Preparation method for diphasic nanometer particle dispersion strengthening copper matrix composite material

A dispersion-strengthened copper and nanoparticle technology, applied in the field of copper-based composite materials, can solve the problems of insufficient dispersion distribution, comprehensive performance of composite materials, complex preparation process, and high input cost, and achieve excellent high-temperature softening resistance. The effect of improving comprehensive performance and refining matrix grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

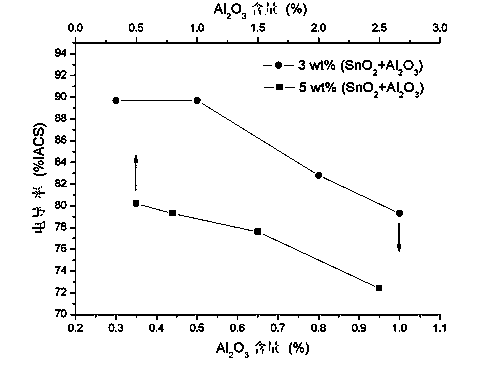

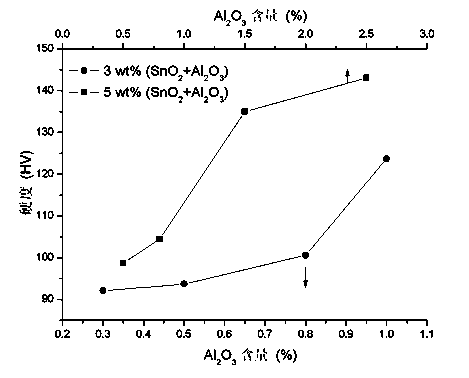

Image

Examples

Embodiment 1

[0025] The first step is to prepare Ti 4+ Ion-doped Sn(OH) 4 dry powder and Al(OH) 3 dry powder

[0026] The required amount of SnCl 4 ·5H 2 O powder was dissolved in ethanol / distilled water mixed solvent with a volume ratio of 3:2, prepared into a solution with a concentration of 0.08mol / L, and placed on a magnetic stirrer platform to stir to make it uniform, and then according to the ion molar ratio Ti 4+ :(Sn 4+ +Ti 4+ ) = 5:100 to take the required amount of TiCl 4 Add the SnCl prepared above 4 ·5H 2 O solution, while adding the amount of Sn(OH) 4 2% of the mass of the dispersant polyethylene glycol-20000, stir evenly, heat up to 60 ° C, and then keep stirring for 30 minutes to obtain a clear mixed solution, and then titrate the volume percentage concentration in the solution under the stirring of a magnetic stirrer 35% ammonia water to PH value of 8 to generate Ti 4+ Ion-doped Sn(OH) 4 Colloidal precipitate, after standing for 12 hours, pour out the supernatan...

Embodiment 2

[0036] The first step is to prepare Ti 4+ Ion-doped Sn(OH) 4 dry powder and Al(OH) 3 dry powder

[0037] The required amount of SnCl 4 ·5H 2 O powder was dissolved in ethanol / distilled water mixed solvent with a volume ratio of 3:2, prepared into a solution with a concentration of 0.10 mol / L, and placed on a magnetic stirrer platform to stir to make it uniform, and then according to the ion molar ratio Ti 4+ :(Sn 4+ +Ti 4+ ) = 5:100 to take the required amount of TiCl 4 Add the SnCl prepared above 4 ·5H 2 O solution, while adding the amount of Sn(OH) 4 2% of the mass of the dispersant polyethylene glycol-20000, stir evenly, after the temperature rises to 65°C, keep warm and stir for 30 minutes to obtain a clear mixed solution, and then titrate the volume percentage concentration in the solution under the stirring of a magnetic stirrer 35% ammonia water to PH value of 9 to generate Ti 4+ Ion-doped Sn(OH) 4Colloidal precipitation, after standing still for 13 hours, p...

Embodiment 3

[0046] The first step is to prepare Ti 4+ Ion-doped Sn(OH) 4 dry powder and Al(OH) 3 dry powder

[0047] The required amount of SnCl 4 ·5H 2 O powder was dissolved in ethanol / distilled water mixed solvent with a volume ratio of 3:2, prepared into a solution with a concentration of 0.12 mol / L, and placed on a magnetic stirrer platform to stir to make it uniform, and then according to the ion molar ratio Ti 4+ :(Sn 4+ +Ti 4+ ) = 5:100 to take the required amount of TiCl 4 Add the SnCl prepared above 4 ·5H 2 O solution, while adding the amount of Sn(OH) 4 2% by mass of dispersant polyethylene glycol-20000, stir evenly, heat up to 70°C, then heat and stir for 30 minutes to obtain a clear mixed solution, and then titrate the volume percentage concentration in the solution under the stirring of a magnetic stirrer 35% ammonia water to PH value of 8 to generate Ti 4+ Ion-doped Sn(OH) 4 Colloidal precipitation, after standing still for 14 hours, pour out the supernatant, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com