permanent magnet rotating machines

A permanent magnet and rotating electrical machine technology, applied in synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as size limitations and reduce leakage Effects of magnetic flux, increased maximum torque, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

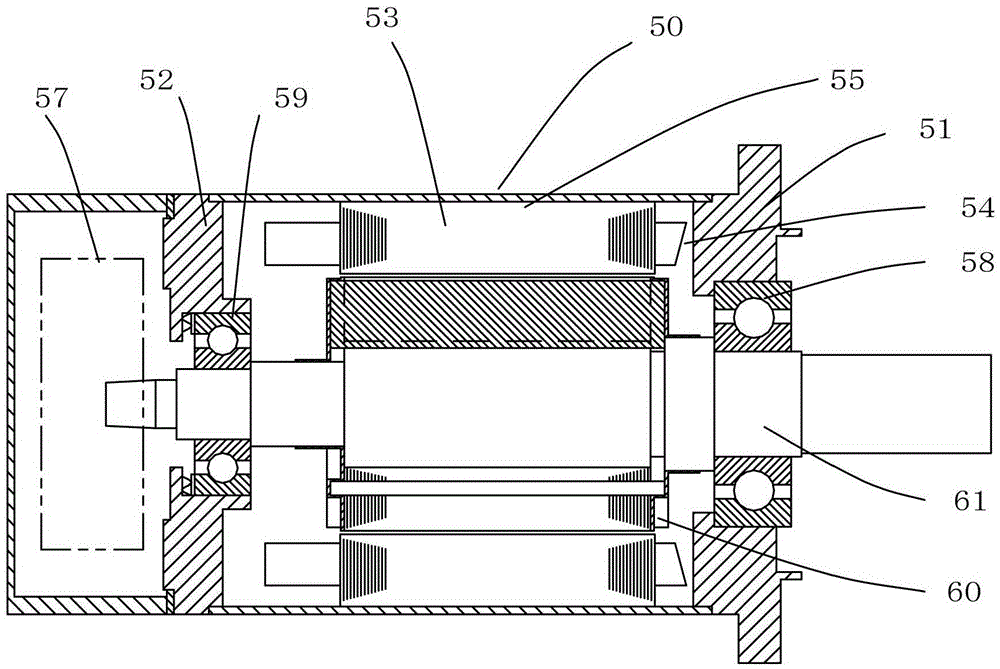

[0063] figure 1 It is an axial sectional view showing a permanent magnet type rotating electrical machine according to a first embodiment of the present invention used in an AC servo motor.

[0064] In the figure, the rotating electrical machine includes a stator and a substantially cylindrical rotor 60 rotatably supported. The rotor is rotatably supported by the load-side bracket 51 and the non-load-side bracket 52 via the load-side bearing 58 and the non-load-side bearing 59 .

[0065] An encoder unit 57 for detecting the rotational position of the rotor is provided at the non-load end portion of the shaft 61 .

[0066] The stator is composed of a stator core 53 and a stator coil 54 .

[0067] The non-load side bracket is fastened to the load side bracket with the frame 50 by unillustrated bolts.

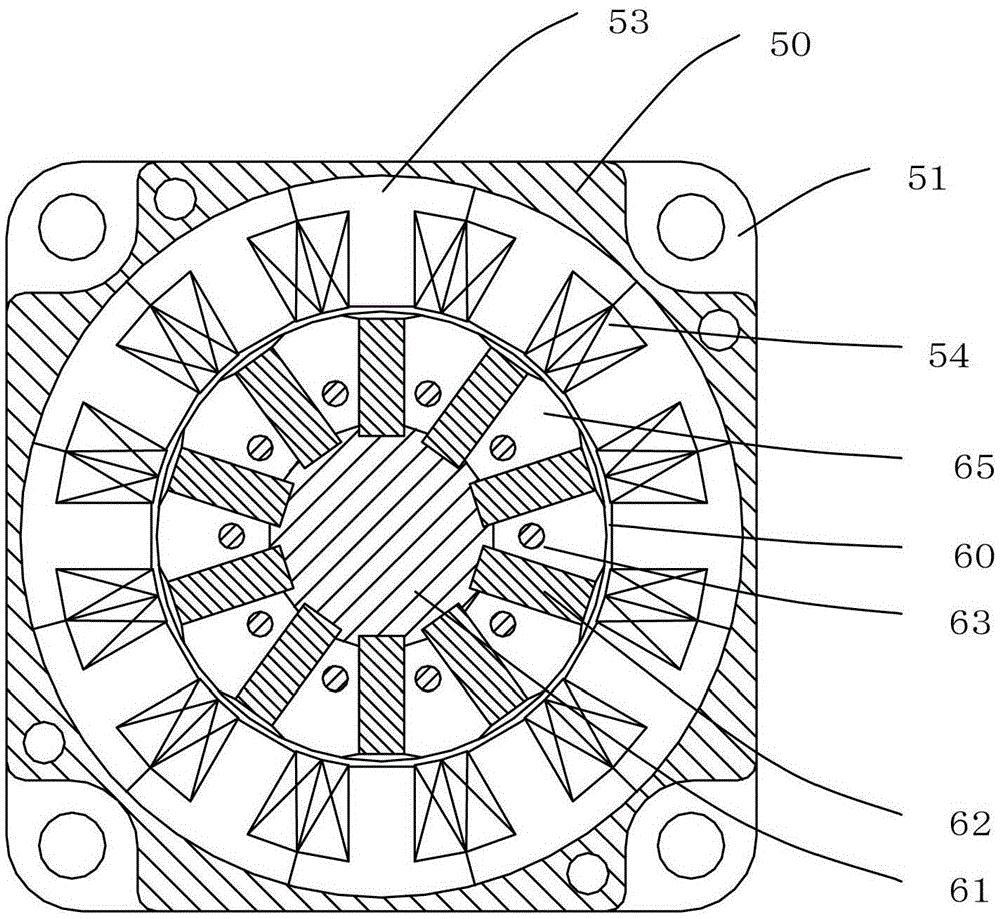

[0068] figure 2 is a radial sectional view of the rotating electric machine.

[0069] In the figure, the stator is composed of a stator core 53 divided into individual teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com