Fuse SMA (shape memory alloy) wire space connecting and disconnecting mechanism

A technology of spatial connection and separation mechanism, which is applied to the docking device, projectile, self-propelled projectile and other directions of aerospace vehicles, can solve the problems of poor impact load capacity and incomplete unlocking, etc., and achieves strong impact load capacity, complete unlocking, and improved The effect of using reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

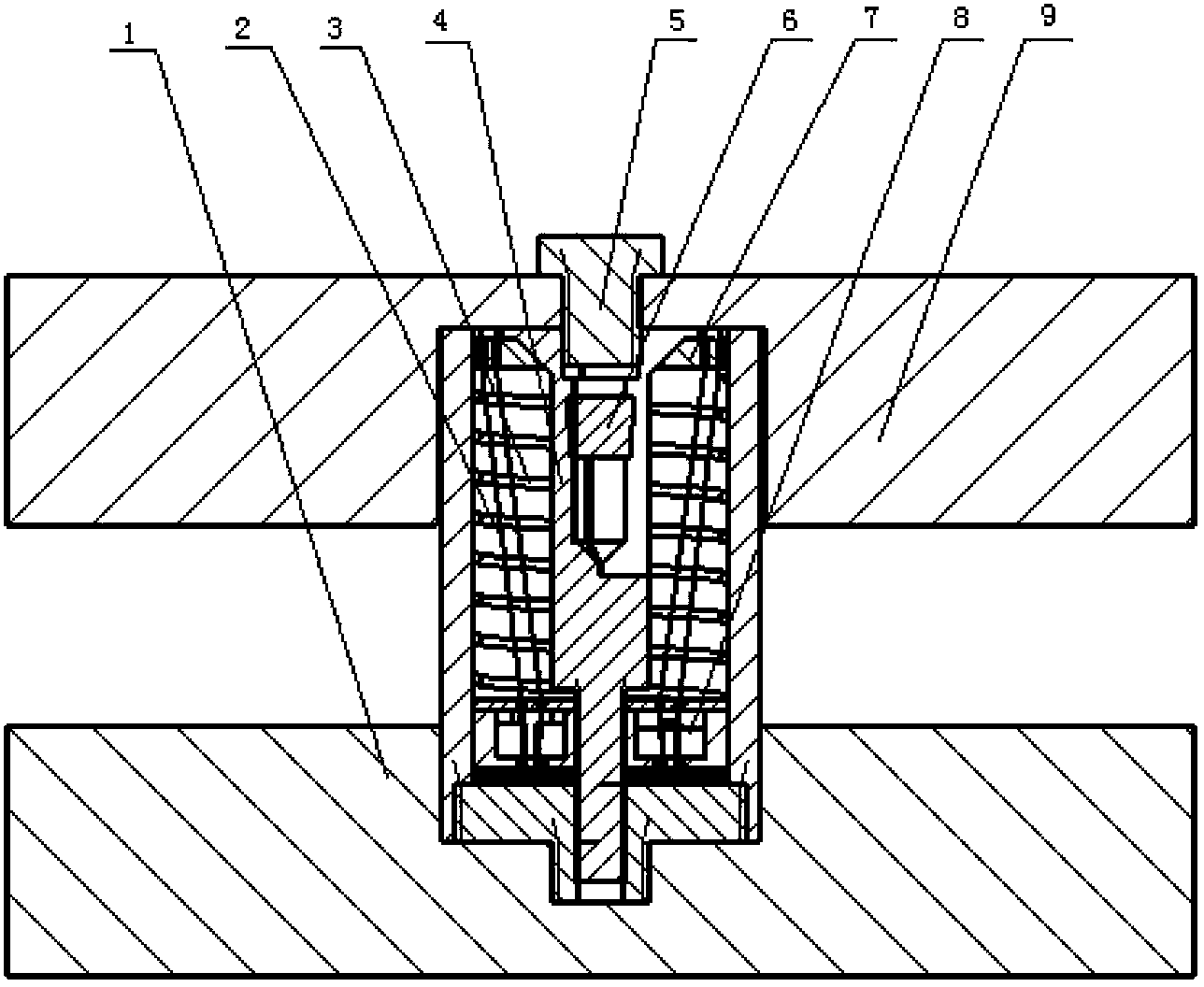

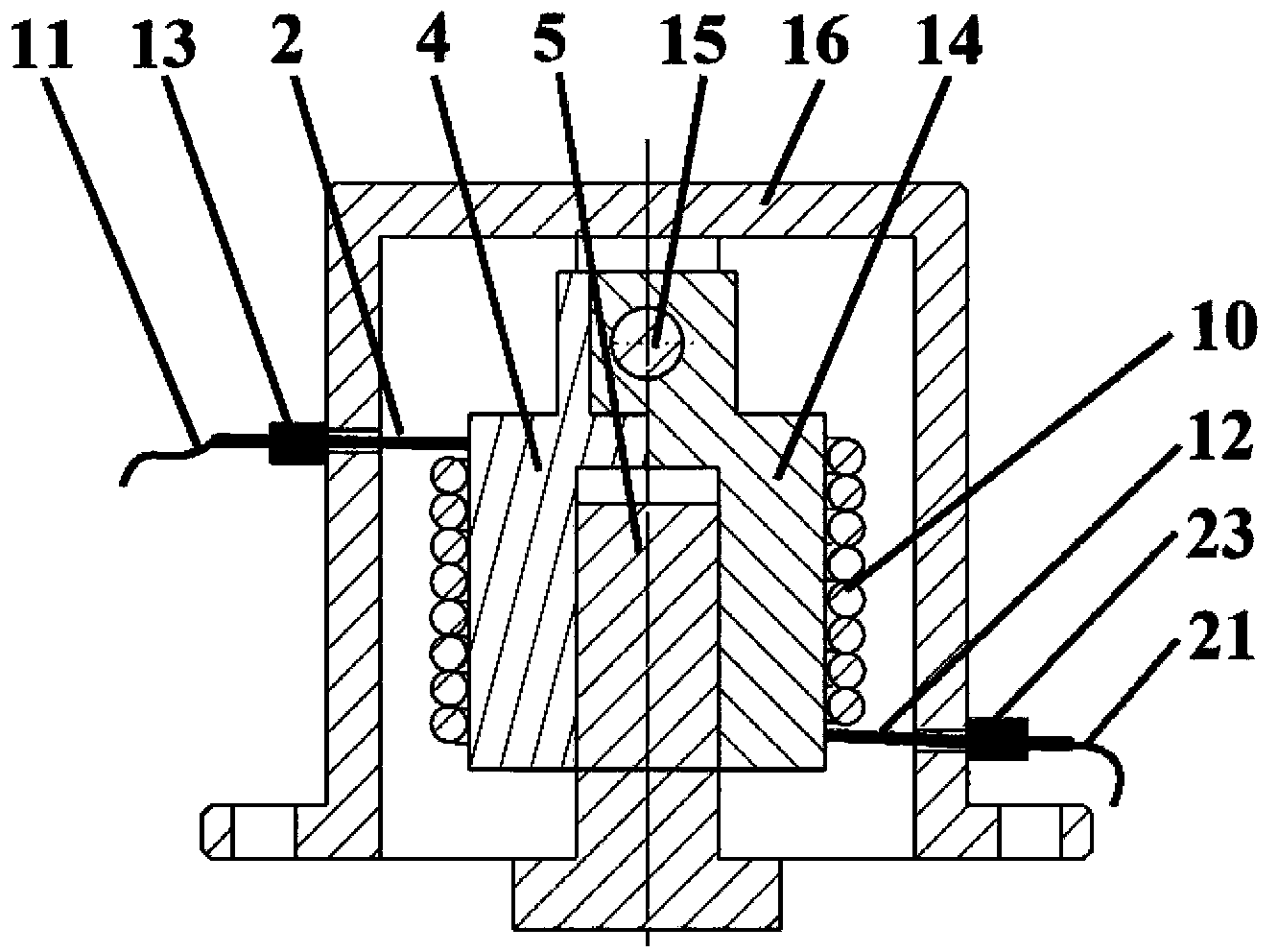

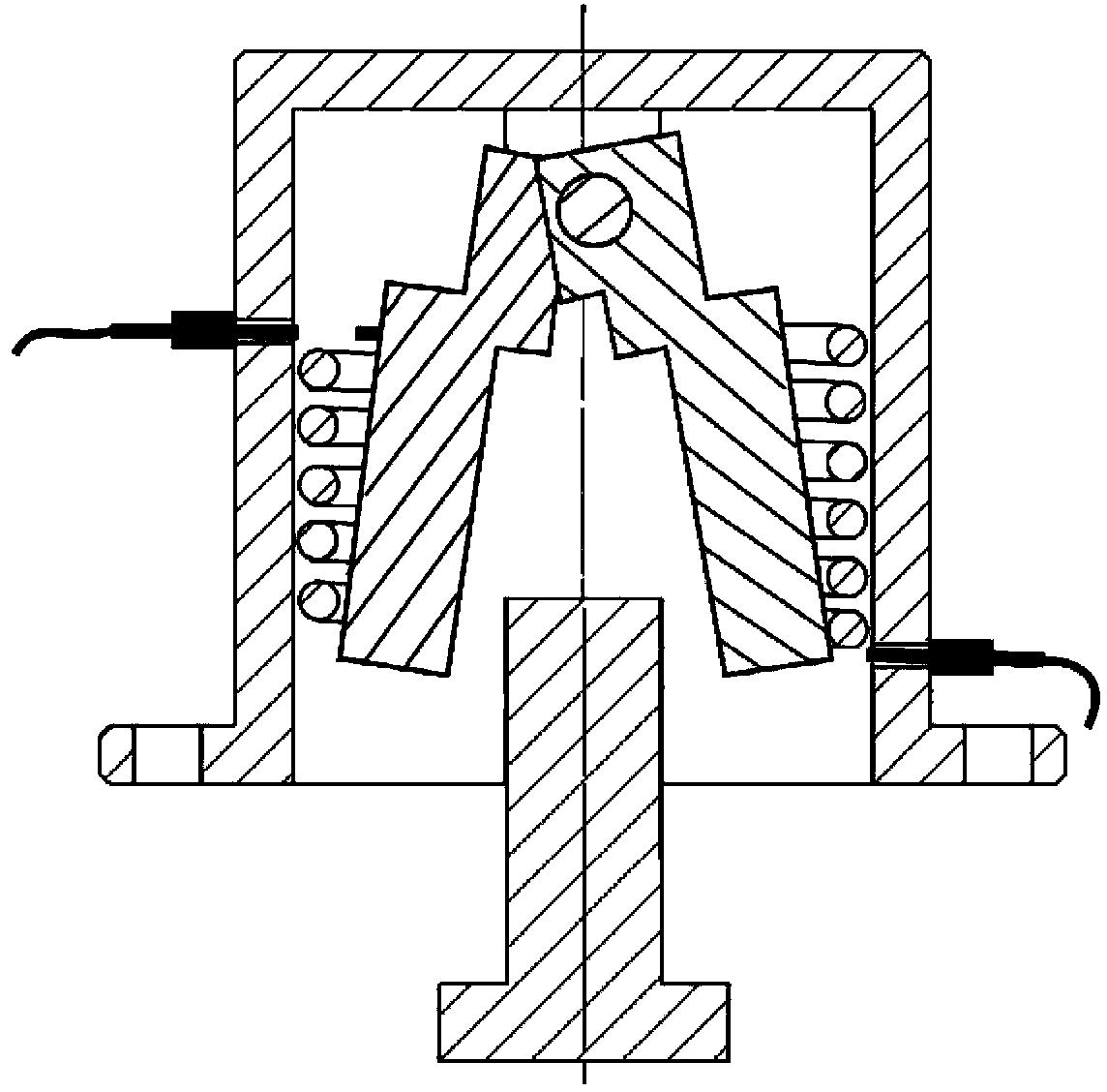

[0034]According to one aspect of the present invention, the space connection and separation mechanism of the fuse SMA wire is provided with: a split nut, used for threaded connection with a bolt, which is completely divided into two petals, and the two petal nuts are provided with matching shaft holes , and use a shaft to pass through the two holes in turn to connect with the shell, the two-lobe nuts can rotate in the direction away from each other in the axial direction, so that the two-lobe nuts can be fully opened; the binding spring of the split nut is a cylindrical helical twist The spring is arranged on the outside of the split nut. In the connected state, it is in a tightened state, and its inner diameter is equal to the outer diameter of the split nut, so as to bind the split nut tightly, thus maintaining the radial constraint on the split nut. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com