Small-sized electronically-controlled centrifugal pump driven by single-phase self-starting permanent-magnet synchronous motor

An electronic control and permanent magnet synchronization technology, which is applied in the direction of single motor speed/torque control, motor control, mechanical energy control, etc., can solve the problems of temperature rise and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

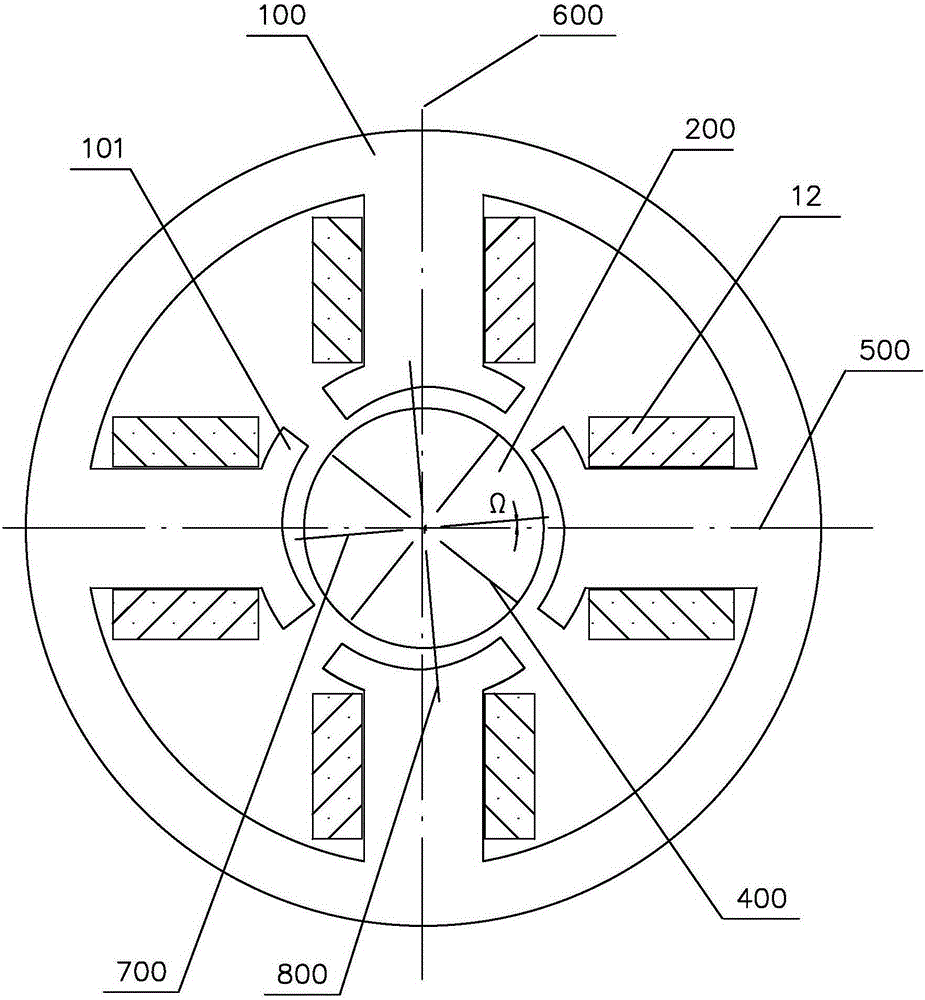

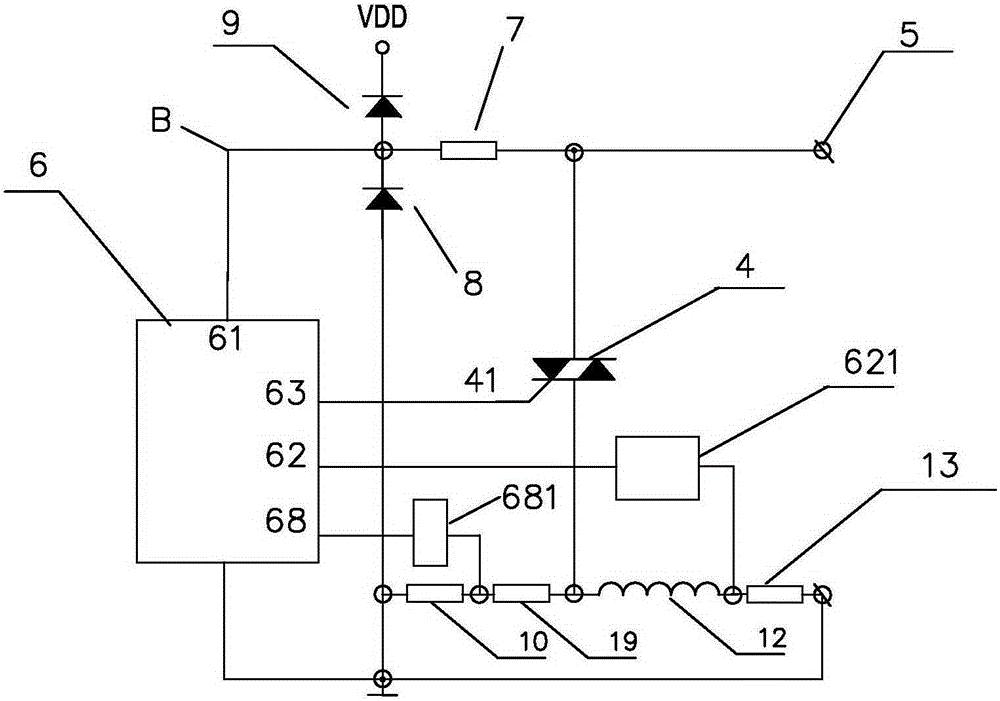

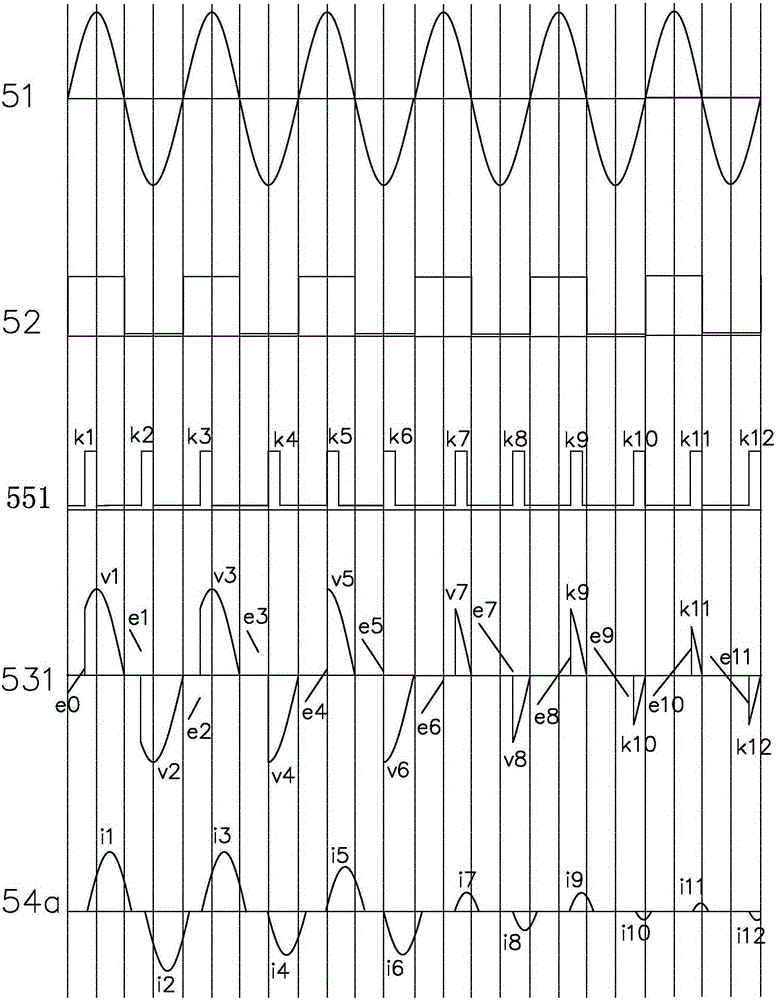

[0018] The basic mechanical structure of the centrifugal pump in the embodiment of the present invention is as follows: Figure 4 shown, including:

[0019] - motor 2 fixed to the casing;

[0020] ——Centrifugal impeller 1 directly connected to the output shaft of the motor and rotating counterclockwise, which has 4 blades; the number of blades can also be 3, 5 or 6, but preferably not more than 8, and as odd as possible , to reduce vibration noise. The impeller is injection molded with a diameter of 100mm. The impeller should not be larger, and the moment of inertia should be as small as possible to match the starting torque of the motor 2 which is still not too large;

[0021] ——The motor 2 is an inner rotor motor, including a stator 100 and a permanent magnet rotor 200 .

[0022] The basic electromagnetic structure of the motor of the centrifugal pump in the embodiment of the present invention is as follows: figure 1 shown, including:

[0023] ——The rotor 200 is a 4-po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com