Electric vehicle drive control apparatus

An electric locomotive and electric control technology, which is applied to control devices, electric devices, electric braking systems, etc., can solve the problems of deterioration of vehicle ride feel, decrease in deceleration, and prolongation of braking distance, so as to improve ride feel, reduce Effects of small deceleration changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

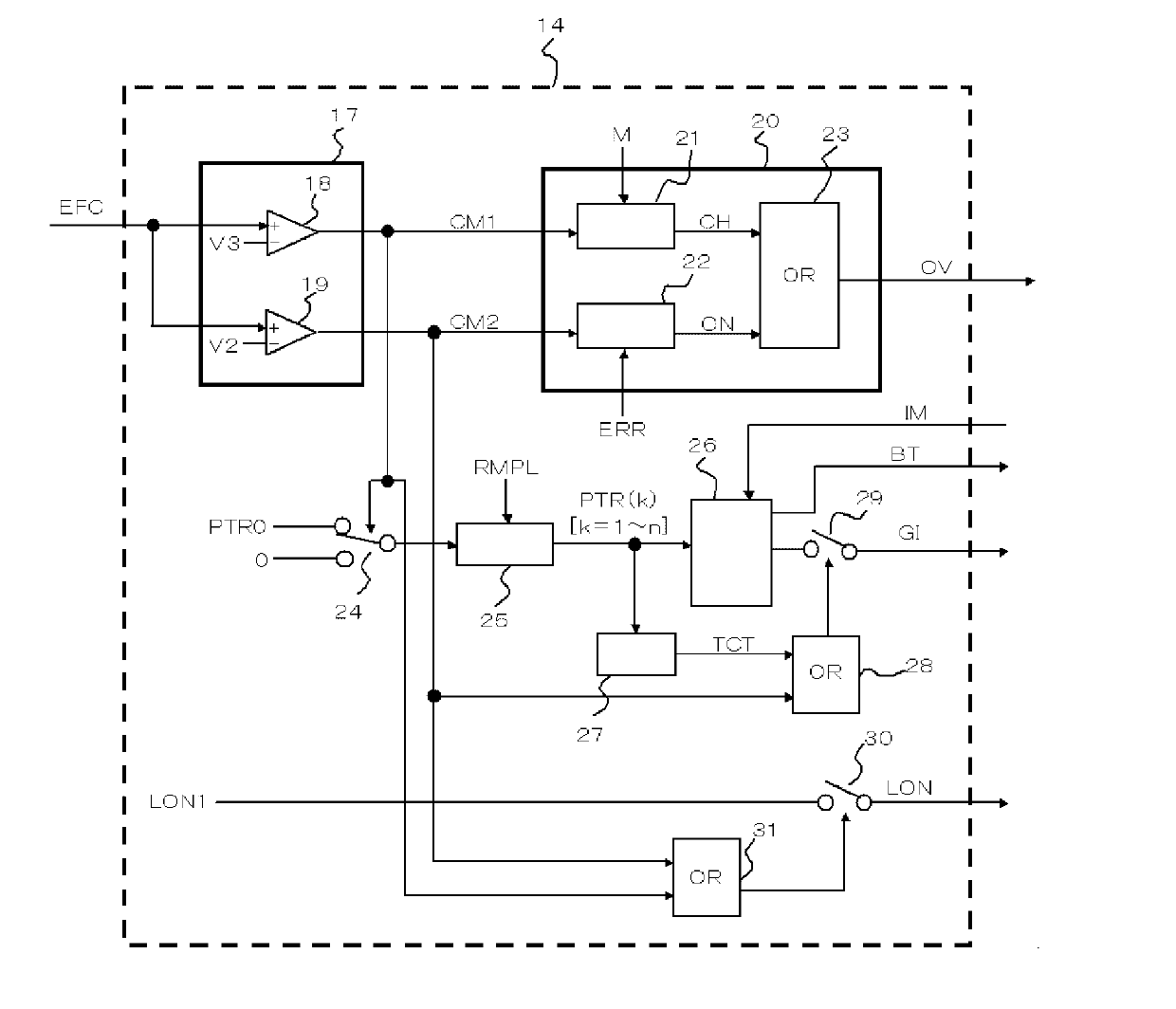

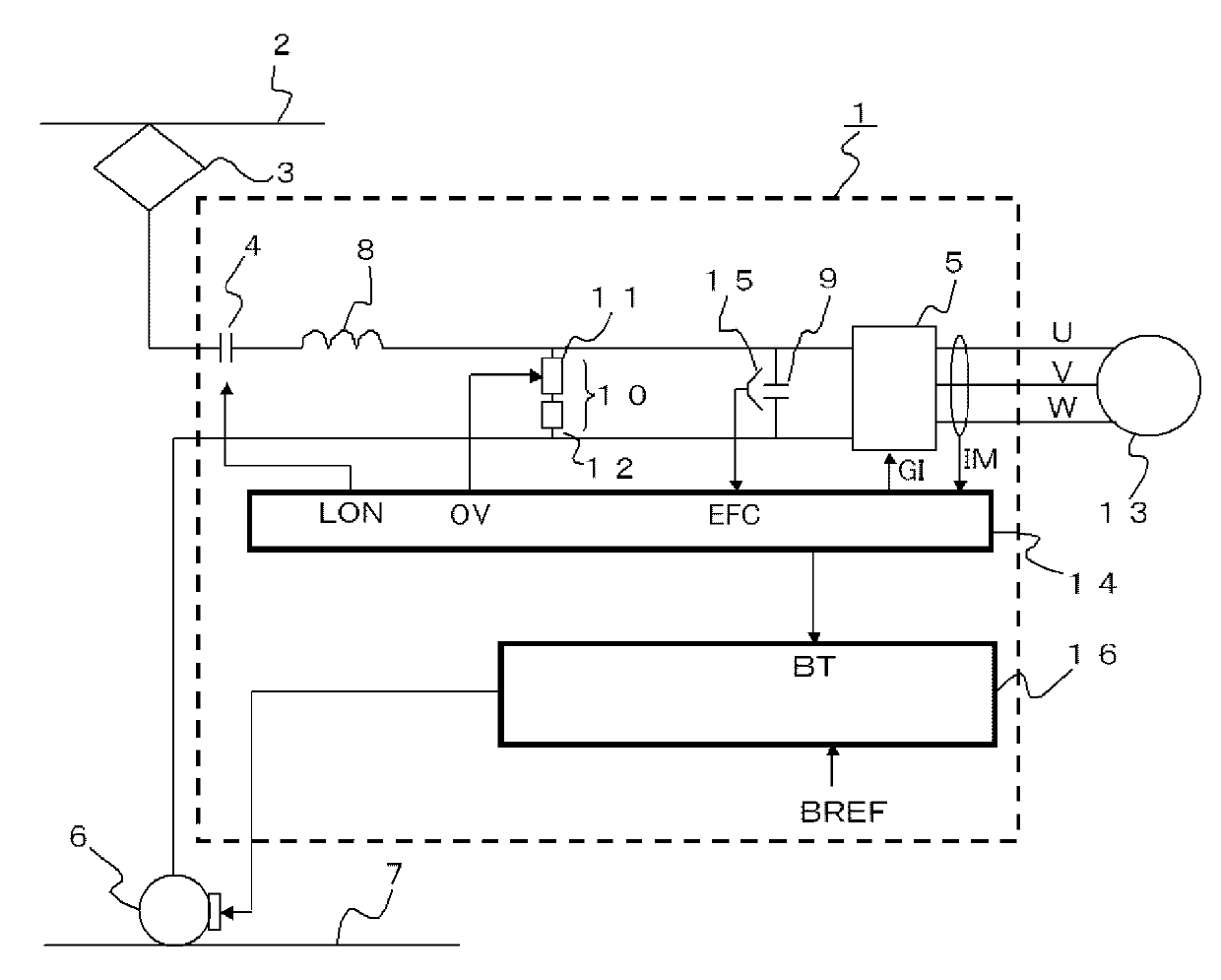

[0019] figure 1 It is a diagram showing a configuration example of the drive control device 1 for an electric vehicle according to Embodiment 1 of the present invention. Such as figure 1 As shown, the power collector 3 is brought into contact with the overhead line 2, and direct current from a substation (not shown) is input to the drive control device 1 . The DC power is input to an inverter circuit 5 as a power conversion unit via a chopper 4 as a switch unit for connecting or opening the DC power. The return current from the drive control device 1 flows through the rail 7 via the wheels 6 and returns to the negative side of the substation (not shown).

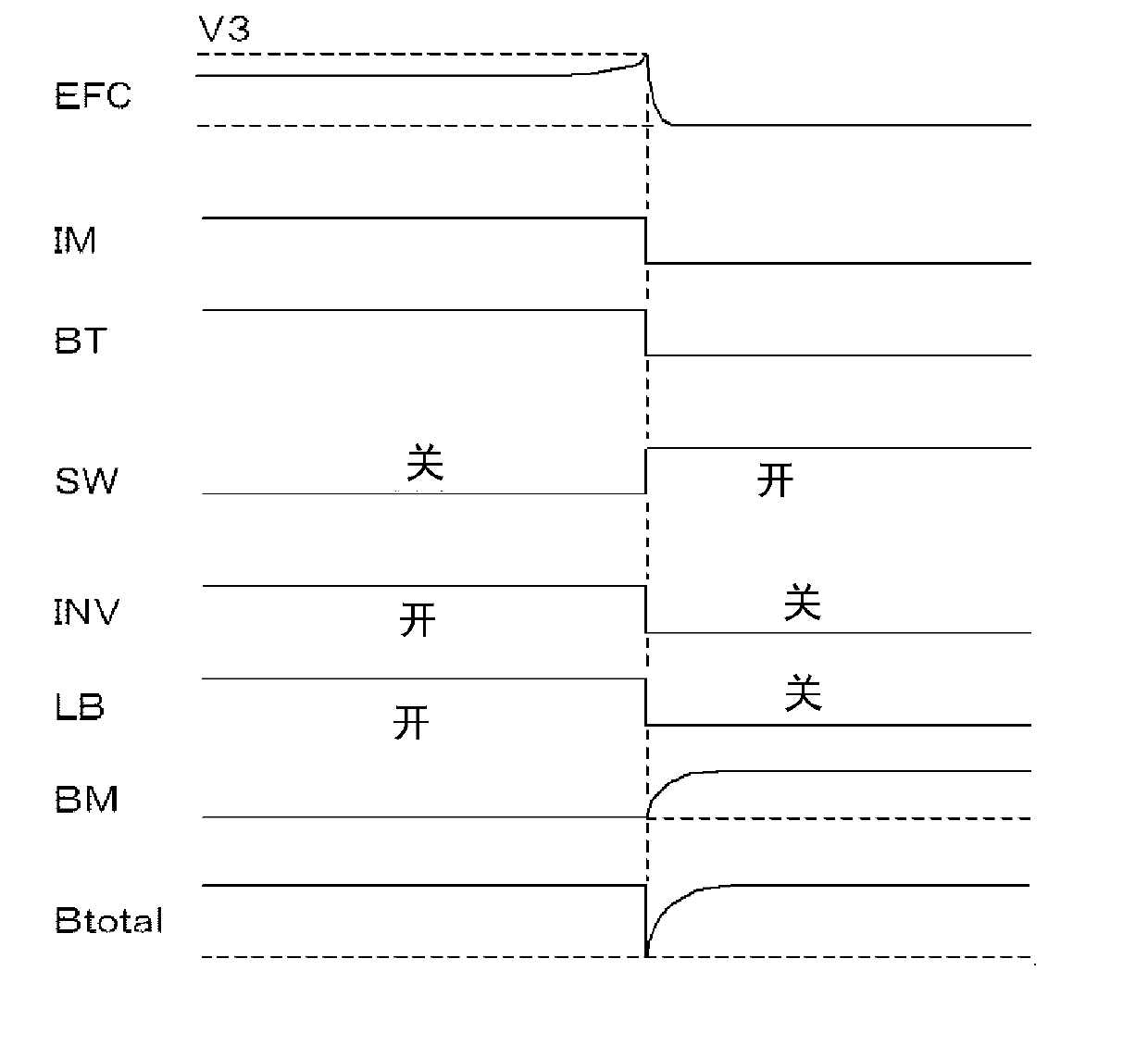

[0020] An input filter composed of a reactor 8 and a filter capacitor 9 is provided in the drive control device 1; and is used to protect the inverter circuit 5 when the regenerative load is insufficient and the input voltage rises abnormally during the regenerative braking operation, At the same time, even when the cut...

Embodiment approach 2

[0072] The drive control device for an electric vehicle according to this embodiment uses a storage battery instead of the discharge resistor 12 of the capacitor voltage regulator 10 . The configuration and operation of the other devices are the same as those in Embodiment 1, so descriptions are omitted. According to the driving control device of the electric locomotive according to the present embodiment, in addition to the effect achieved by the driving control device 1 of the first embodiment, there is also an effect that when the regenerative load is insufficient during the regenerative braking operation, the regenerative current is used to charge the battery. Charging is performed, and since the electric power charged to the storage battery can be used to drive the electric locomotive, the energy utilization efficiency when the electric locomotive is running can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com