The Method of Quickly Strengthening Masonry Structure Classrooms Using Composite Wall Panels

A masonry structure and composite wall technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems of the tight construction period of the teaching building and the difficulty of reinforcing composite wall panels, so as to shorten the reinforcement period, increase the burden, and improve thermal insulation The effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

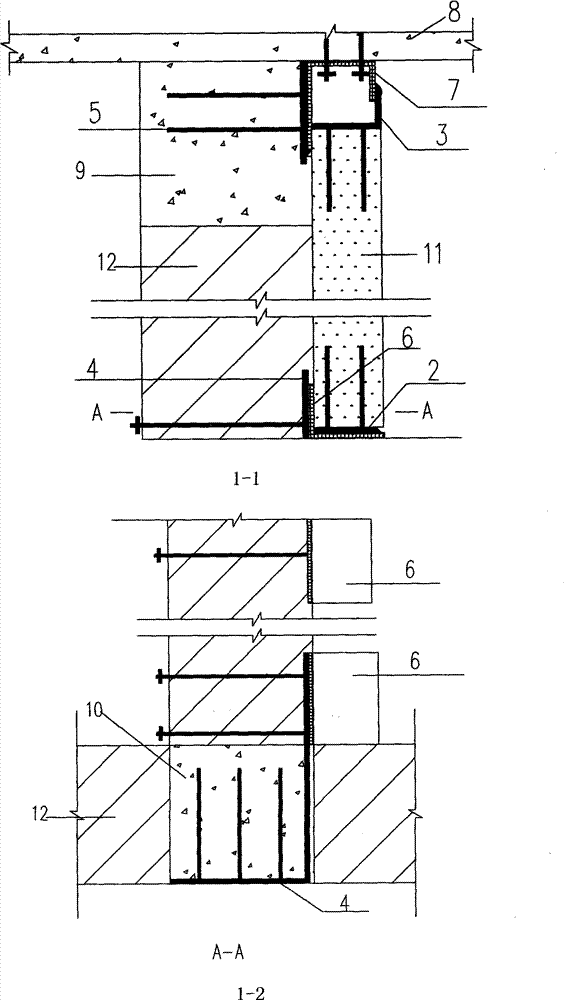

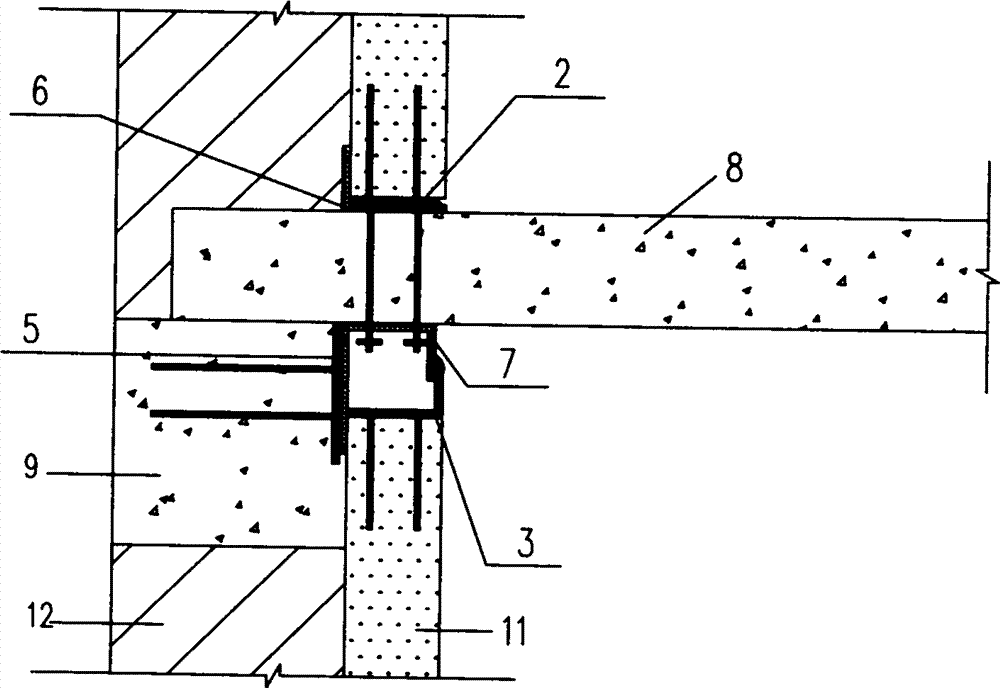

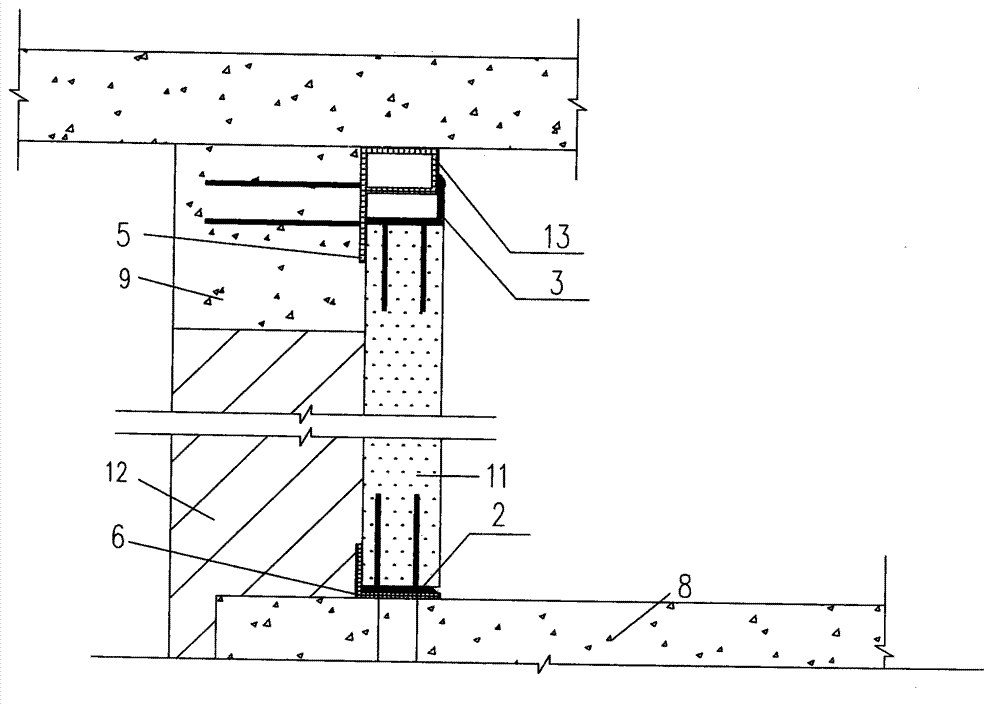

[0022] figure 2 , the second embodiment of the present invention is: the upper end of the composite wall panel 11 is connected to the ring beam 9 of the original structure, and the lower end is connected to the floor slab of the original structure. During the installation of the bottom floor, the first connectors 6 at 8 places on the original structural floor have been fixed, the second rear anchors 5 are implanted into the original structural ring beam 9, the surface of the anchor plate is flush with the surface of the original structural ring beam 9, and the second connector 7 passes through The bolt connection is fixed with the upper rear embedded part, and the protruding edge of one side of the groove is welded with the second rear anchor piece 5 . Accurately locate the installation position of the composite wall panel 11 to ensure that the upper end of the third embedded part 3 at the upper end of the composite wall panel 11 is in close contact with the first connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com