Balance shaft case structure of engine

A shell structure and balance shaft technology, applied in the direction of inertial force compensation, etc., can solve problems such as difficult to accept the vibration feeling of three-cylinder engines, and achieve the effects of improving manufacturing economy, improving comfort, and reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

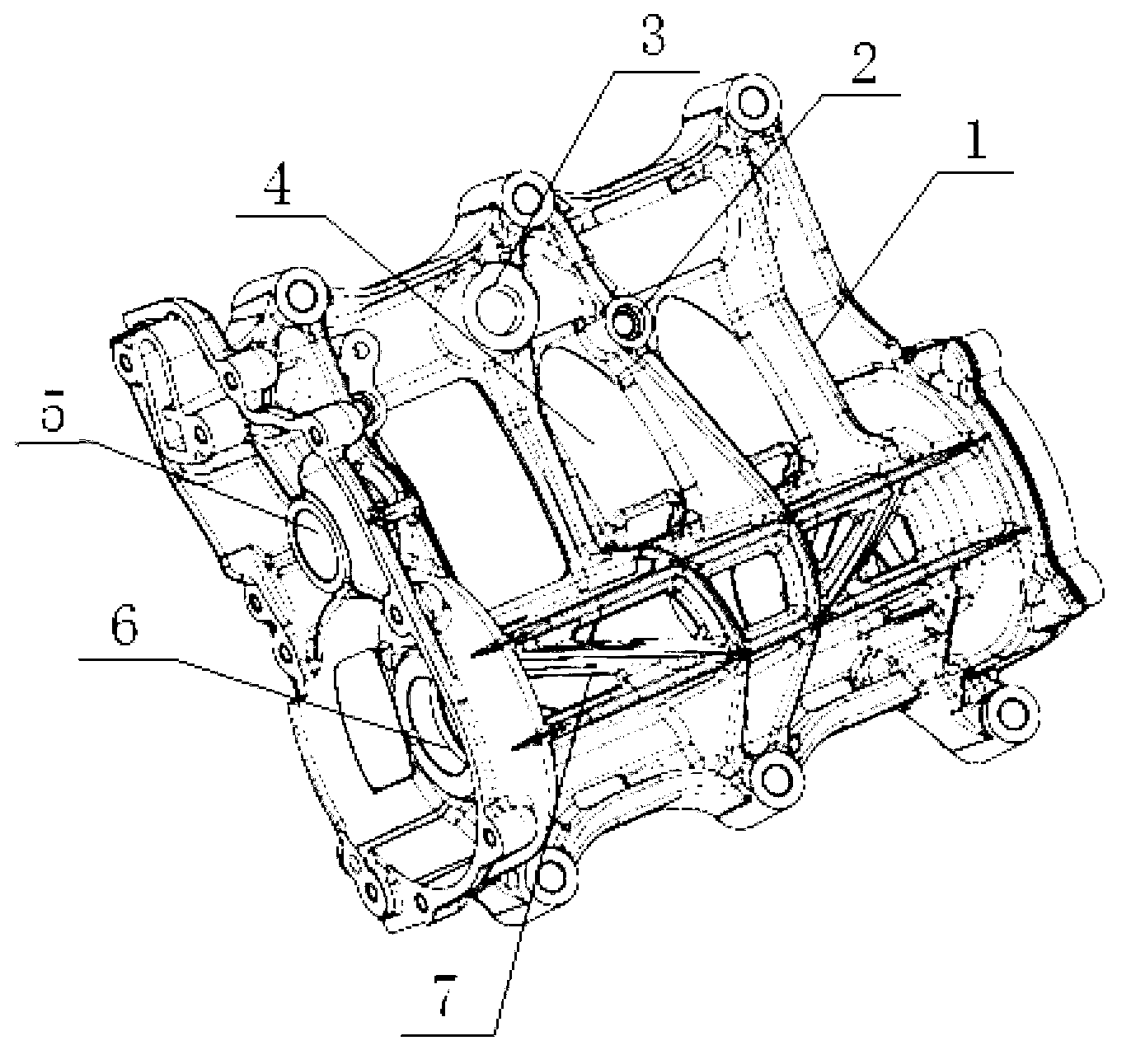

[0023] An engine balance housing, which further includes reinforced ribs and a hollowed-out weight-reducing structure, and has an oil baffle function structure, the balance shaft is installed in the shaft hole of the balance shaft housing, and the housing passes through the bolt hole 4. Fix the oil pump assembly, and install the rotating shaft of the oil pump in the hole. The oil pump supplies lubricating oil to the engine through the oil channel.

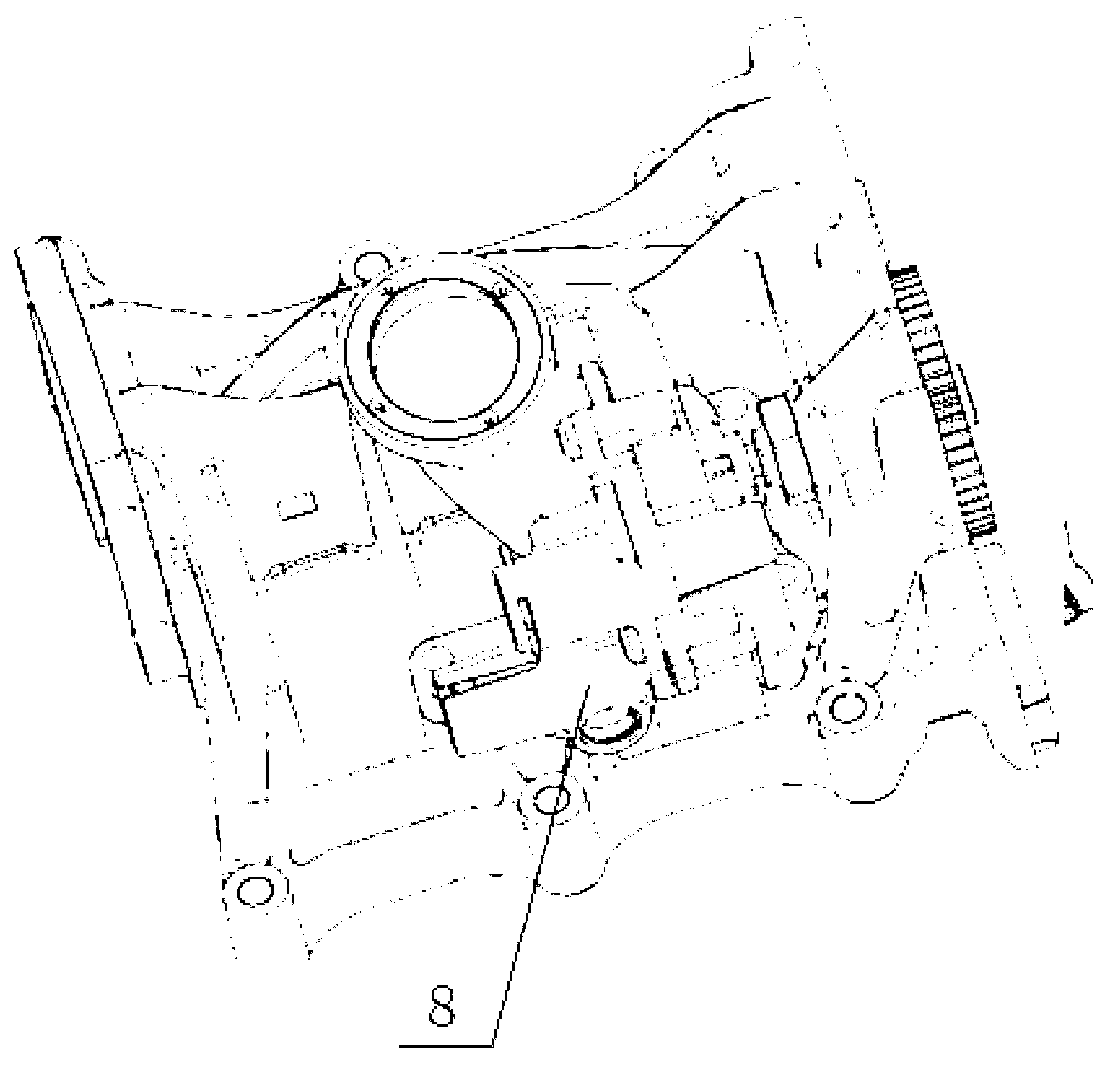

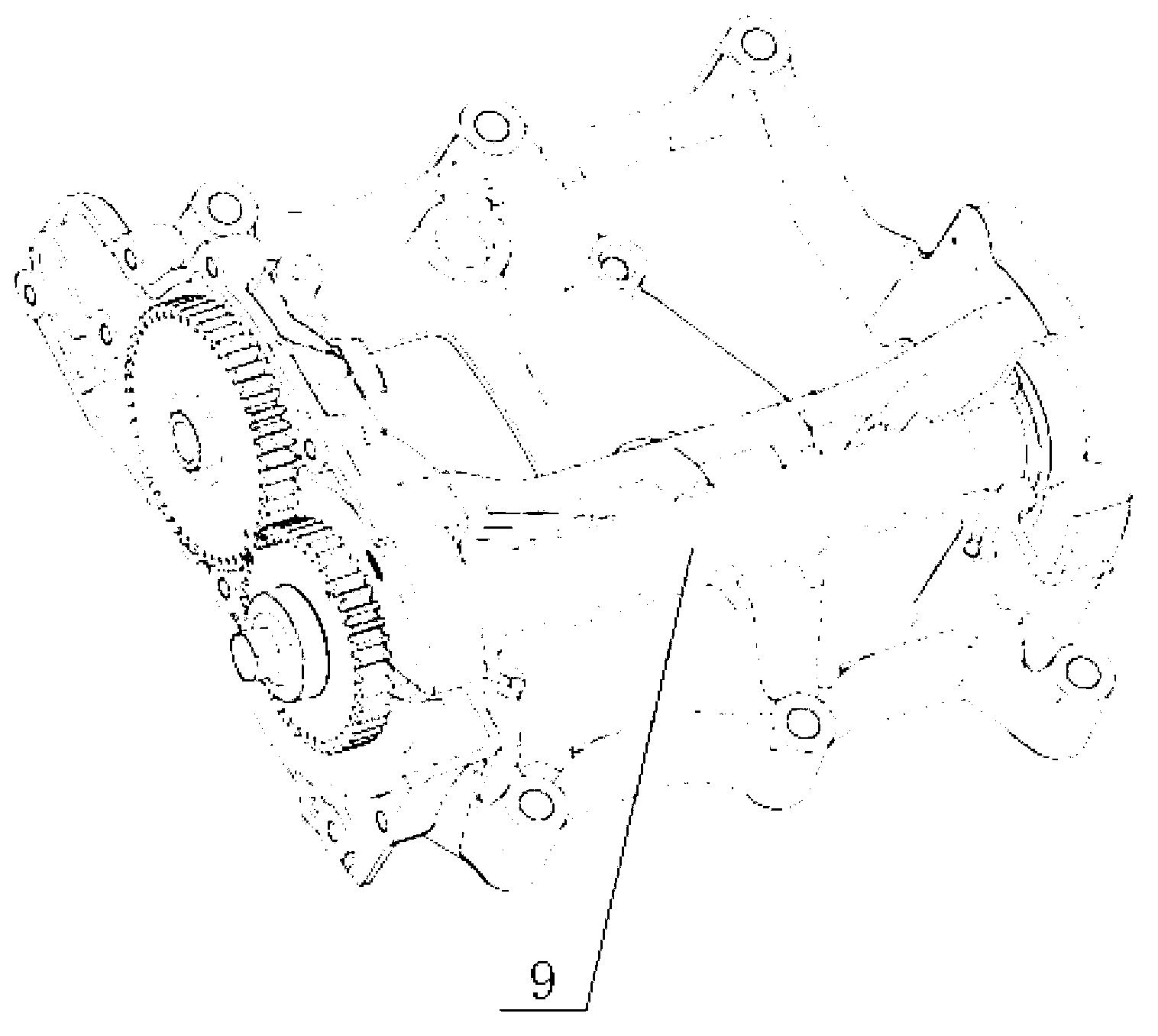

[0024] like Figure 1-3 As shown, the engine balance housing implemented by the present invention includes reinforcing ribs 1 for increasing strength; bolt holes 2 for fixing the oil pump; the oil pump provides lubricating oil through the oil channel 3-phase engine, and the oil pump drive shaft passes through the hole 5 and is driven by the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com