Quick change joint mechanism for fluid medium

A fluid medium, fast technology, applied in mechanical equipment, pipe components, couplings, etc., to achieve the effect of easy manufacturing, automatic transfer, and smooth transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

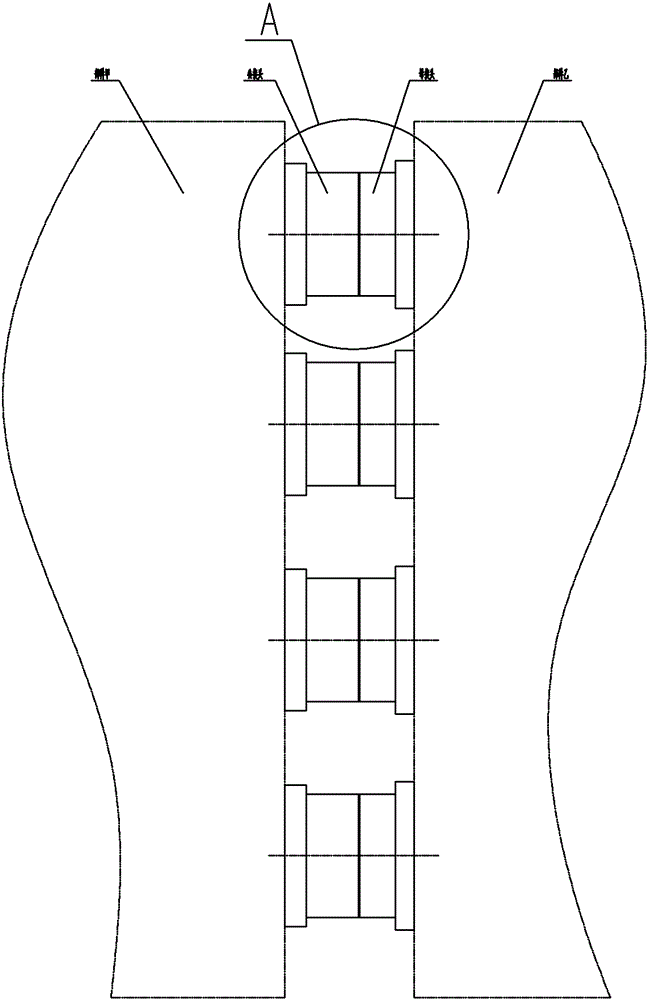

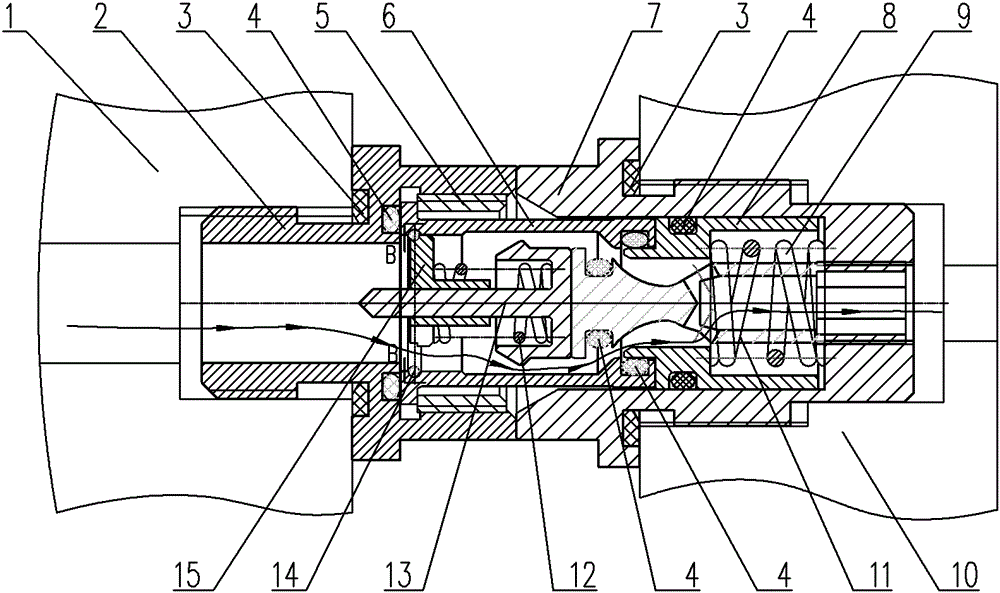

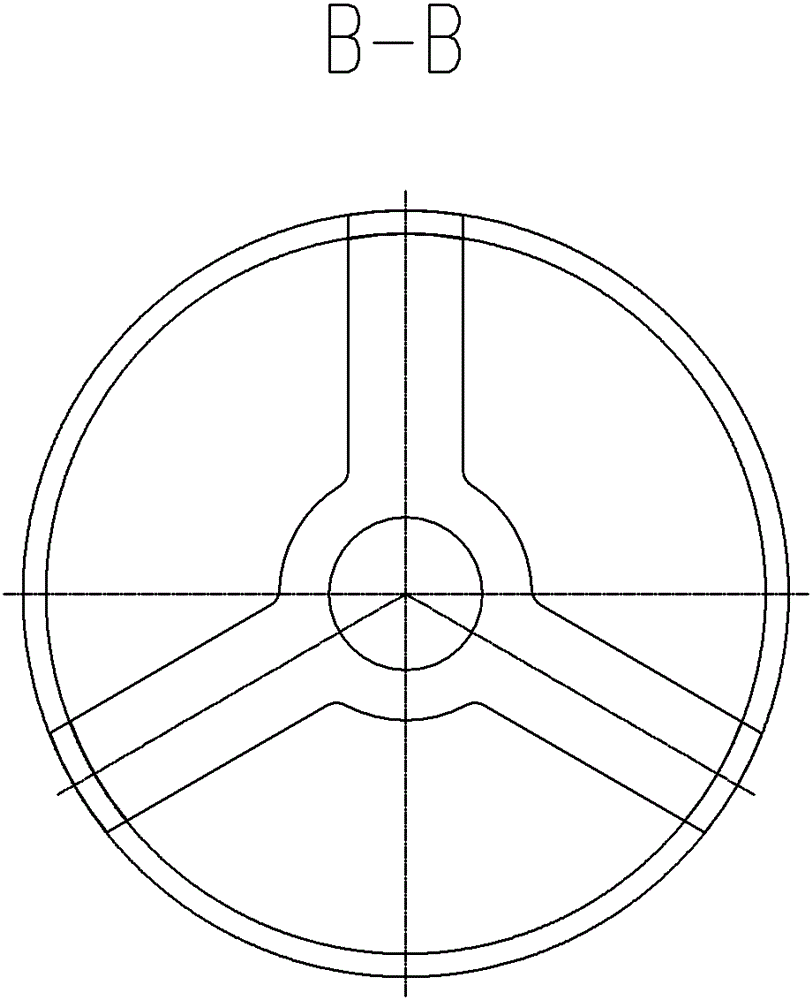

[0018] figure 1 , 2 Shown in , 3 is a specific embodiment of the present invention, which is a quick-change joint mechanism for fluid medium installed on the attachment head of the hydraulic system of the gantry milling machine. A number of combined male and female joints are installed in the middle, and each combined male and female joint is a sealed joint that is automatically formed as a whole by pushing the self-sealing male joint into the self-sealing female joint; A self-sealing male joint is mainly composed of a male housing 2, a guide ring 15, a guide sleeve 6, a piston 13, a threaded retaining sleeve 5, a spring armor 12, a sealing ring 4 and a retaining ring 14, and the connecting end of the male housing 2 is threaded Connected in Part A 1, the connection end of the male housing 2 is provided with an inlet hole for fluid medium, and the right end of the male housing 2 is provided with a penetration hole communicating with the inlet hole, and the inner bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com