Surface modification method for dual polar plates of proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cell parts, battery electrodes, circuits, etc., can solve the process of corrosion resistance and electrical conductivity hindering commercial production, thermal deformation of stainless steel bipolar plates, TiN coating Coating defects and other problems, to promote promotion and application, improve corrosion resistance, reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

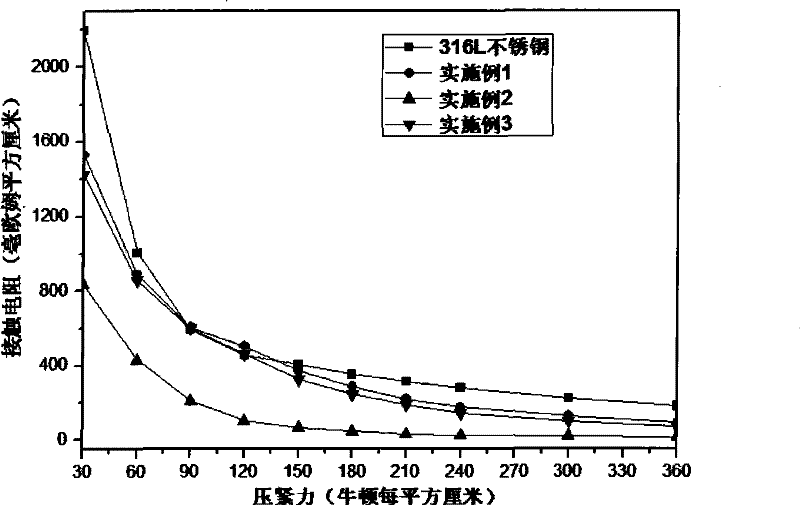

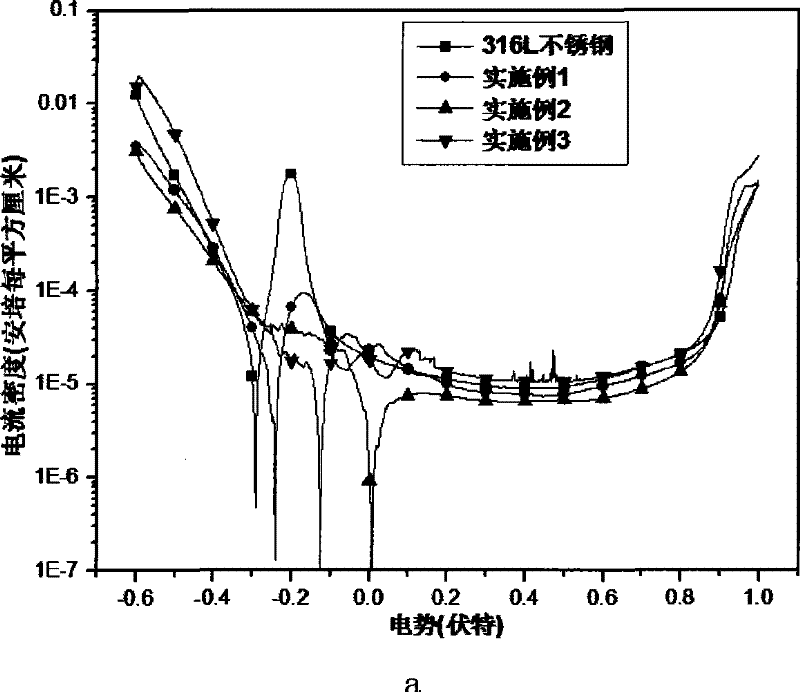

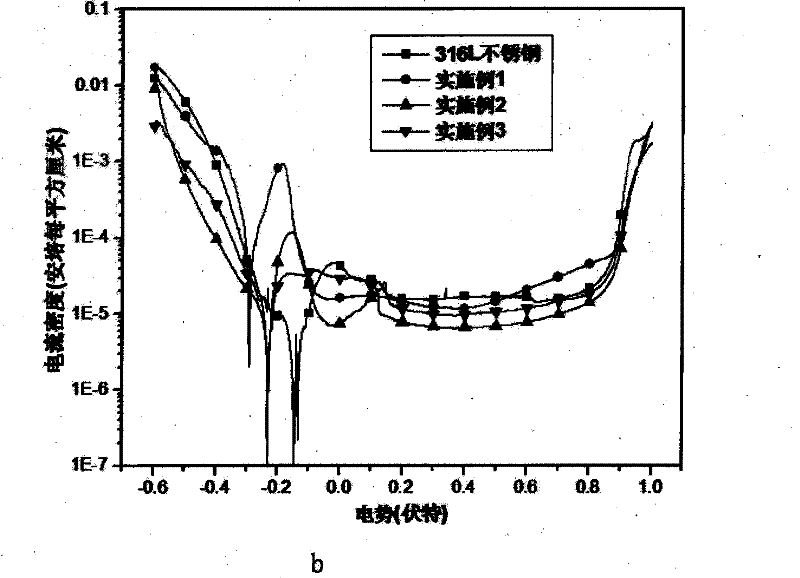

[0023] Take 316L stainless steel through conventional grinding, water washing, alcohol washing, degreasing and drying, then put it into a multi-functional ion coating machine for vacuuming, and wait until the vacuum degree reaches 1×10 -4 Pa~1×10 -2 Ion implantation starts at Pa, the accelerating voltage is 10-60KeV, the beam intensity is 1-10uA, and the surface temperature of the bipolar plate is 100-200°C. The specific process parameters are shown in the table below:

[0024] Table 1 Stainless steel bipolar plates treated under different process conditions

[0025] Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com