Smit roof prism polishing and machining technology

A technology of smit roof and processing technology, which is applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of large measurement error, low precision, low one-time pass rate, etc., to reduce waste loss rate, increase production efficiency, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

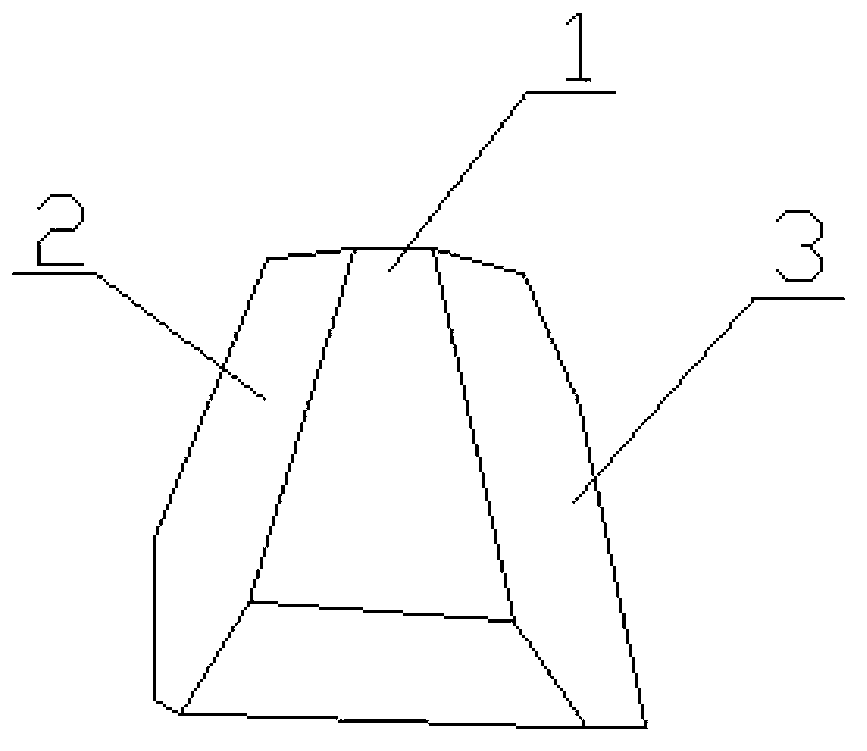

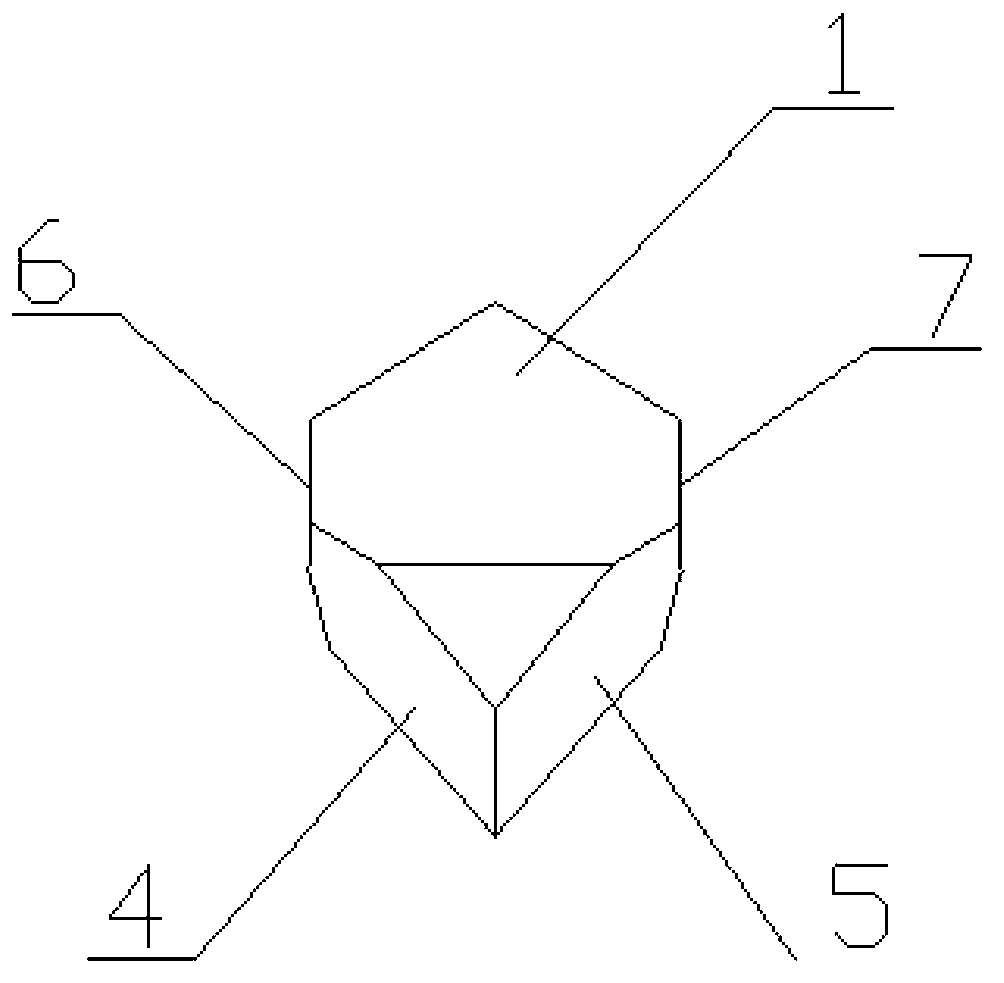

[0017] Such as figure 1 As shown, a Smit roof prism polishing process includes a prism blank body 1 and its corresponding master mold. The angle between the prism blank body 1, the master mold surface one 2 and the surface two 3 is 45°, The included angle between face three 4 and face four 5 is 90°, and face five 6 and face six 7 are parallel to each other. The specific polishing steps are as follows:

[0018] (1) Glue the finished face 5 and 6 of the prism blank body 1 to a standard 90° master mold using the photoresist process in the optical cold working process, and then polish the face 2 of the prism blank body;

[0019] (2) After the polishing of surface 2 of the prism blank body 1 is completed, the prism blank body 1 is positioned with a standard master mold, and the prism blank body 1 is glued to the surface 1 of the master mold, and then the master mold surface 2 is made of photo glue. Disk, processing surface 2 3 of the prism blank body 1;

[0020] (3) Use the surface thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com