Electronically controlled directionally rotating single-phase self-starting permanent-magnet synchronous motor

A directional rotation, electronic control technology, applied in the direction of a single motor speed/torque control, electronic commutator, etc., can solve problems such as high noise and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The motor of the embodiment of the present invention is improved on the basis of the motor described in Embodiment 1 of the prior patent application CN201110100111.6 specification of the designer of the present invention.

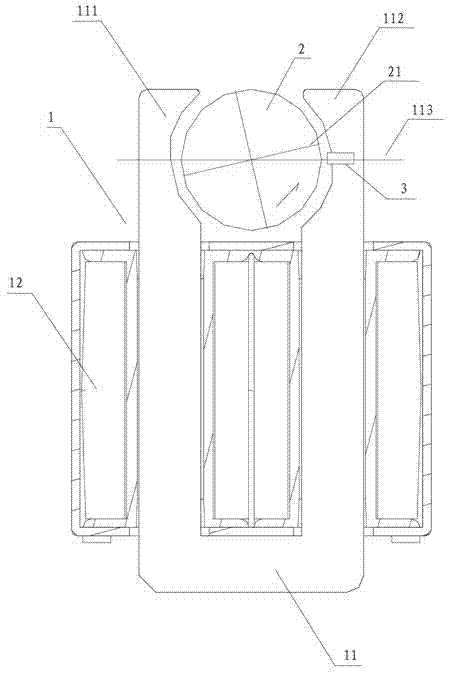

[0025] The basic electromagnetic structure of the miniature permanent magnet synchronous motor in the embodiment of the present invention is as follows: figure 1 As shown, it inherits from the specification of CN201110100111.6 figure 1 ,include:

[0026] ——The stator 1 is mainly composed of a U-shaped iron core 11 and a winding 12; the upper part of the iron core 11 is formed to surround the left and right poles of the rotor 2—the left pole 111 and the right pole 112; the winding 12 is formed by penetrating into the yoke of the iron core 11 The left arm and the right arm each have one coil connected in series or in parallel;

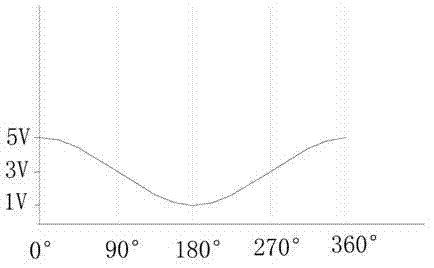

[0027] ——The rotor 2 is a permanent magnet rotor, magnetized by a radially symmetrical sine wave to N and S poles, inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com