Direct shearing type reinforcing assembly

A reinforcement component, shear type technology, applied in the direction of building maintenance, construction, building construction, etc., can solve the problems of large functional interference of the structure in use, reduce the clear height of the structure, increase the self-weight of the structure, etc., and achieve the reliability of reinforcement quality. High, reliable effect of eliminating radial clearance, stiffness and load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

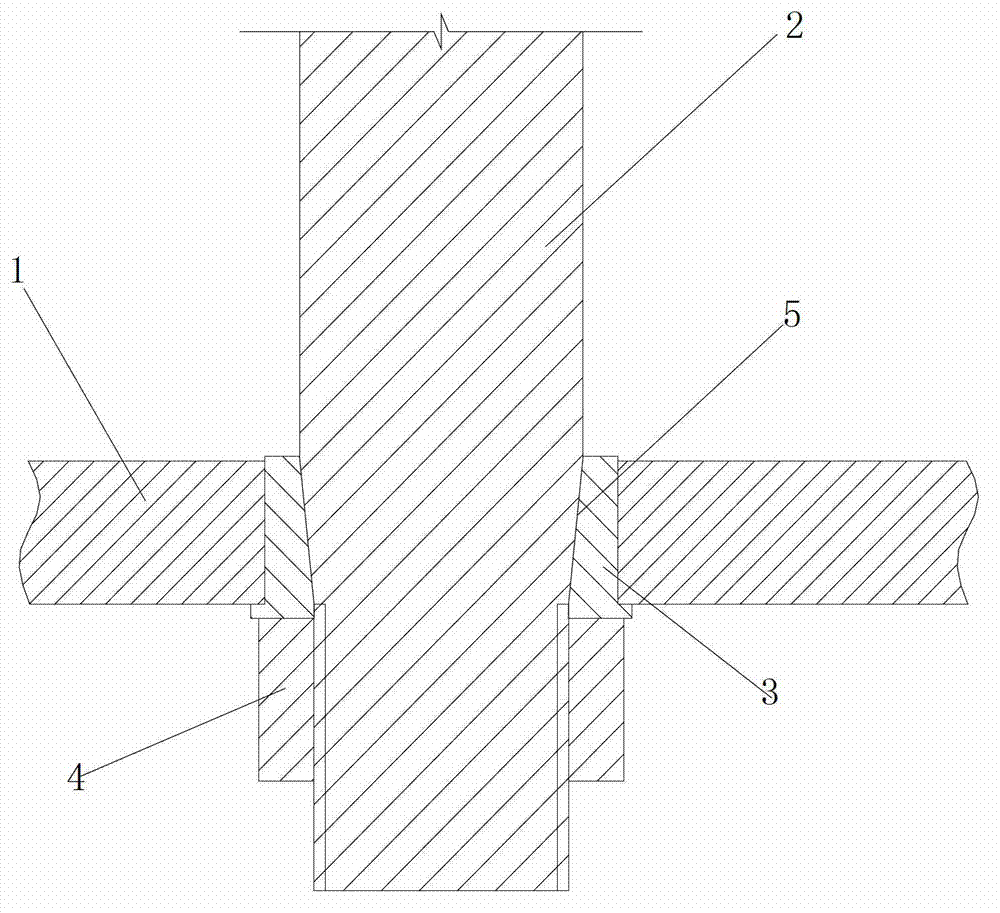

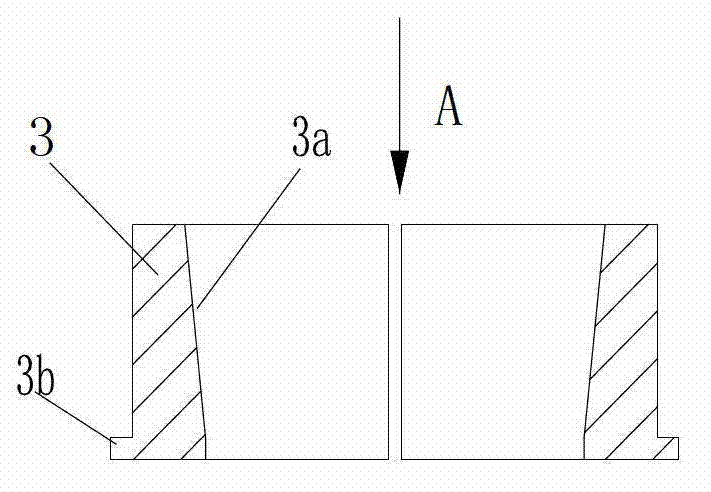

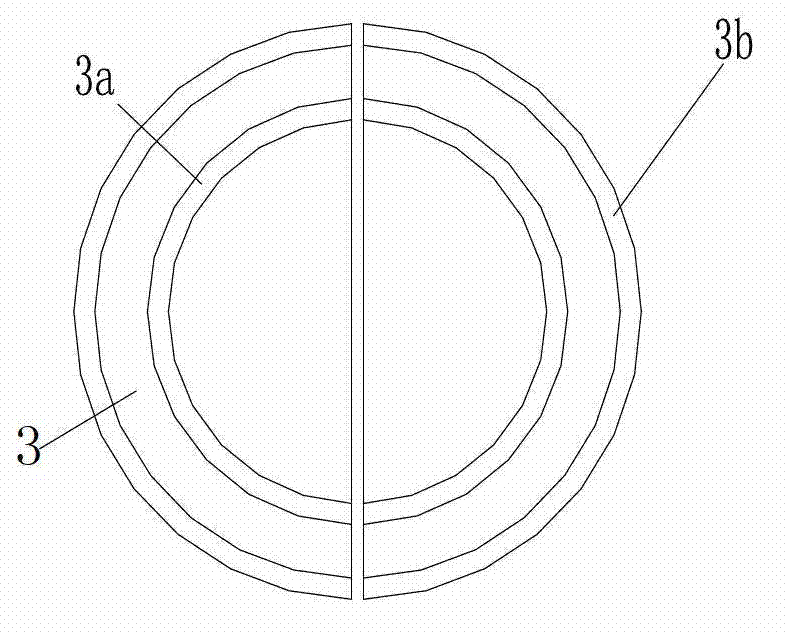

[0020] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the structure of the expansion sleeve of the present invention, image 3 for figure 2 View along direction A, Figure 4 It is a schematic diagram of the installation process of the present invention, Figure 5 The structural diagram is used for the present invention, as shown in the figure: the direct shear type reinforcement assembly of this embodiment includes a reinforcement plate 1 that is close to the member to be reinforced and an anchor bolt that fixes the reinforcement plate 1 to the member to be reinforced pair, the anchor bolt pair includes an anchor bolt 2, an expansion sleeve 3 and an anchor nut 4, the expansion sleeve 3 is a split structure formed by at least two half-columns, and is fitted with the anchor bolt 2 through a tapered surface pair to cover the anchor Bolt 2, the expansion sleeve 3 is pressed into the connection hole 1a of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com