High-precision thin part processing method and auxiliary tool equipment thereof

A technology for auxiliary tooling and processing methods, which is applied in the direction of grinding workpiece supports, etc., and can solve problems such as poor rigidity of parts, clamping deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A processing method for high-precision thin parts, comprising the following steps:

[0017] 1) Perform aging treatment on thin-walled parts to remove the internal stress of the parts to prevent deformation of the parts;

[0018] 2) Carry out wire cutting on the shape, which has reached the size requirement;

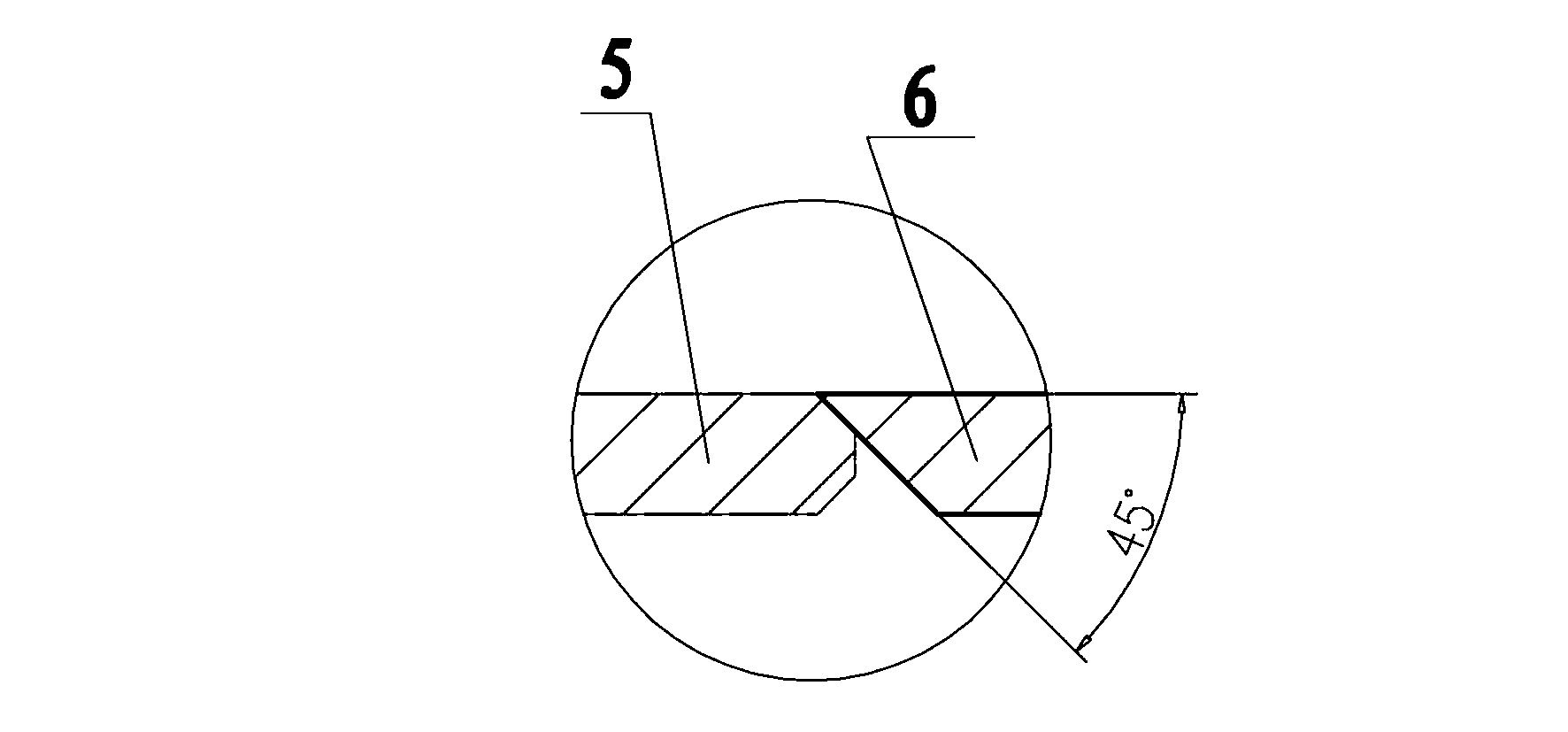

[0019] 3) Mill the end face of the non-working area of the thin-walled part into a chamfer, and clamp the thin-walled part in the auxiliary tooling. The clamping end of the auxiliary tooling is provided with a reverse Chamfer;

[0020] 4) Grinding the surface of thin-walled parts.

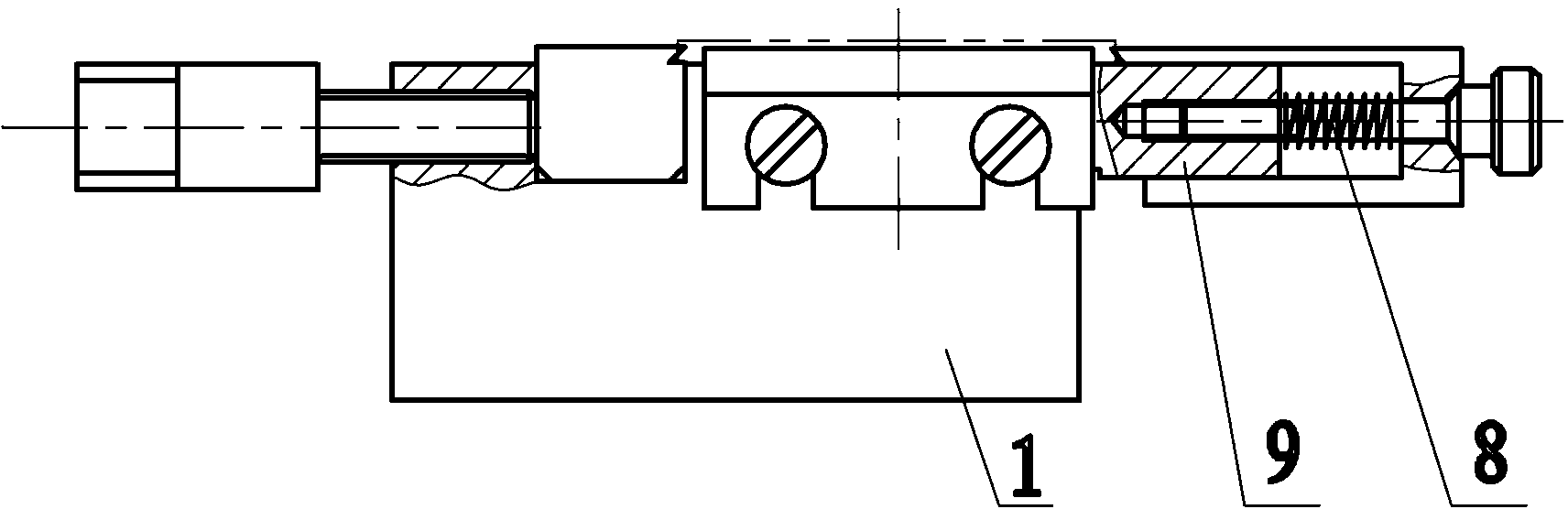

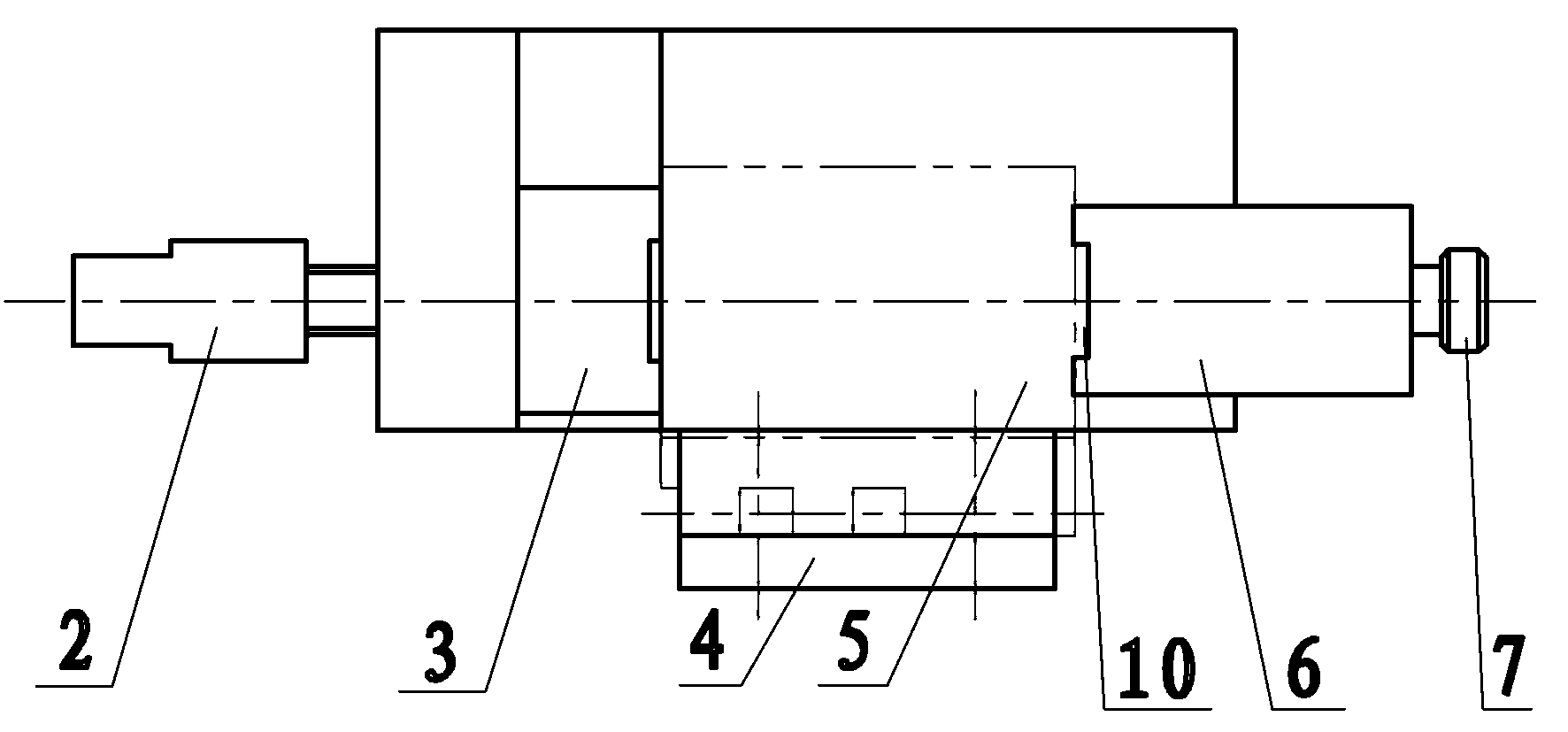

[0021] Such as Figure 1 to Figure 3 As shown, a kind of auxiliary tooling, a stopper 3 is provided in the groove at one end of the base 1, the upper surface of the stopper 3 is higher than the surface of the working area of the base 1, and the locking screw I2 is threaded from the end of the base 1 , the end of the locking screw I2 is in contact with the side of the stopper 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com