Automobile steel plate spring stiffness checking method

A technology of leaf springs and spring stiffness, applied in the field of checking the stiffness of automobile leaf springs, can solve problems such as non-proportionality, large deviation between leaf spring stiffness and actual stiffness, and inability to meet design requirements, so as to save test costs and improve development efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by way of examples.

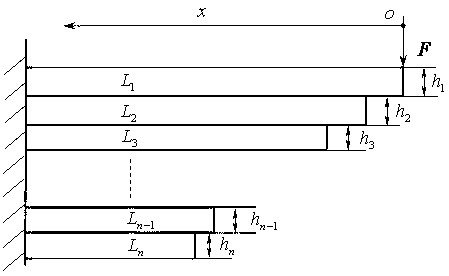

[0017] Stiffness requirements of a truck suspension leaf spring . The width of each leaf spring b =40mm; the length and thickness of each piece are as follows: L 1 =1400mm, h 1 =15mm; L 2 =1300mm, h 2 =15mm; L 3 =1200mm, h 3 =15mm; L 4 =1100mm, h 4 =12mm; L 5 =1000mm, h 5 =10mm. Modulus of elasticity of the leaf spring material Pa.

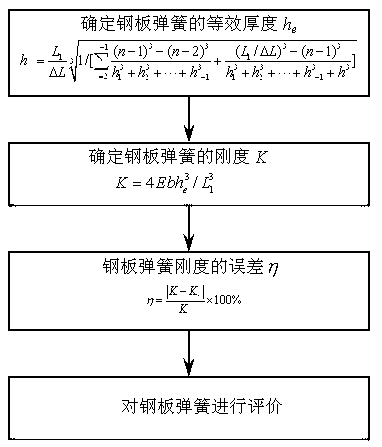

[0018] The method for checking the stiffness of the automobile leaf spring provided by the embodiment of the present invention, the calculation flow chart is as follows figure 2 As shown, the specific steps are as follows:

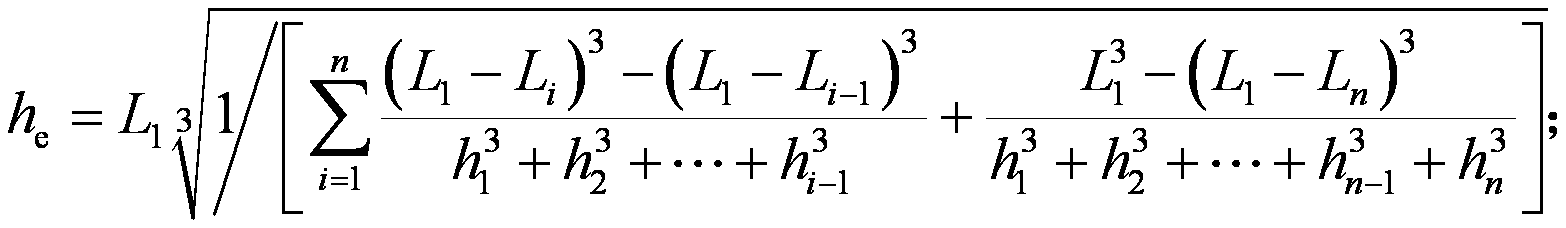

[0019] (1) According to the length and thickness of each leaf spring, that is L 1 =1400mm, h 1 =15mm; L 2 =1300mm, h 2 =15mm; L 3 =1200mm, h 3 =15mm; L 4 =1100mm, h 4 =12mm; L 5 =1000mm, h 5 =10mm to determine the equivalent thickness of the leaf spring h e for

[0020] =23.4185mm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com