Lithium-ion battery positive tab and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied to battery components, circuits, electrical components, etc., can solve the problems of cumbersome and complicated processes, high production costs, false welding resistance, etc., achieve small resistance, save resources, and avoid false welding. The effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

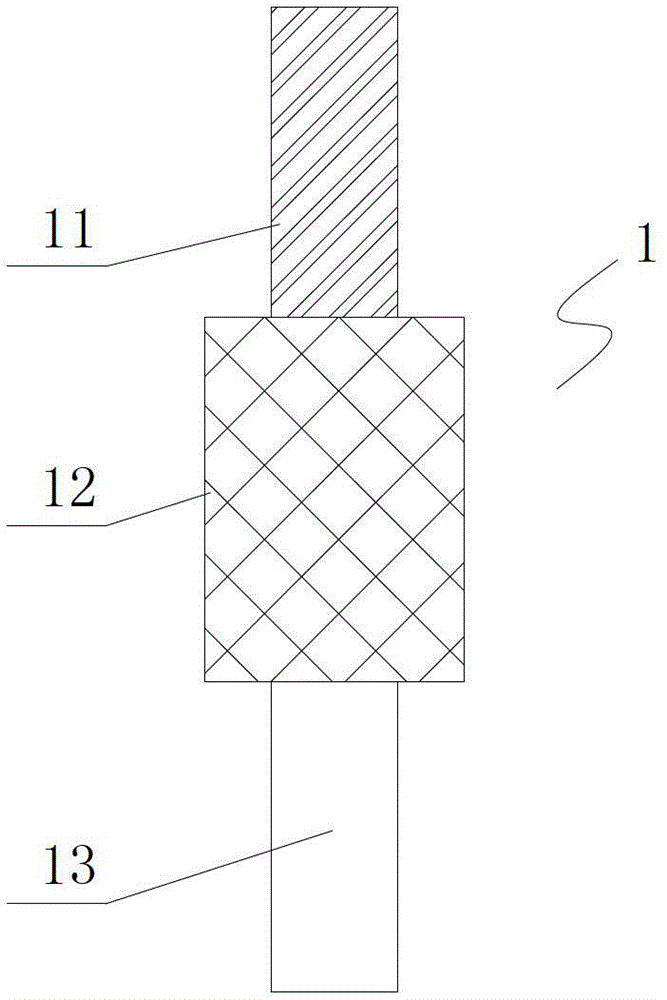

[0038] Such as figure 1 As shown, the positive tab of the lithium ion battery of the present invention includes an aluminum strip 1, the end of the aluminum strip 1 is provided with a nickel-plated layer 11, and the middle position of the aluminum strip 1 is used for bonding. The other end of the ear gel 12 is a non-nickel-plated part 13 .

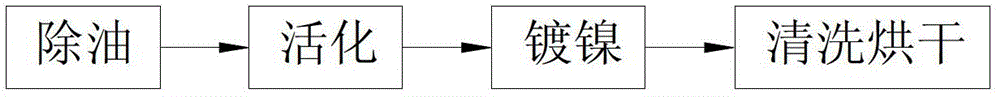

[0039] The manufacture method of lithium-ion battery positive electrode tab of the present invention, concrete steps are as follows

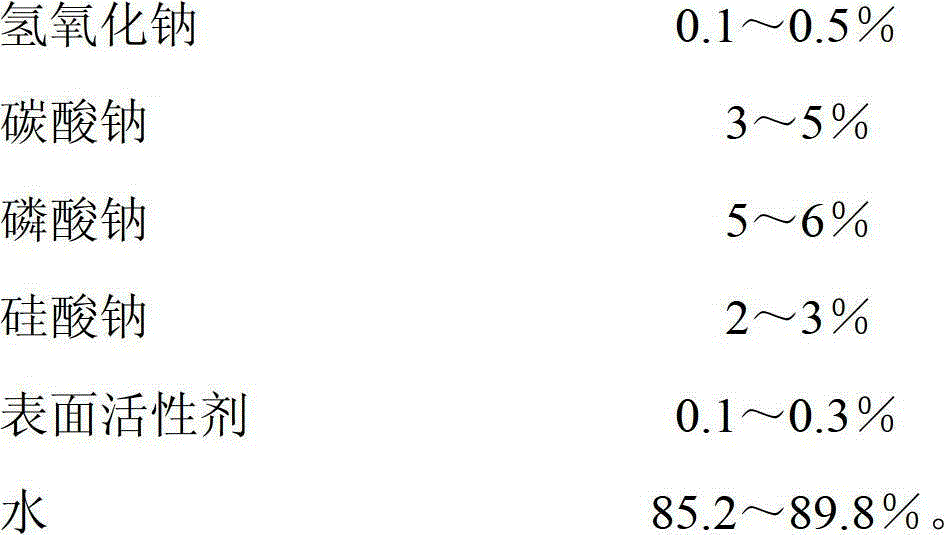

[0040] (1) Degreasing: put the end part of the aluminum lug made of aluminum strip into a degreasing liquid to degrease under certain conditions, and clean it with water after degreasing;

[0041] (2) Activation: Put the end part of the aluminum lug that has been cleaned after degreasing into the activation solution at room temperature for activation, and clean it with water after activation;

[0042] (3) Nickel plating: Put the end part of the activated aluminum tab into an electroless nickel plating solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com