Manufacturing method for USB series change-over offline

A production method and a technology for connecting wires, which are applied in the manufacture, connection, and electrical components of contact boxes/bases, can solve the problems of affecting the appearance of the product, the inability to match the shell 02, and the inability to ensure that the core wires are not exposed, etc., to achieve improvement The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

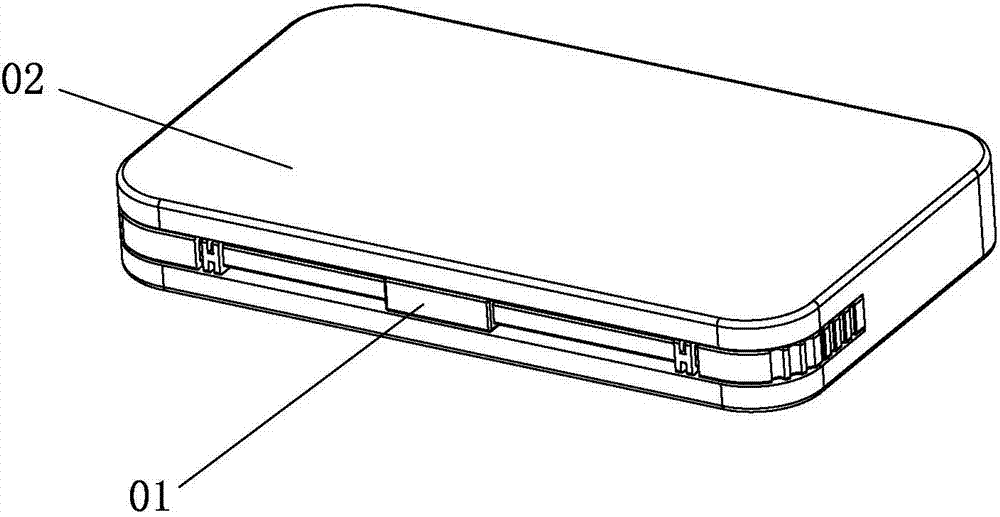

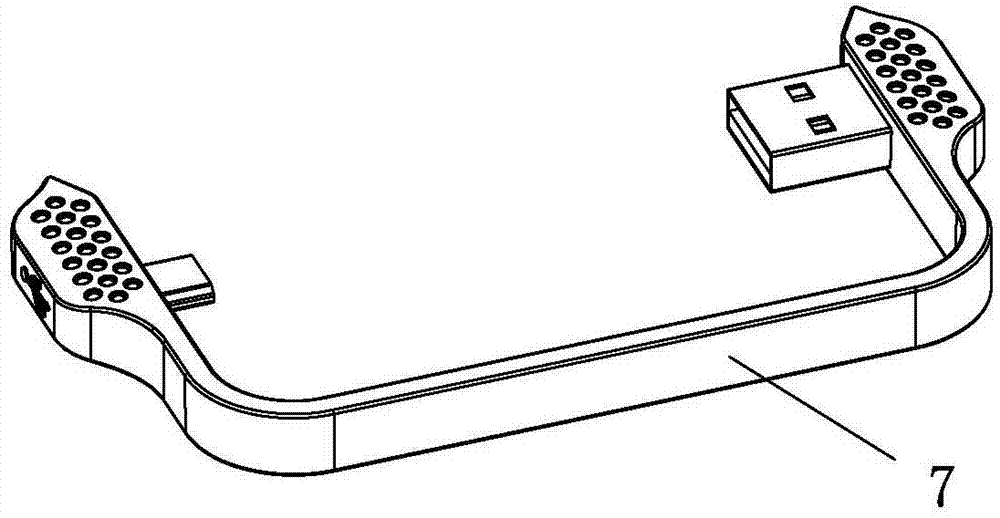

[0024] Figure 5 ~ Figure 8 A schematic diagram showing the fabrication of the USB series adapter cable of the present invention is shown. The present invention proposes USB

[0025] The method of serial transfer line has the following steps:

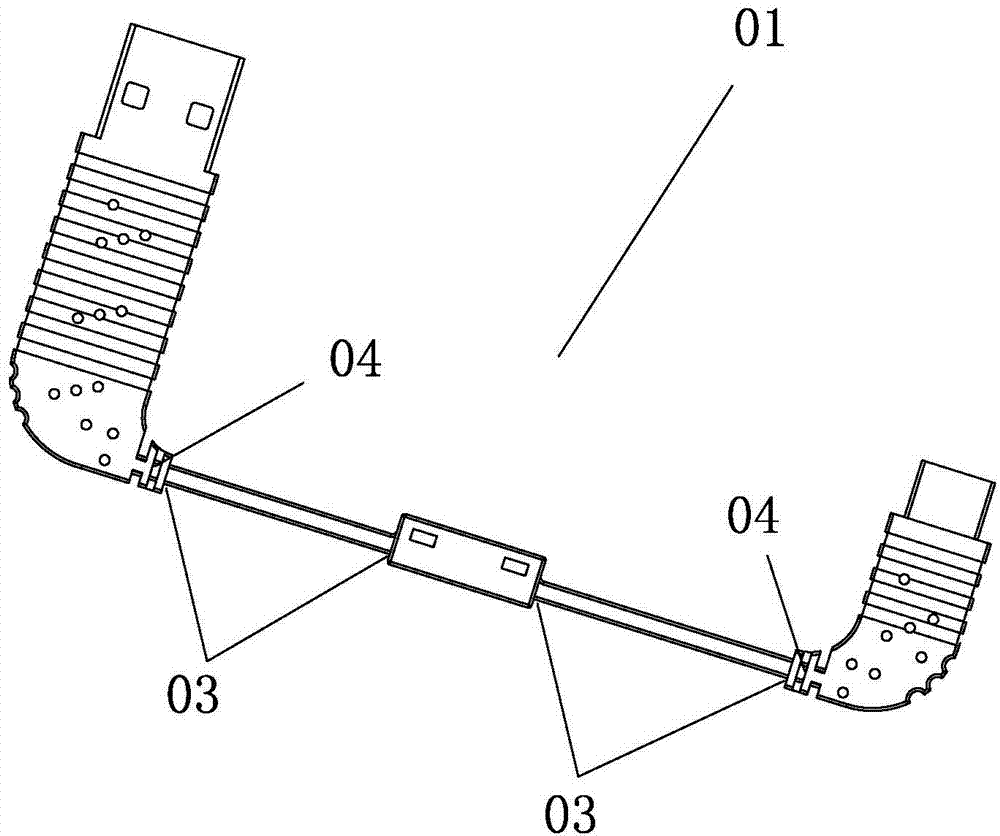

[0026] Step 1: If Figure 5 As shown, select the enameled wire 1 with appropriate thickness and required length, solder its one end with the first plug 2 with tin, and solder its other end with the second plug 3 with tin to make a semi-finished transition wire.

[0027] Step 2: Set up the mold for the first molding and the mold for the second molding on two vertical injection molding machines

[0028] Put the plastic, such as PVC, TPU or TPE into the vertical machine hopper of the injection molding machine, first bake the plastic, the baking temperature is 80 degrees Celsius, and the product can be injected after baking for 2 hours .

[0029] Step 3: Set the barrel temperature and injection molding parameters of the two vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com