Continuous kernel level monitoring method and device for realizing same

A monitoring device and nuclear level technology, which is applied in the direction of measuring devices, lubrication indicating devices, engine lubrication, etc., can solve the problems of high cost, low measurement efficiency, poor measurement accuracy, etc., achieve small maintenance and reduce the influence of scattering errors , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0041] Specific embodiments 1. The continuous nuclear level monitoring method described in this embodiment is:

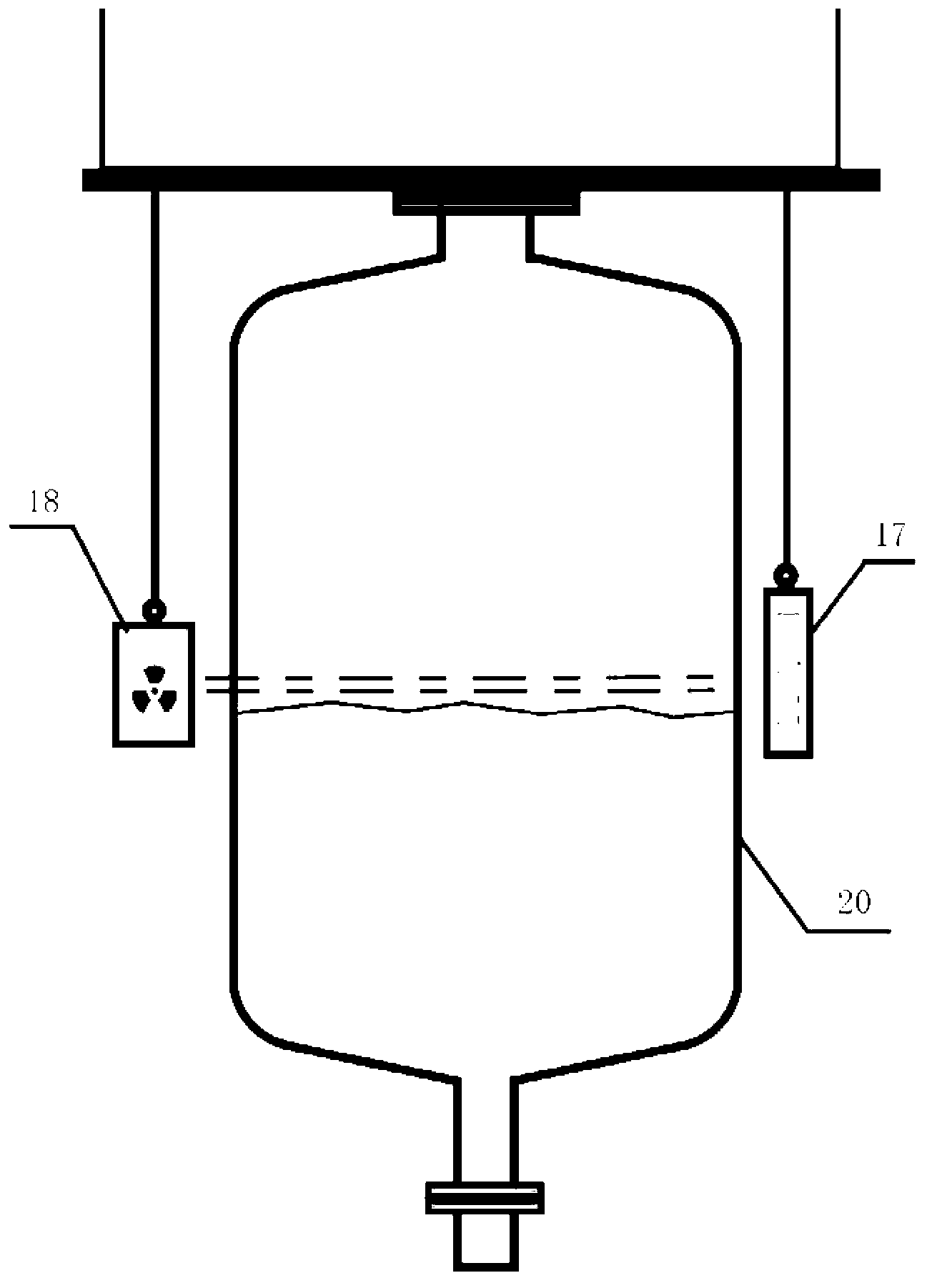

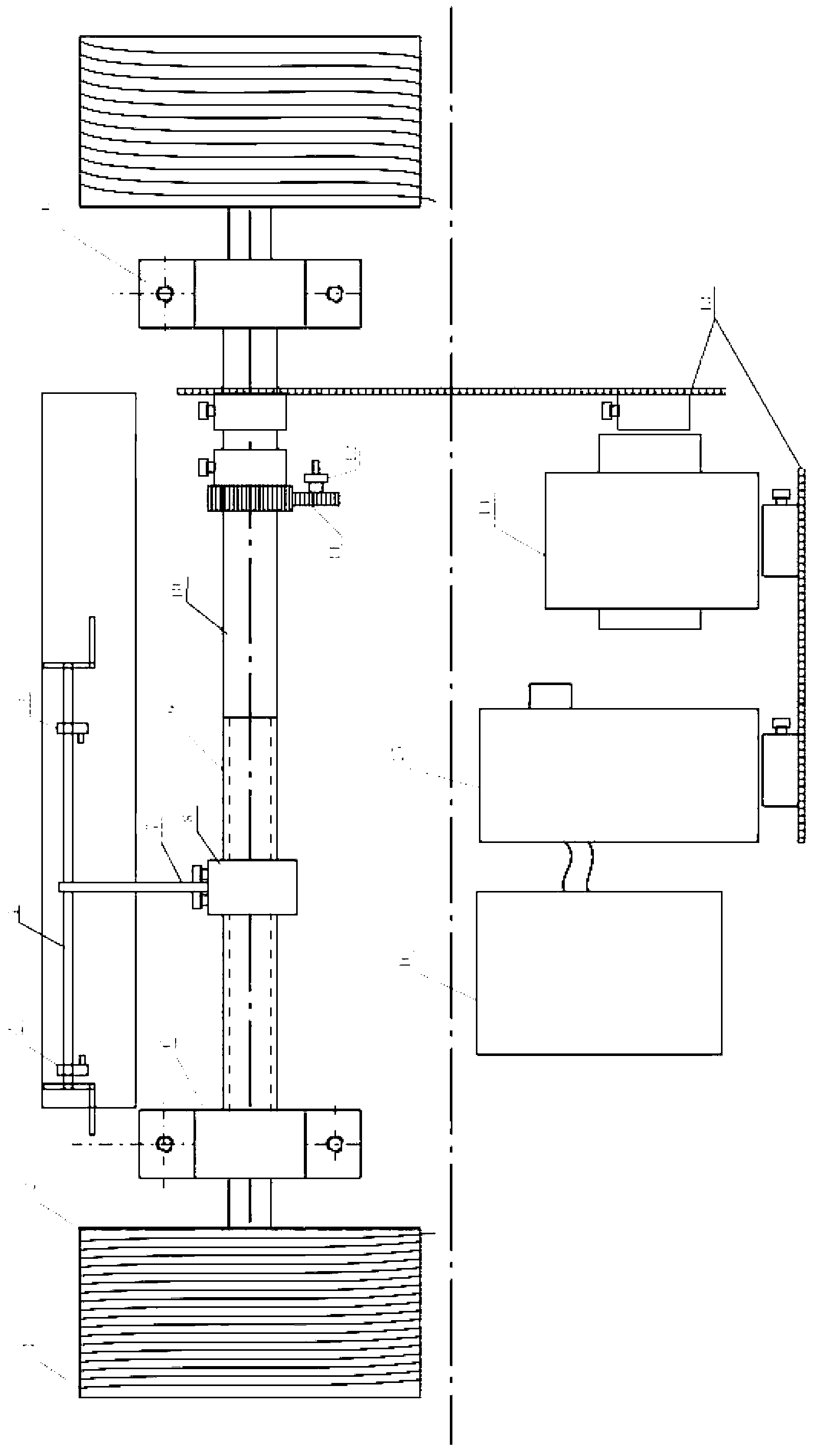

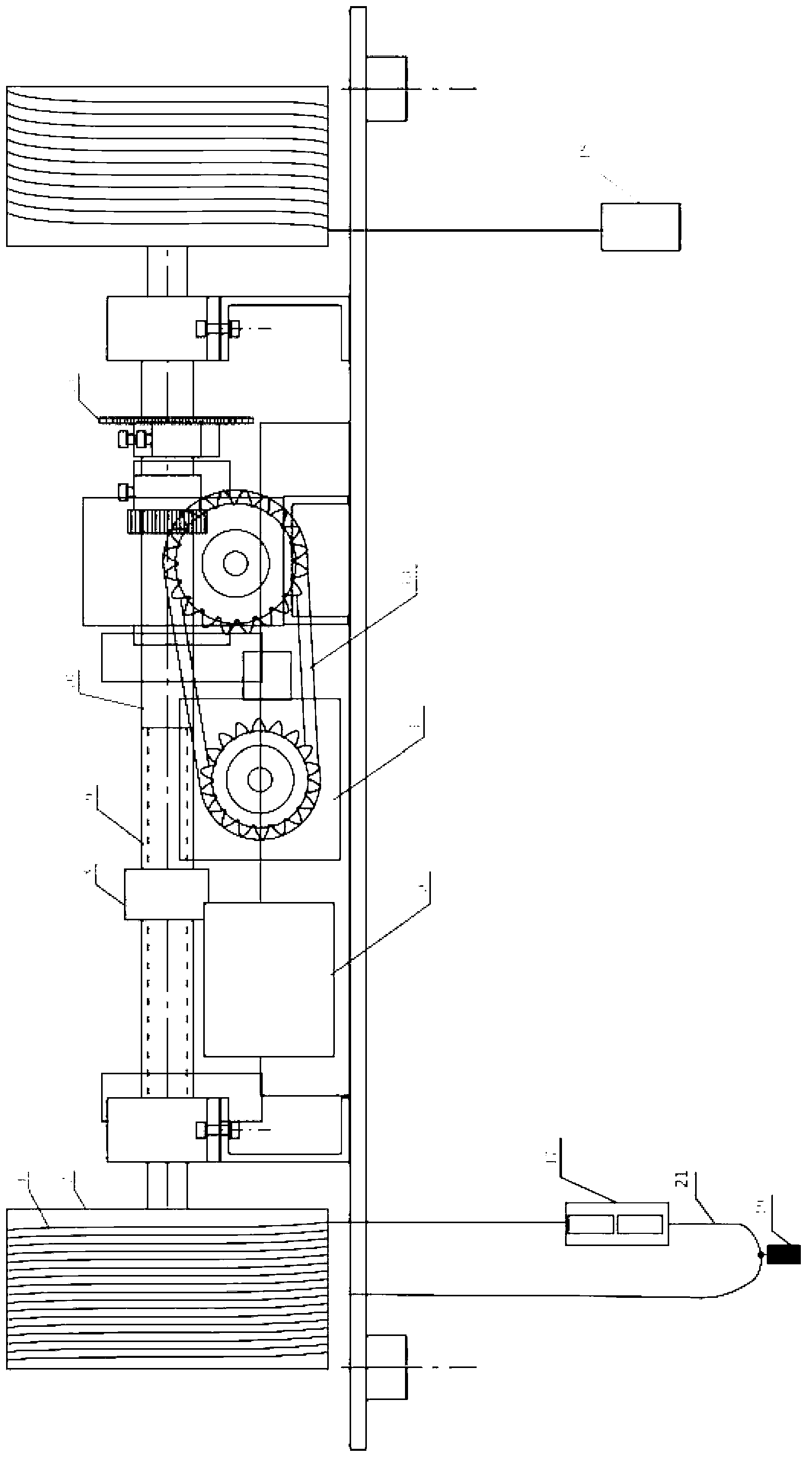

[0042] Two detectors are arranged on one side of the tank body 20 to be detected, and the two detectors are arranged in a vertical direction, the upper detector is the upper detector, and the lower detector is the lower detector; on the other side of the tank body 20 to be detected A radiation source is arranged on one side for emitting rays; the two detectors are used for receiving the rays emitted by the radiation source;

[0043] The radiation source and the detector make a one-dimensional linear motion along the vertical direction synchronously;

[0044] The signals collected by the two detectors have three combination states, and the three combination states are respectively:

[0045] State 1: The signal intensity received by the upper detector from the radiation source is greater than the threshold, while the signal intensity received by the lower detector is...

specific Embodiment approach 2

[0062] Embodiment 2. This embodiment is a further limitation of the continuous nuclear level monitoring method described in Embodiment 1. In this embodiment, the heights of the radiation source and the detector are adjusted according to the three combined states, thereby realizing The method of monitoring the level in the detected tank is as follows:

[0063] In state two, control the radiation source and the detector to move downward until the signals collected by the two detectors are state one;

[0064] In state three, control the radiation source and the detector to move upward until the signals collected by the two detectors are state one;

[0065] In state one, keep the positions of the radiation source and the detector unchanged, and take the middle position of the two detectors as the material level.

specific Embodiment approach 3

[0066] Embodiment 3. This embodiment is a further limitation of the continuous nuclear level monitoring method described in Embodiment 1. In this embodiment, the radiation signal emitted by the radiation source is γ-ray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com