Manufacturing method of Fe-Ni-Cr alloy fuel cell bi-polar plate

A fe-ni-cr, 1.fe-ni-cr technology is applied in the field of making Fe-Ni-Cr alloy fuel cell bipolar plates, which can solve the problem that the iron-based surface cannot fully meet the requirements of fuel cell operation, and the coating The problems of immature layer technology and unfavorable processing can achieve the effect of reducing corrosion current density and surface contact resistance, enhancing surface conductivity and corrosion resistance, and improving conductivity and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

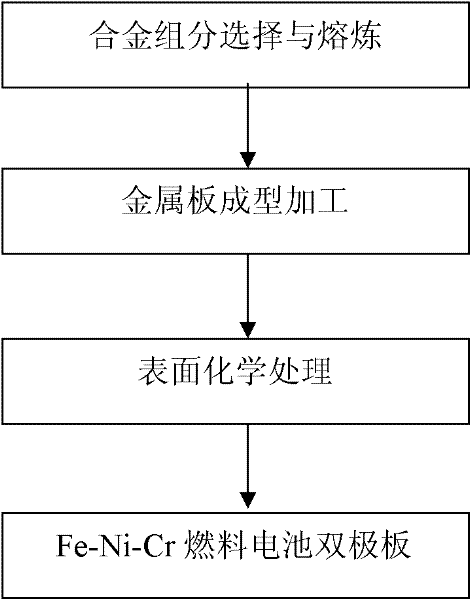

[0029] like figure 1 Shown, the manufacture method of Fe-Ni-Cr alloy fuel cell bipolar plate, it comprises the steps:

[0030] (1) Selection and smelting of alloy components: According to the ingredients of 38% Fe (atomic percentage), 33% Ni (atomic percentage), and 29% Cr (atomic percentage), Fe is obtained by vacuum induction melting 38 Ni 33 Cr 29 Alloy (vacuum induction melting is a conventional method);

[0031] (2) metal plate forming processing: the above alloy is processed into a metal plate with a flow field according to a conventional method;

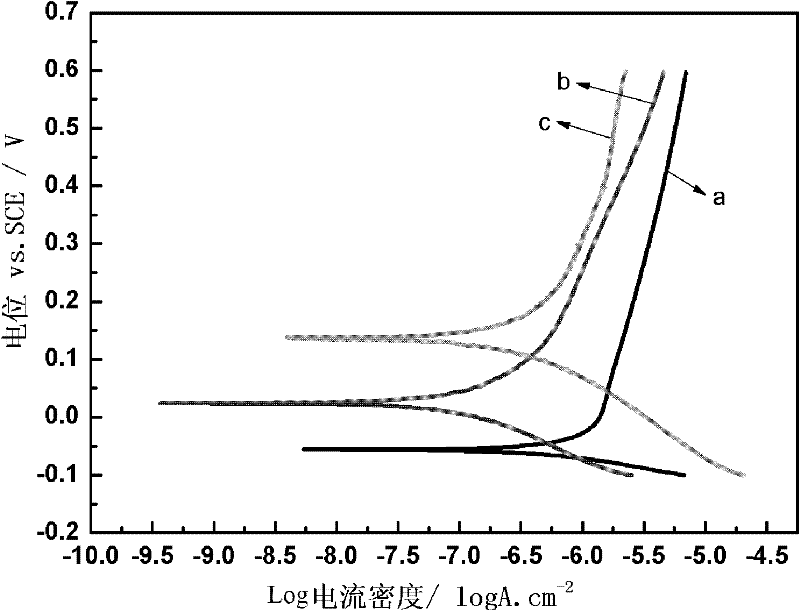

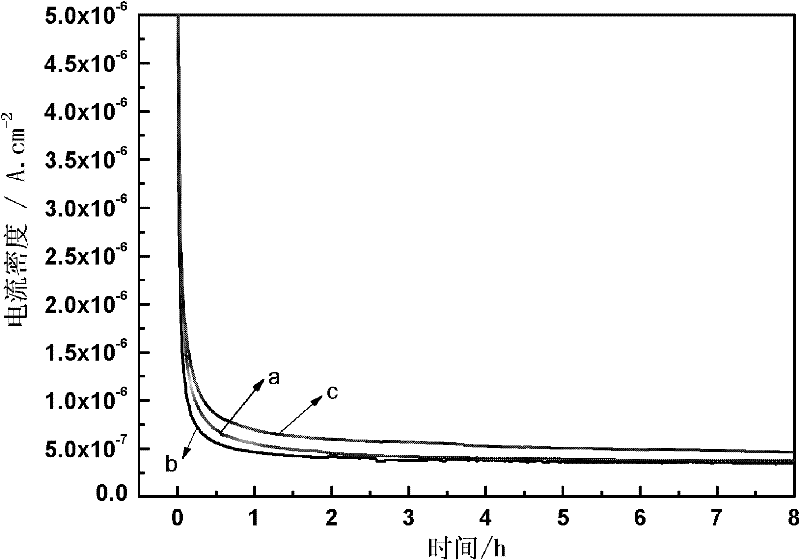

[0032] (3) Surface chemical treatment: place the metal plate with a flow field in a HF solution with a volume concentration of 47%, soak it at 25°C for 8 minutes, take it out, wash it with water, dry it, and put it in H 2 SO 4 and HF mixed aqueous solution, H 2 SO 4The concentration of the substance is 0.5mol / L, the concentration of the substance of HF is 5ppm, with the metal plate as the working electrode, Pt as the co...

Embodiment 2

[0038] like figure 1 Shown, the manufacture method of Fe-Ni-Cr alloy fuel cell bipolar plate, it comprises the steps:

[0039] (1) Selection and smelting of alloy components: According to the ingredients of 37% Fe (atomic percentage), 34% Ni (atomic percentage), and 29% Cr (atomic percentage), Fe is obtained by vacuum induction melting 37 Ni 34 Cr 29 alloy;

[0040] (2) metal plate forming processing: the above alloy is processed into a metal plate with a flow field according to a conventional method;

[0041] (3) Surface chemical treatment: place the metal plate with a flow field in an HF aqueous solution with a volume concentration of 45%, treat it at 30°C for (9) minutes, take it out, wash it with water, dry it, and put it in H 2 SO 4 and HF mixed aqueous solution, H 2 SO 4 The amount concentration of the substance is 0.52mol / L, and the concentration of the substance of HF is 4ppm, with the metal plate as the working electrode, Pt as the counter electrode, saturated ...

Embodiment 3

[0044] like figure 1 Shown, the manufacture method of Fe-Ni-Cr alloy fuel cell bipolar plate, it comprises the steps:

[0045] (1) Selection and smelting of alloy components: according to the ingredients of 39% Fe (atomic percentage), 33% Ni (atomic percentage), and 28% Cr (atomic percentage), Fe is obtained by vacuum induction melting 39 Ni 33 Cr 28 alloy;

[0046] (2) metal plate forming processing: the above alloy is processed into a metal plate with a flow field according to a conventional method;

[0047] (3) Surface chemical treatment: place the metal plate in a 50% HF aqueous solution, treat it at 20°C for 7 minutes, take it out, wash it with water, dry it, and put it in H 2 SO 4 and HF mixed aqueous solution, H 2 SO 4 The amount concentration of the substance is 0.48mol / L, and the concentration of the substance of HF is 6ppm, with the metal plate as the working electrode, with Pt as the counter electrode, saturated calomel electrode (SCE) as the reference electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com