Medical waste classification and recovery device for cardiovascular department

A medical waste and recycling device technology, applied in the medical field, can solve the problems of garbage classification, inability to recycling devices, and single function, and achieve the effects of preventing pollution, being difficult to expose, and being stable in opening and closing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

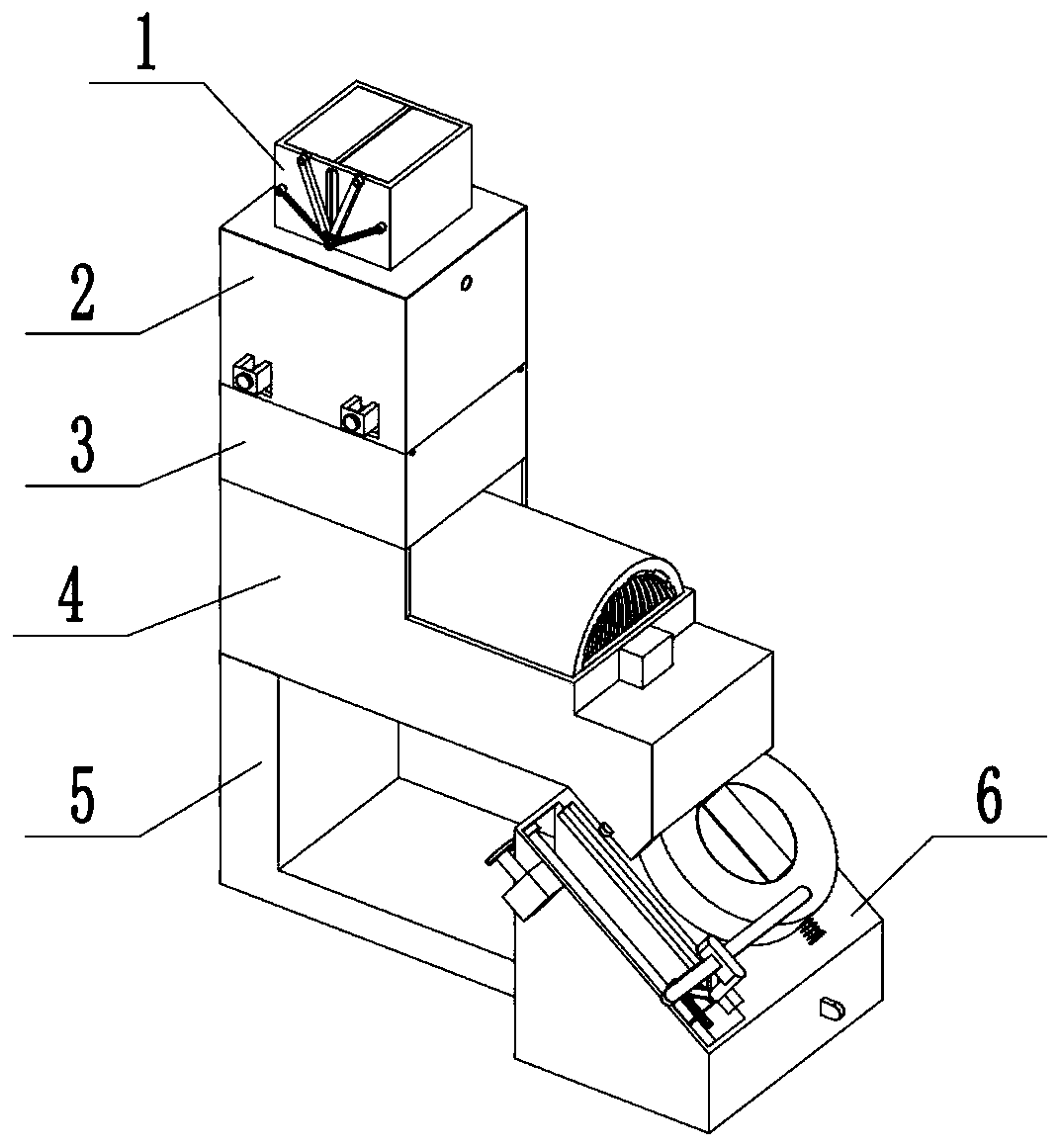

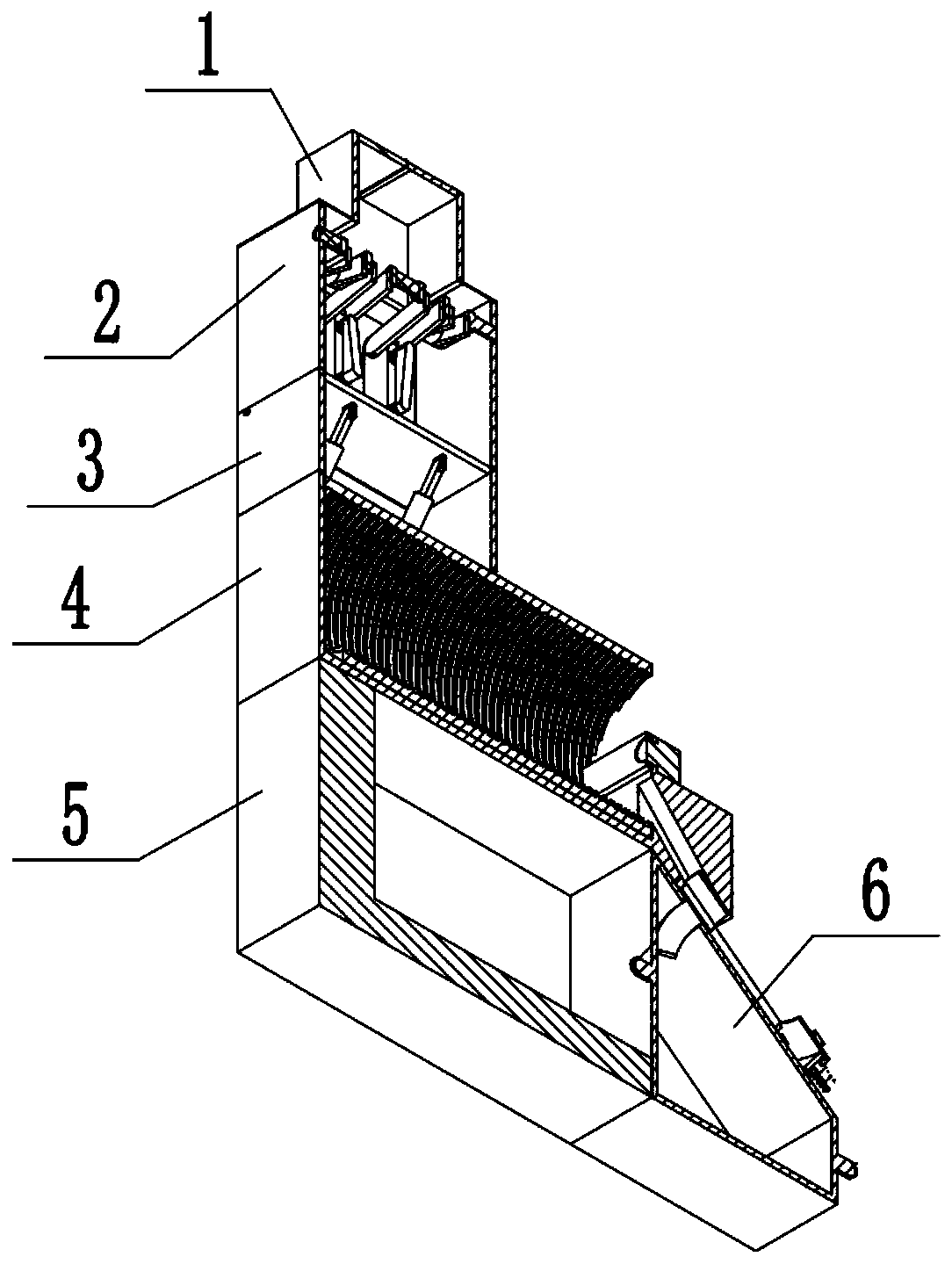

[0048] Combine below Figure 1-30 Describe this embodiment, a sorting and recycling device for cardiovascular medical waste, including a closed frame assembly 1, a squeeze crushing assembly 2, a buffer assembly 3, an inner end transport assembly 4, an auxiliary fixing frame 5 and a separation assembly body 6, the closed frame assembly 1 is fixedly connected and communicated with the extrusion crushing assembly 2, the extrusion crushing assembly 2 is fixedly connected and communicated with the buffer assembly 3, and the inner transport assembly 4 is fixed with the buffer assembly 3 Connected and communicated, the auxiliary fixing frame 5 is fixedly connected with the inner end transportation assembly 4, the inner end transportation assembly 4 is fixedly connected and communicated with the separation assembly 6, and the auxiliary fixing frame 5 is fixedly connected with the separation assembly 6.

specific Embodiment approach 2

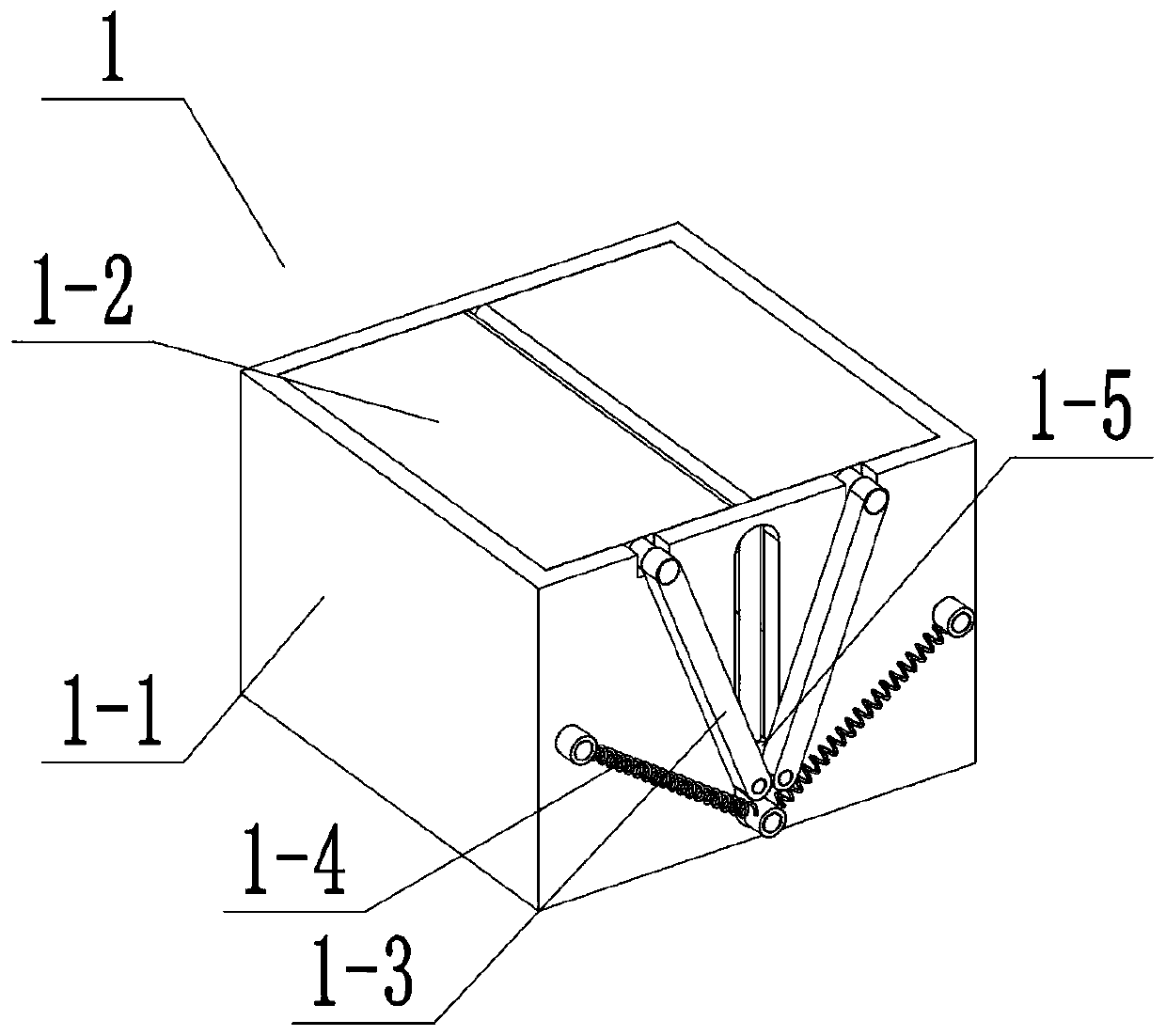

[0050] Combine below Figure 1-30 Describe this embodiment, this embodiment will further explain Embodiment 1, the closed frame assembly 1 includes a closed frame body 1-1, a closed plate 1-2, a drive rod 1-3, and a drive push spring 1-4 , Fader 1-5, Gap 1-6, Hinged Post One 1-7, Mid-end Sliding Post 1-8, Hinged Post Two 1-9, Sliding Post Sliding Hole 1-10, Hinged Post Three 1-11, Hinged Column four 1-12 and hinged column five 1-13, the closed plate 1-2 is rotationally connected with the closed frame body 1-1, the closed plate 1-2 is hingedly connected with the drive rod 1-3, and the drive rod 1-3 The lower end of the push spring is rotatably connected to the pusher 1-5, and the left and right ends of the drive push spring one 1-4 are hingedly connected to the closed frame body 1-1, and the middle end of the drive push spring one 1-4 is hingedly connected to the push push spring one 1-4. On the child 1-5, the notch 1-6 is arranged on the upper side of the front end of the clo...

specific Embodiment approach 3

[0053] Combine below Figure 1-30 This embodiment will be described. This embodiment will further describe Embodiment 1. The extrusion crushing assembly 2 includes an extrusion crushing outer frame 2-1, a cover plate 2-2, a driving crankshaft 2-3, and an extrusion outer frame 2-4, N-shaped frame 2-5, adjusting threaded rod 2-6, crankshaft rotating hole 2-7, hollow groove 1 2-8, rotating hole 1 2-9, lug plate 2-10, extrusion rod 2- 11. Squeeze push spring 2-12, squeeze sliding hole 2-13, connecting rod 2-14, drive straight tooth 2-15, input straight tooth 2-16, squeeze motor 2-17 and fix the motor Plate 2-18, the cover plate one 2-2 is fixedly connected to the extruded and crushed outer frame 2-1, the crank shaft hole 2-7 runs through the left and right ends of the extruded and crushed outer frame 2-1, and the hollow groove one 2 -8 is set on the extruded and crushed outer frame 2-1, the ear plate 2-10 is set in the hollow groove 2-8, the turning hole 2-9 is set on the ear pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com