Octagonal-box-shaped pylon foot and manufacturing method thereof

A manufacturing method and box-shaped technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of large welding residual stress, inconsistent welding stress direction, affecting the quality and strength of components, etc., to achieve strong load-bearing capacity and stability, control Welding gravity lumping, guarantee the effect of external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

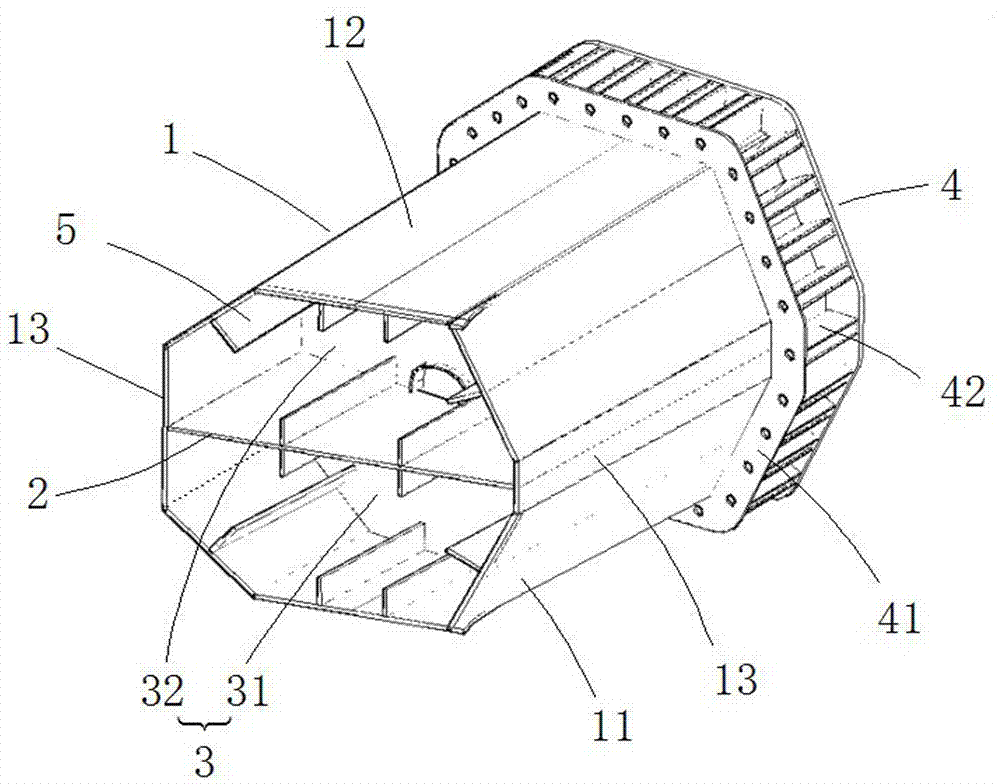

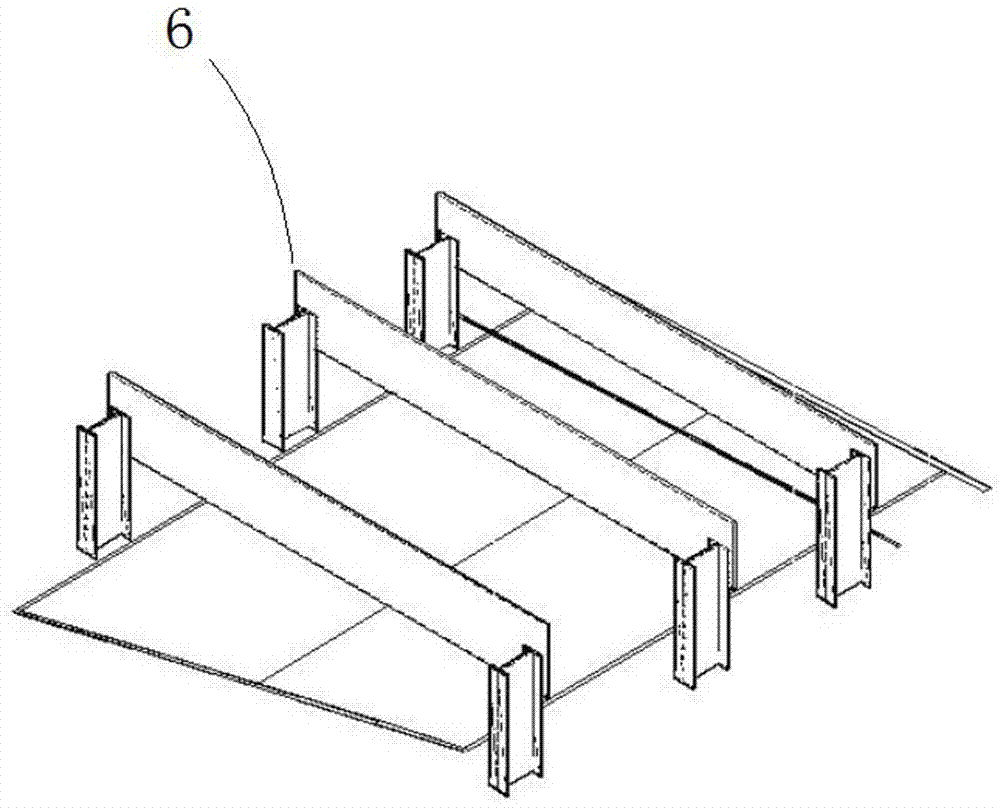

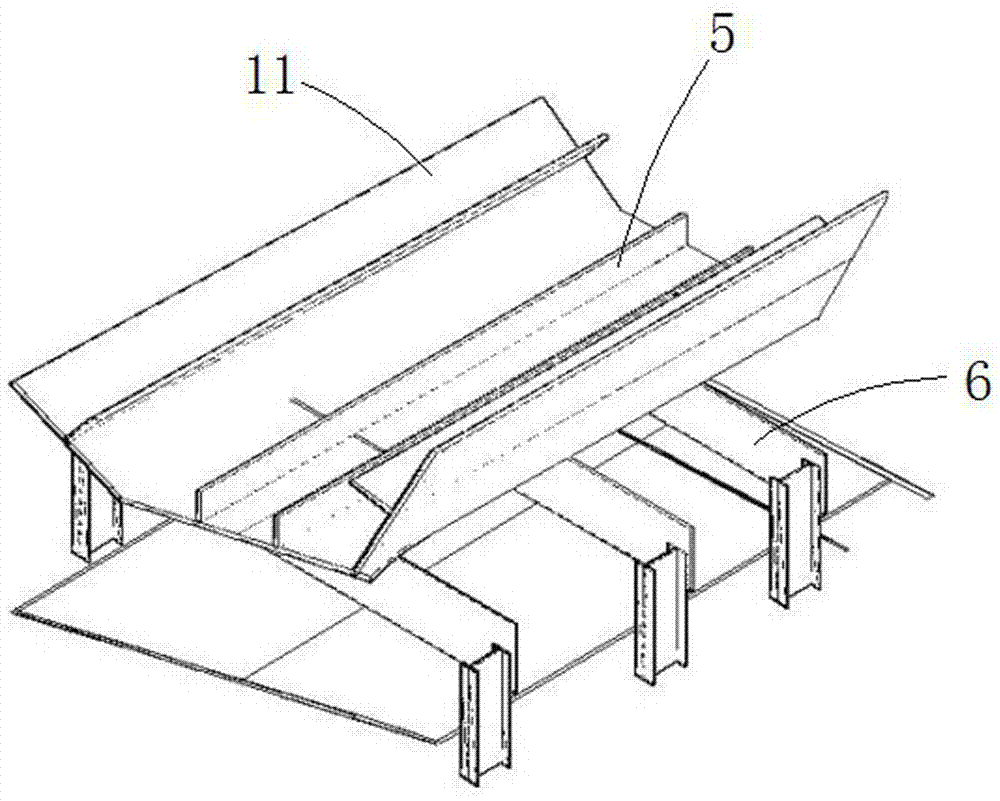

[0031] A kind of octagonal box-shaped tower column foot of the present invention, as figure 1 As shown, it includes a frame unit and a column floor unit 4. The frame unit includes a frame 1 surrounded by a group of wall panels, a central web 2 axially arranged in the frame, and a radially arranged in the frame The transverse partition 3; the column floor unit 4 is arranged at one end of the frame unit. The frame body 1 includes a lower wall plate 11, an upper wall plate 12, and a middle wall plate 13 connecting the lower wall plate 11 and the upper wall plate 12. The middle wall plate 13 is arranged at both ends of the middle web plate 2, and the The middle wall plate 13 and the middle web 2 form an H-shaped bar. The diaphragm 3 includes a lower diaphragm 31 and an upper diaphragm 32 . The column base plate unit 4 includes a set of base plates 41 arranged in parallel, and a set of intermediate support plates 42 arranged between adjacent base plates 41 . The frame unit also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com