Device for preventing cylinder from moving forwards and crane

The technology of a non-return device and an oil cylinder is applied to the device for preventing the forward movement of the oil cylinder and the field of cranes, which can solve the problems of easy forward movement of the oil cylinder and accidents, and achieve the effect of avoiding the forward movement of the oil cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

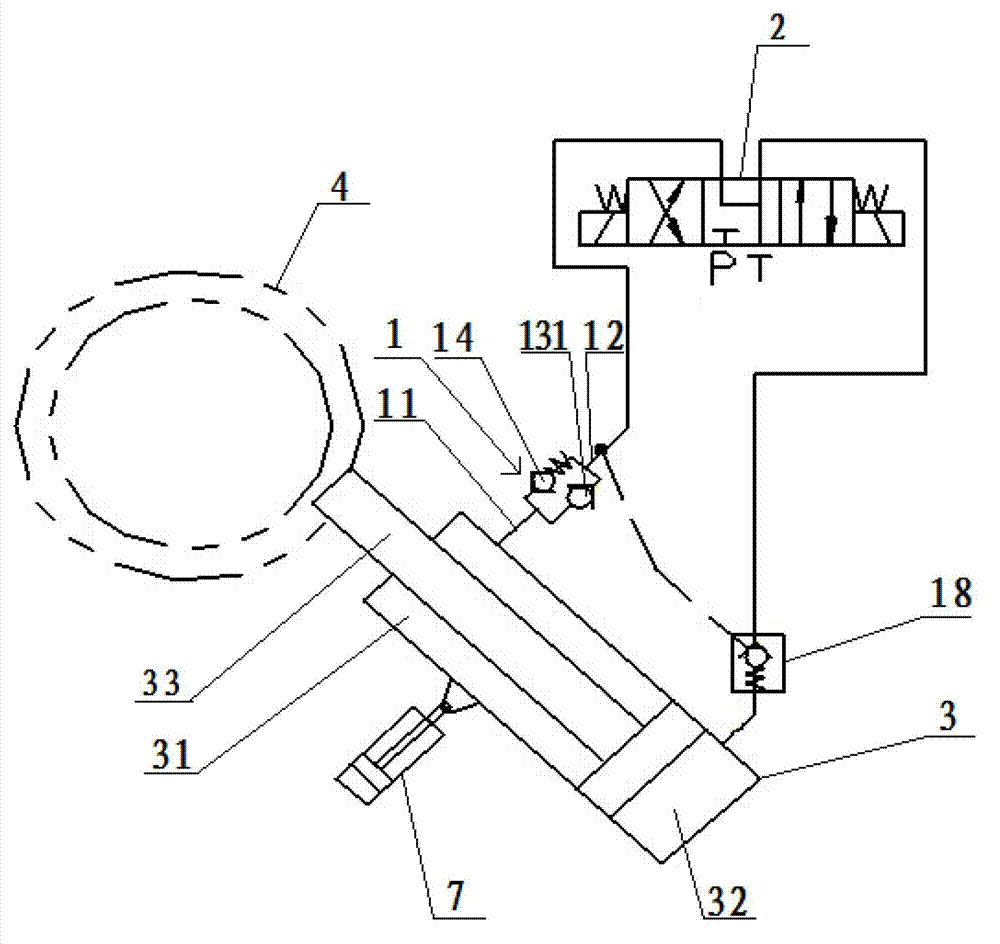

[0067] Such as image 3 As shown, the check device 1 in this embodiment includes a check valve 131 and a spring check valve 14, wherein:

[0068] The oil outlet of the check valve 131 is connected in parallel with the oil inlet of the spring check valve 14 and communicates with the first oil port 11 of the check device 1 .

[0069] The oil inlet port of the check valve 131 is connected in parallel with the oil outlet port of the spring check valve 14 and communicates with the second oil port 12 of the check device 1 .

[0070] During the process of liquid flowing out from the rod chamber 31 of the oil cylinder 3, the liquid flowing out from the rod chamber 31 of the oil cylinder 3 passes through the first oil port 11 of the check device 1 from the oil inlet port of the spring check valve 14 to the spring check valve. When the oil outlet direction of the valve 14 flows, if the pressure of the liquid exceeds the predetermined value of the spring check valve 14, the liquid can f...

Embodiment approach 2

[0072] Such as Figure 4 As shown, the check device 1 in this embodiment includes a one-way valve 132 and a throttle valve 15, wherein:

[0073] The oil outlet of the one-way valve 132 is connected in parallel with the oil outlet of the throttle valve 15 and communicates with the first oil port 11 of the check device 1 .

[0074] The oil inlet of the one-way valve 132 is connected in parallel with the oil inlet of the throttle valve 15 and communicates with the second oil port 12 of the non-return device 1 .

[0075] Similar to the principle of the spring check valve 14, the throttle valve 15 can increase the flow rate of the liquid flowing from the rod chamber 31 of the oil cylinder 3 from the oil outlet of the throttle valve 15 to the oil inlet of the throttle valve 15. resistance.

Embodiment approach 3

[0077] Such as Figure 5 As shown, the check device 1 in this embodiment includes a relief valve 16 and a one-way valve 133, wherein:

[0078] Both the oil outlet of the one-way valve 133 and the oil inlet of the relief valve 16 communicate with the first oil port 11 of the check device 1 .

[0079] Both the oil inlet port of the one-way valve 133 and the oil return port of the relief valve 16 communicate with the second oil port 12 of the check device 1 .

[0080] In this example, preferably: the one-way valve 133 is connected in series with the overflow valve 16 .

[0081] Similar to the principle of the spring check valve 14, the overflow valve 16 can also increase the flow of liquid in the rod chamber 31 of the oil cylinder 3 from the first oil port 11 of the check device 1 to the second oil port of the check device 1 12 resistance in the process, and then play the purpose of preventing the oil cylinder 3 from fleeing forward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com