A sma-driven notch bolt connection and separation mechanism

A separation mechanism and separation structure technology, which is applied in the direction of motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of poor anti-vibration and shock performance, inability to monitor release, incomplete unlocking, etc. The effect of short separation time of mechanism and reduction of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

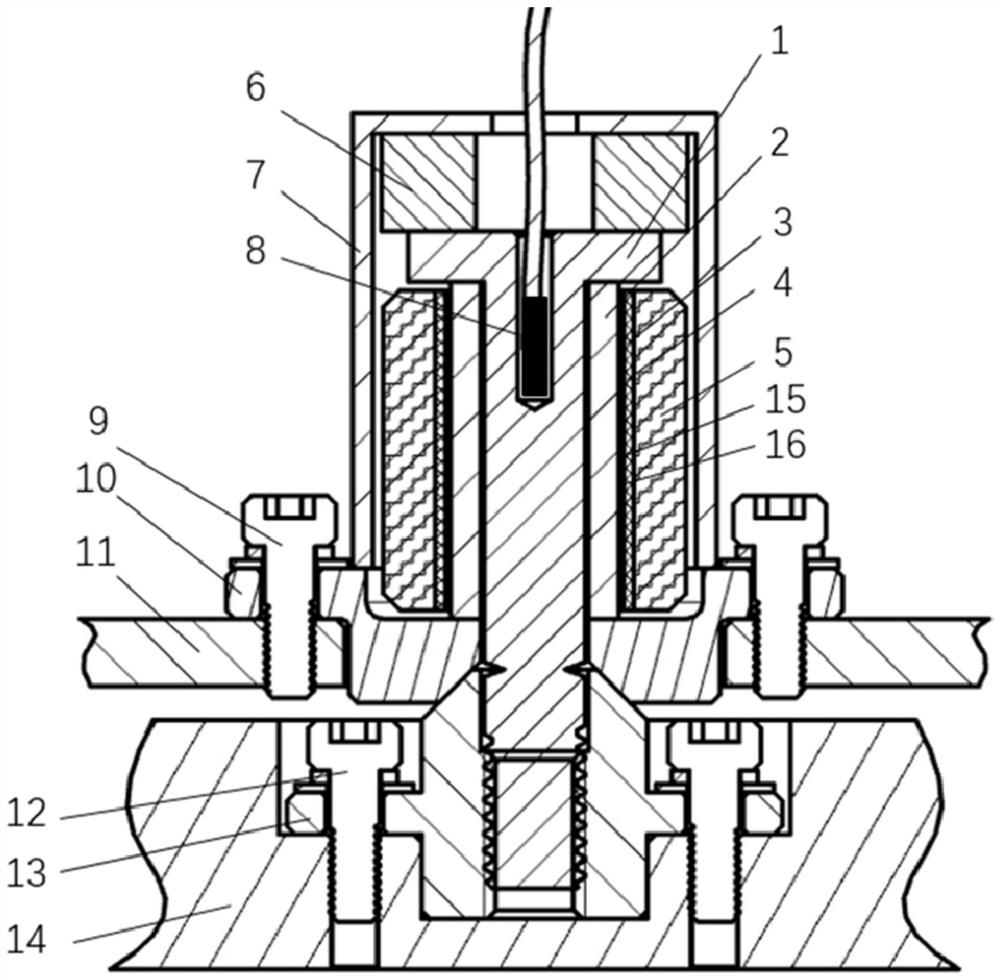

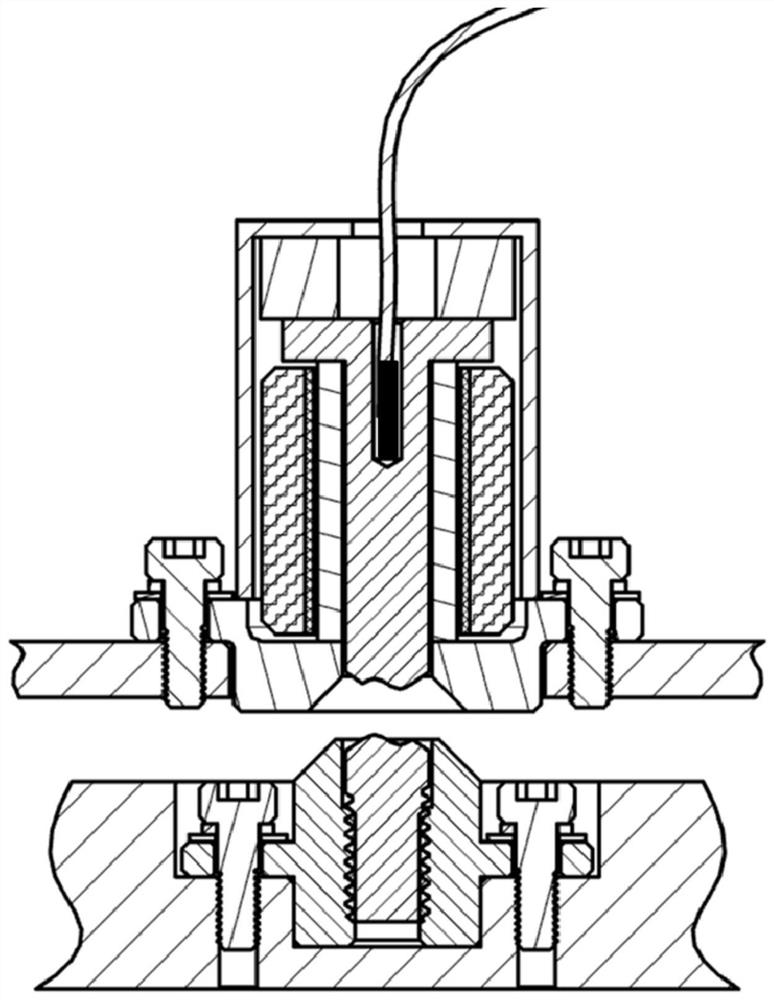

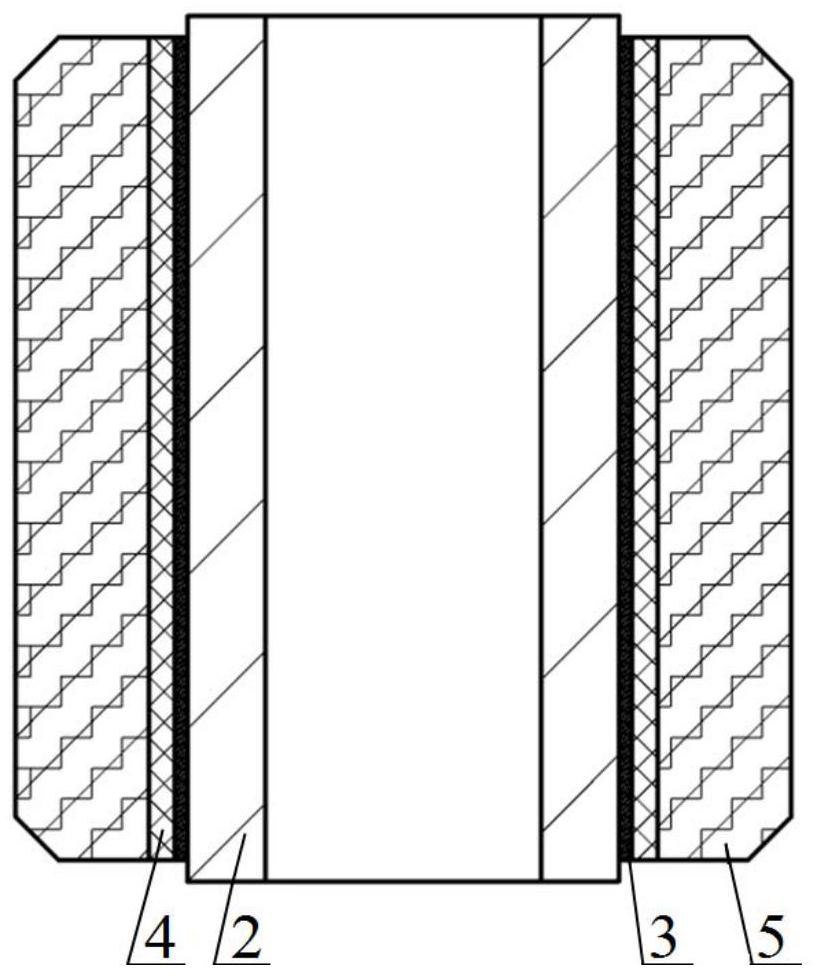

[0040] Such as figure 1 As shown, in the connected state, the notch bolt 1 of the present invention is constrained by the SMA tube 2 so that it cannot move axially; the shell 7 and the separation structure substrate 10 are connected to the separation structure 11 through the first bolt 9, and the structure substrate 13 is fixed. Connected to the fixed structure 14 through the second bolt 12; after the screw part of the notch bolt 1 passes through the SMA pipe 2 and the separation structure substrate 10, it is screwed on the fixed structure substrate 13, thereby connecting and compressing the SMA pipe 2, The separation structure base plate 10 and the fixed structure base plate 13; the separation structure base plate 10 and the fixed structure base plate 13 adopt conical surface cooperation, and under the action of the notch bolt 1, the separation structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com