Phased source consistency determining method

A determination method and consistent technology, applied in the field of seismic exploration, can solve problems such as misinterpretation of underground structures, inability to ensure that directional seismic waves can be excited by phase-controlled sources, and unavailability of phase-controlled sources, and achieve the effect of improving the signal-to-noise ratio of collected data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

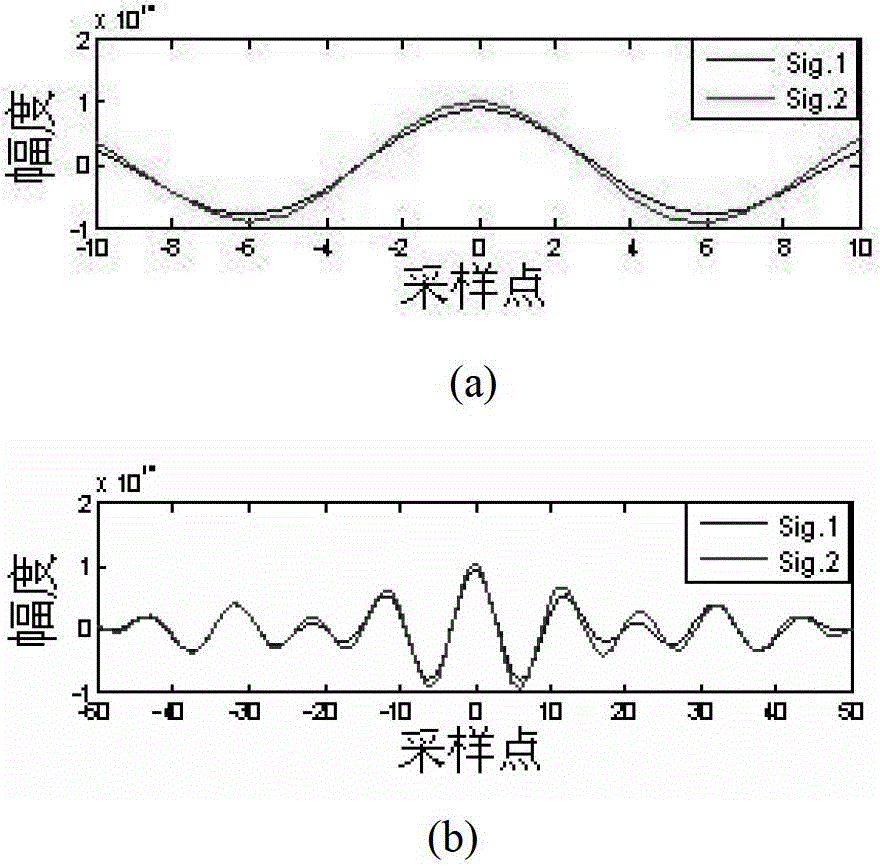

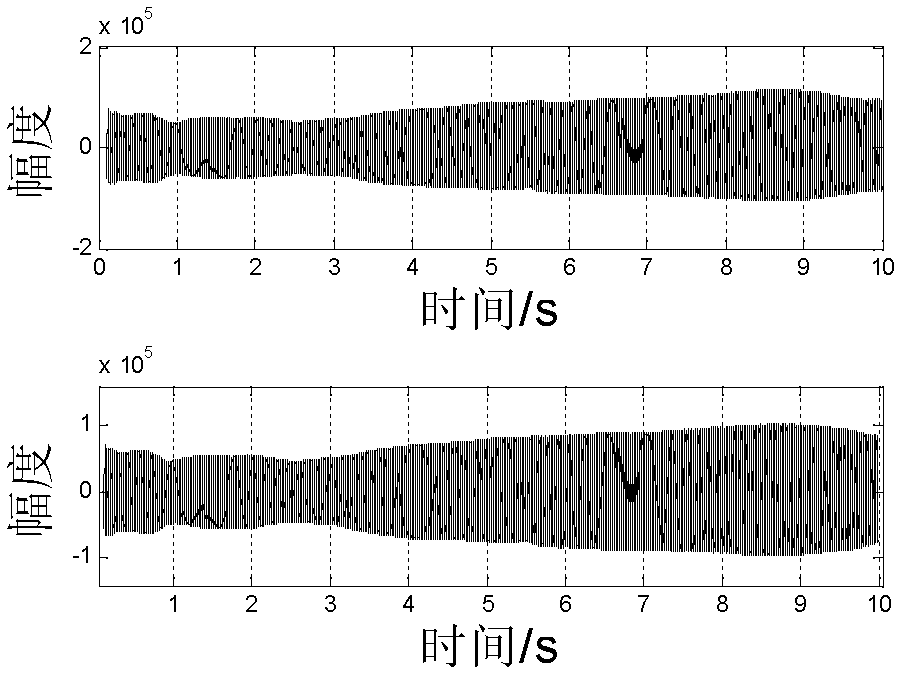

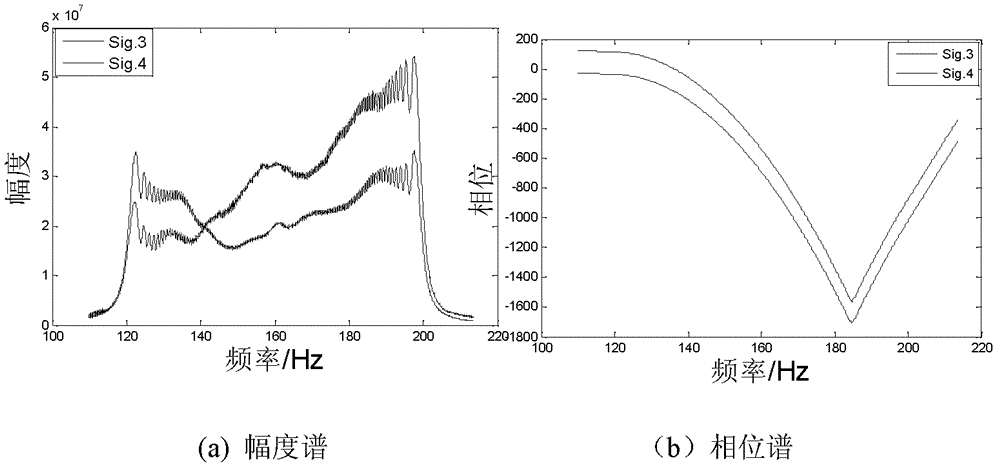

[0030] The consistency judgment method of phase-controlled vibroseis, aiming at the high-precision seismic exploration requirements of vibroseis, proposes a comprehensive quantitative evaluation method based on time-domain correlation analysis and supplemented by FFT spectrum analysis. Through this judgment method, it can be guaranteed that the phased vibrator system that meets the consistency standard has a vertical positioning accuracy error of no more than 2m; the actual signal-to-noise ratio improvement ability is compared with the theoretical value, and the signal-to-noise ratio drops by no more than 3dB; In addition to the analysis results in the time domain, the seismic source system that meets the performance requirements also provides inconsistent auxiliary quantitative judgments in the frequency domain to provide a basis for the adjustment and maintenance of the seismic source. The method of the invention provides a necessary instrument quality judgment method for ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com