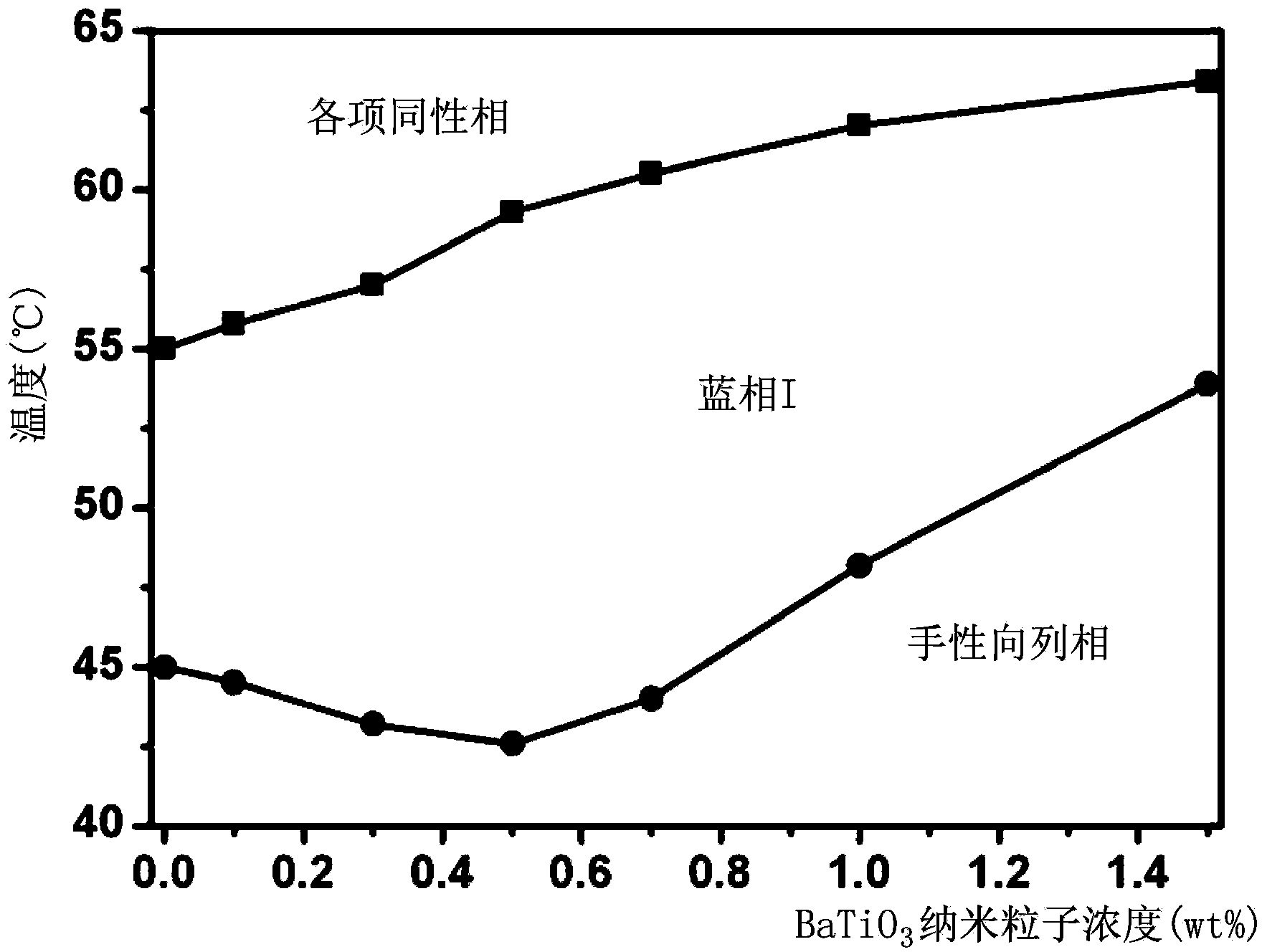

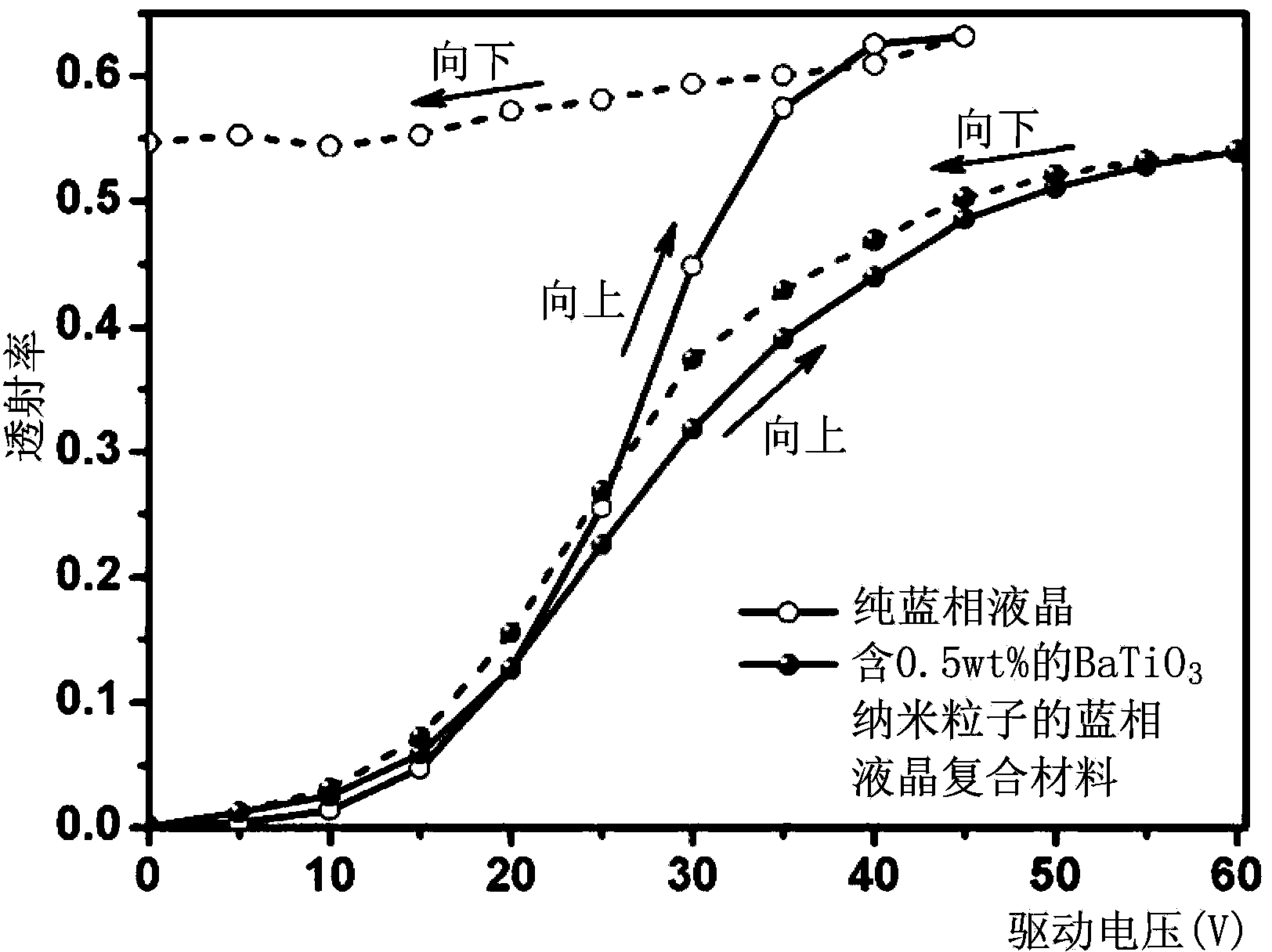

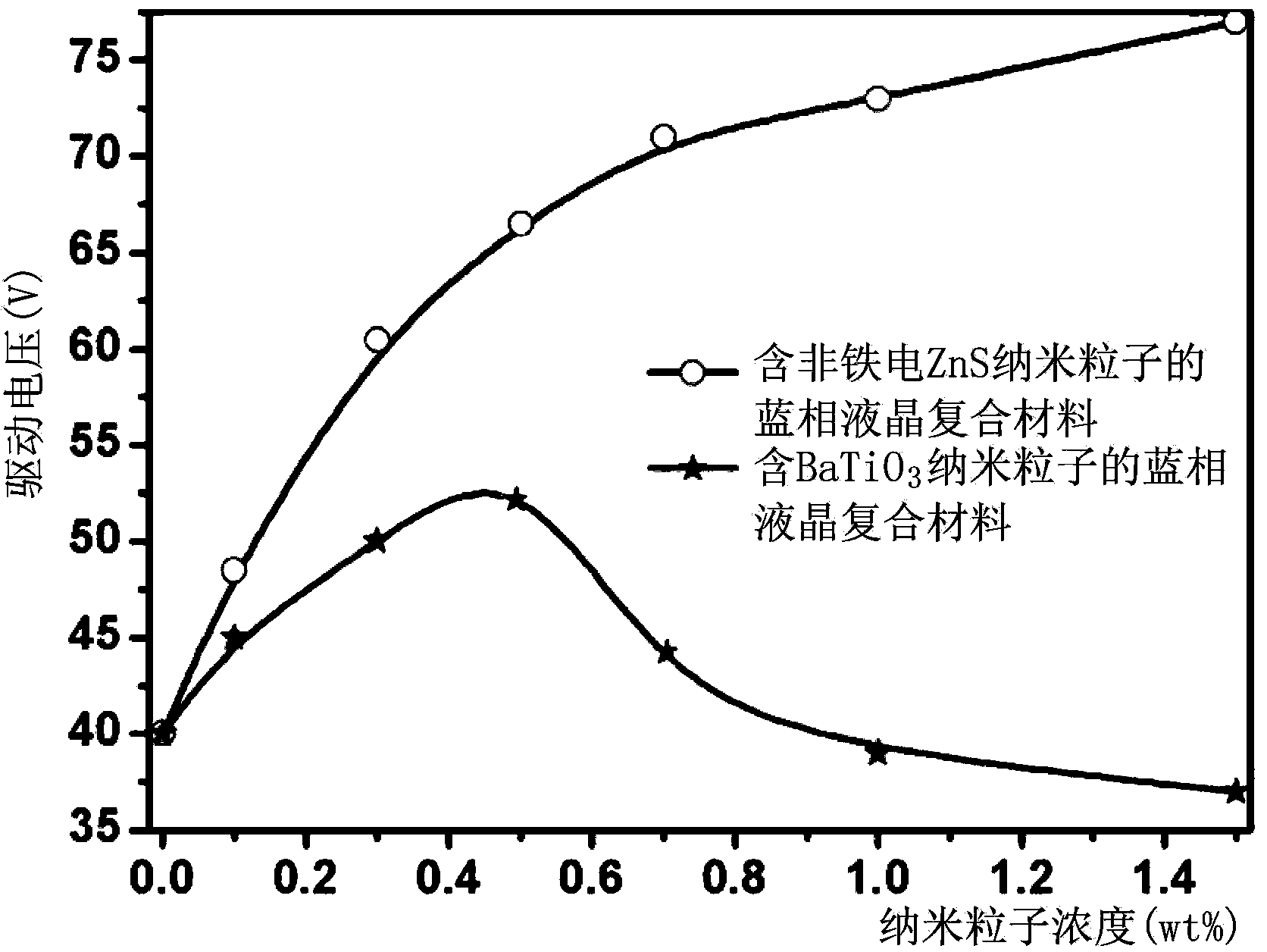

[0027] This embodiment includes ferroelectric barium titanate (BaTiO 3 ) blue phase liquid crystal composite material of nanoparticles and its preparation method are described.

[0028] In this example, first, the ferroelectric BaTiO 3 The powder (for example, the diameter of the ground powder is about 1 micron) is mixed with oleic acid (surfactant) and heptane (carrier liquid) at a weight ratio of 1:2:10. After ultrasonic dispersion, the planetary high-energy ball mill for 15 hours to produce BaTiO 3 nanoparticle dispersion. Second, the ball-milled BaTiO 3 Transfer the nanoparticle dispersion to a beaker and let it stand for a few days (for example, 3 days), and then use a screen filter to remove BaTiO with a particle size larger than 30nm. 3 Nanoparticles, thereby making BaTiO with a specific particle size (average particle size) of 30nm 3 nanoparticle dispersion.

[0029] Next, the obtained BaTiO containing a specific particle size of 30nm 3 The nanoparticle dispersi...

Embodiment 2

[0039] This embodiment includes ferroelectric sulfur tin phosphide (Sn 2 P 2 S 6 ) blue phase liquid crystal composite material of nanoparticles and its preparation method are described.

[0040] In this embodiment, first, the ferroelectric Sn 2 P 2 S 6 The powder (for example, the diameter of the ground powder is about 1 micron) is mixed with oleic acid (surfactant) and heptane (carrier liquid) at a weight ratio of 1:2:10. After ultrasonic dispersion, the planetary high-energy ball mill for 50 hours to produce Sn 2 P 2 S 6 nanoparticle dispersion. Second, the Sn after ball milling 2 P 2 S 6 The nanoparticle dispersion is transferred to a beaker and left to stand for several days (for example, 3 days), and then filtered through a screen window to remove Sn with a particle size greater than 9nm. 2 P 2 S 6 Nanoparticles, thereby making Sn with a specific particle size (average particle size) of 9nm 2 P 2 S 6 nanoparticle dispersion.

[0041] Next, the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com