Electronically-controlled U-shaped iron core single-phase permanent-magnet synchronous motor-driven centrifugal pump

A synchronous motor and single-phase permanent magnet technology, applied in the field of centrifugal pumps, can solve problems such as temperature rise and loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

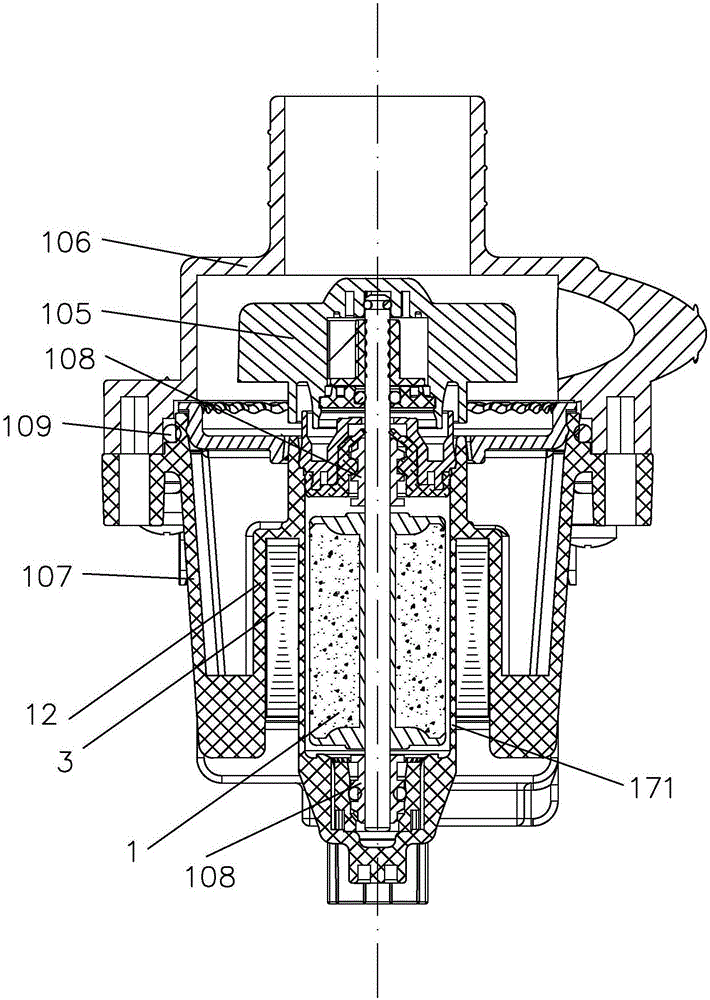

[0019] The basic mechanical structure of the centrifugal pump in the embodiment of the present invention is as follows: figure 1 shown, including:

[0020] ——U-shaped core single-phase permanent magnet synchronous motor ( figure 1 It shows the laminated iron core 3 and winding 12 of the motor stator and the section of the permanent magnet rotor 1) and the centrifugal impeller 105 coaxially driven by a starting mechanism. The centrifugal impeller 105 has four blades. The number of blades can also be 3, 5 or 6, but preferably not more than 8, and if an odd number of blades is used, it is more conducive to reducing vibration and noise. The impeller is injection molded and has a diameter of 60mm. The impeller should not be too large so that the moment of inertia is too large, so as to cooperate with the not too large starting torque of the motor; but it should not be too small, so as to have enough moment of inertia to adapt to the present invention.

[0021] - the pump cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com