Energy-saving piston for gas engine

A gas engine, energy-saving technology, applied in the direction of engine components, machines/engines, pistons, etc., can solve problems such as the gap between economy and energy saving and environmental protection performance, high gas consumption and oil consumption, and reduced effective power, etc., to save oil energy. , the effect of low fuel consumption and oil consumption, reduction of emissions and operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

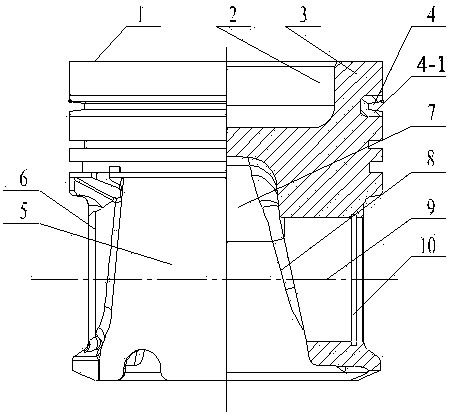

[0037] Embodiment 1: The piston is provided with three piston ring grooves sequentially from top to bottom, and the piston ring groove 4 at the uppermost end of the piston is processed by an inlay-cast wear-resistant insert ring 4-1. The contraction window 6 of the piston, the contraction window is inwardly sunken hub shape, its shape is as figure 1 , image 3 . The internal spacing of the snap ring groove 10 of the piston is 91 mm, which is set corresponding to the total length of the piston pin.

Embodiment 2

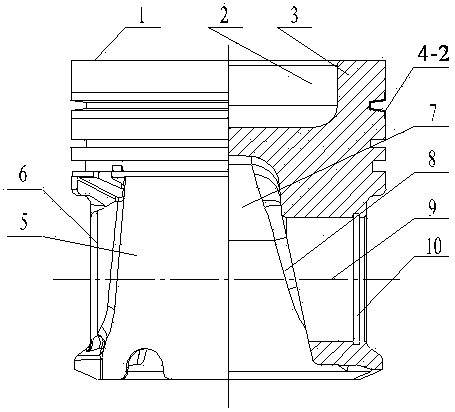

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the base material of the piston ring groove 4 at the uppermost end of the piston is consistent with the piston as a whole, and they are all cast aluminum alloys. After the processing of the piston ring groove 4 is completed, a local increase A ceramic film layer 4-2 through micro-plasma oxidation. The thickness of the ceramic film layer 4-2 is 0.010-0.040mm. Such as figure 2 hint.

Embodiment 3

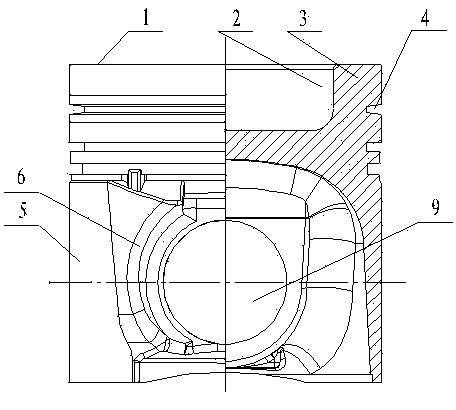

[0039] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the ceramic film layer 4-2 in the piston ring groove extends to the surface of the piston top surface 1, the piston combustion chamber 2, and the piston head 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com